Page 38 - MetalForming February 2015

P. 38

The Science of Forming

By Stuart Keeler

Modern Forming Needs Upgraded Language

Sheetmetal forming is becoming more complex as new higher-strength steels find use for consolidat- ing multiple stampings into one, with tighter dimen- sional tolerances and increased productivity. Too often these advances become hindered by the use of old ter- minology and misunderstanding of process problems. I describe four such problems here.

0.30 0.25 0.20 0.15 0.10 0.05

0

0 5 10 15 20 25 30 Engineering Strain (%)

n-va Measur

lue ement

Range

TRIP 350/600 DP 350/600 HSLA 350/450

1) Misunderstanding of steel properties can occur due to use of different identification systems in different areas of the world. For example, does high-strength low- alloy (HSLA) 450 MPa mean a yield strength of 450 MPA,

or a tensile strength of 450 MPa? Unfortunately, both can be correct. This steel has been listed by yield strength

in North America and Europe but by tensile strength in Asia and the Pacific Rim. No problems existed when the steel was made and used in the same country. However, steel now made in one part of the world and then shipped

to another area for production of stampings can create confusion. All advanced high-strength steels (AHSS) are specified by tensile strength throughout the world, but many steel users must order by yield strength.

One solution promoted by WorldAutoSteel (the technical division of Worldsteel) is use of a label printed with three pieces of information: steel type, plus yield strength and tensile strength values in MPa. One coil of steel could be labeled HSLA 350/450, and another coil (of AHSS) might be labeled TRIP 350/600. The user knows exactly the ordered properties of the steel. While both steels have equal yield strengths, their tensile strengths are different. By calculating the TS/YS ratio, some information about the workhardening exponent (n-value) can be obtained. The ratios are 1.29 for the HSLA and 1.71 for TRIP steels.

2) I often hear metalformers say that, “We convert uniform elongation into n-value because it is easier than curve-fitting to a line of data points.” The better option is to compute uni- form elongation from the n-value. The uniform elongation depends only on one data point—ultimate tensile strength.

Stuart Keeler (Keeler Technologies LLC) is known worldwide for his discovery of forming limit diagrams, development of circle-grid analysis and implementa- tion of other press-shop analysis tools. Keeler’s metal- forming experience includes 24 years at National Steel Corporation and 12 years at The Budd Company Technical Center, enabling him to bring a very diverse background to this column and to the seminars he teaches for PMA.

Keeler Technologies LLC

P.O. Box 283 | Grosse Ile, MI 48138 Fax: 734/671-2271 keeltech@comcast.net

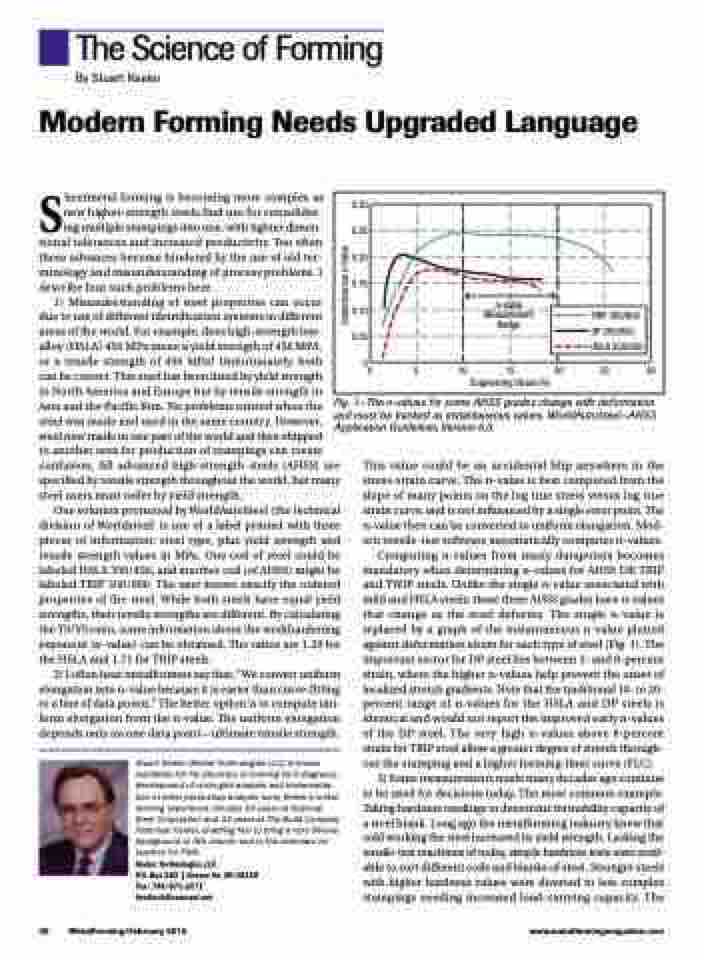

Fig. 1—The n-values for some AHSS grades change with deformation and must be tracked as instantaneous values. WorldAutoSteel—AHSS Application Guidelines Version 5.0.

This value could be an accidental blip anywhere in the stress-strain curve. The n-value is best computed from the slope of many points on the log true stress versus log true strain curve, and is not influenced by a single error point. The n-value then can be converted to uniform elongation. Mod- ern tensile-test software automatically computes n-values.

Computing n-values from many datapoints becomes mandatory when determining n-values for AHSS DP, TRIP and TWIP steels. Unlike the single n-value associated with mild and HSLA steels, these three AHSS grades have n-values that change as the steel deforms. The single n-value is replaced by a graph of the instantaneous n-value plotted against deformation strain for each type of steel (Fig. 1). The important sector for DP steel lies between 3- and 8-percent strain, where the higher n-values help prevent the onset of localized stretch gradients. Note that the traditional 10- to 20- percent range of n-values for the HSLA and DP steels is identical and would not report the improved early n-values of the DP steel. The very high n-values above 8-percent strain for TRIP steel allow a greater degree of stretch through- out the stamping and a higher forming-limit curve (FLC).

3) Some measurements made many decades ago continue to be used for decisions today. The most common example: Taking hardness readings to determine formability capacity of a steel blank. Long ago the metalforming industry knew that cold working the steel increased its yield strength. Lacking the tensile-test machines of today, simple hardness tests were avail- able to sort different coils and blanks of steel. Stronger steels with higher hardness values were diverted to less complex stampings needing increased load-carrying capacity. The

36 MetalForming/February 2015

www.metalformingmagazine.com

Instantaneous n-Value