Page 39 - MetalForming February 2015

P. 39

process of cold working therefore was named workhardening; we know today the correct term should be work strengthening. Unfortu- nately, the term workhardening is so common in our culture that it will remain the phrase of choice.

Today’s knowledge of deforma-

tion teaches us that a pointed

indenter under a standard load

will compress the workpiece sur-

face until a crater forms. We meas-

ure the diameter of the crater and

give it a hardness number. A small-

er crater with a higher hardness

number signifies a stronger sur-

face that resists indentations from

rough dies or in-service applica-

tions. However, in most metal-

forming applications, we see

stretch deformation through the entire thickness of the blank and not just a single surface crater. We measure the capacity for stretch forming using a tensile test, the FLC, stretch-bend and other formability tests.

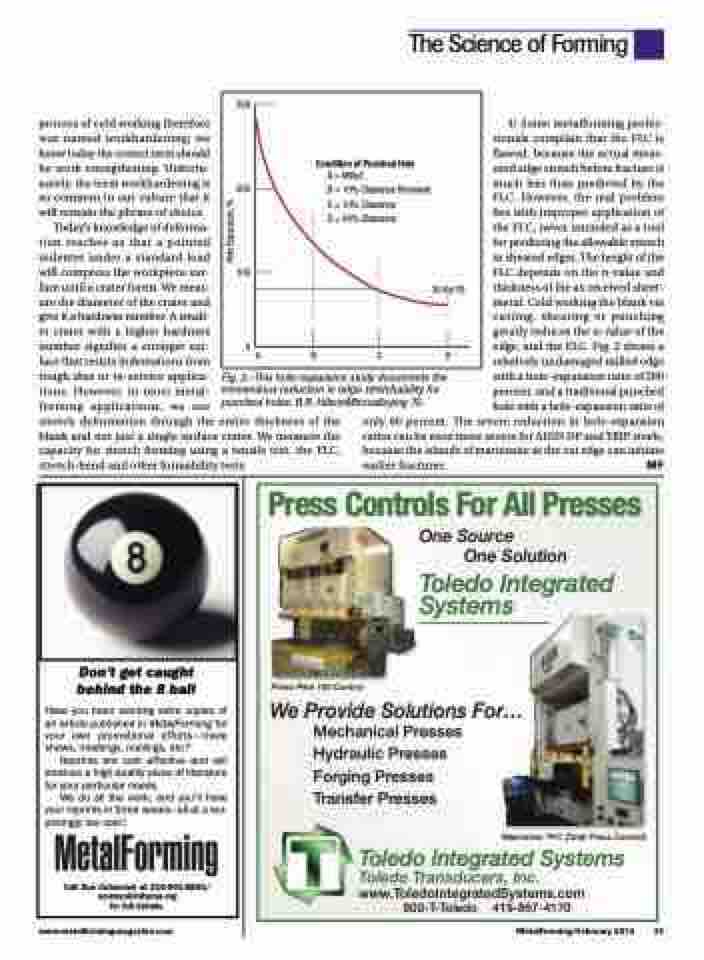

4) Some metalforming profes- sionals complain that the FLC is flawed, because the actual meas- ured edge stretch before fracture is much less than predicted by the FLC. However, the real problem lies with improper application of the FLC, never intended as a tool for predicting the allowable stretch in sheared edges. The height of the FLC depends on the n-value and thickness of the as-received sheet- metal. Cold working the blank via cutting, shearing or punching greatly reduces the n-value of the edge, and the FLC. Fig. 2 shows a relatively undamaged milled edge with a hole-expansion ratio of 280 percent, and a traditional punched hole with a hole-expansion ratio of

only 80 percent. The severe reduction in hole-expansion ratios can be even more severe for AHSS DP and TRIP steels, because the islands of martensite at the cut edge can initiate

Fig. 2—This hole-expansion study documents the tremendous reduction in edge stretchability for punched holes. R.R. HilsonMicroalloying 75.

earlier fractures.

MF

The Science of Forming

300

200

100

Condition of Punched Hole

A = Milled

B = 10% Clearance Removed C = 10% Clearance

D = 40% Clearance

30 Ksi YS

0

ABCD

Press Controls For All Presses

One Source

One Solution

Toledo Integrated Systems

Press Pilot 150 Control

We Provide Solutions For...

Mechanical Presses Hydraulic Presses Forging Presses Transfer Presses

Maximizer TPC (Total Press Control)

Toledo Integrated Systems Toledo Transducers, Inc.

www.ToledoIntegratedSystems.com 800-T-Toledo 419-867-4170

Don’t get caught

Have you been wanting extra copies of an article published in MetalForming for your own promotional efforts—trade shows, meetings, mailings, etc?

behind the 8 ball

Reprints are cost effective and will produce a high-quality piece of literature for your particular needs.

We do all the work, and you’ll have your reprints in three weeks—all at a sur- prisingly low cost!

Call Sue Cubranich at 216-901-8800/ scubranich@pma.org

for full details.

www.metalformingmagazine.com

MetalForming/February 2015 37

Hole Expansion, %