|

|

|

| Sponsored |

| Maximize Uptime and Improve Productivity |

| AMSOIL

Industrial lubricants maximize uptime while our Certified Lubrication

Specialists (CLS) help you eliminate inefficiencies and develop

solutions that save you money. Learn more about how AMSOIL Industrial is

the choice for your Metal Stamping operation. |

|

|

|

|

|

|

|

|

|

| Trumpf Focused on Sustainability in Metal Fabricating |

|

|

|

|

| The

Trumpf InTech inhouse exhibition in Germany showcased solutions

designed to boost sustainability and productivity in connected

manufacturing. Alongside technologies to lower the consumption of

materials, energy and cutting gas, the exhibition also featured

processes to reduce or eliminate the use of environmentally harmful

chemicals in automotive manufacture. |

|

|

|

|

|

|

|

|

|

|

| Sponsored |

| Cut 3D Parts After Forming |

| Cut 3D parts after they’ve been formed. Bent tubes, hydroformed components, tubular assemblies, deep drawn parts, flat or stamped plates can be trimmed and cut with maximum efficiency and excellent cut quality every time. The LT-Free replaces traditional machining operations and allows you to produce finished parts in a single work cycle. |

|

|

|

|

|

|

|

|

|

|

|

| Smart Programming Software Delivers Big Robotic Welding Gains |

| Van

Hool employs robotic welding to assemble chassis for buses and other

large vehicles. Artificial-intelligence-based software learns as it goes

to increasingly improve offline robot programming, netting significant

increases in arc welding throughput. |

|

|

|

|

|

|

|

|

|

| Sponsored |

| Free on April 25: MF LIVE on the Shop Floor Targets Automation |

| Sign up for MetalForming LIVE on the Shop Floor, a free, online event taking place April 25 that deep dives into recent shop-floor robotics applications. MF LIVE on the Shop Floor includes interviews with executives from Clips & Clamps Industries (Plymouth, MI) and Sukup Manufacturing Co. (Sheffield, IA) who will discuss their companies’ efforts to employ automation technology, and present videos featuring their technology in action. And, we’ll assemble a live panel to discuss automation implementation and answer attendee questions. |

|

|

|

|

|

|

|

|

|

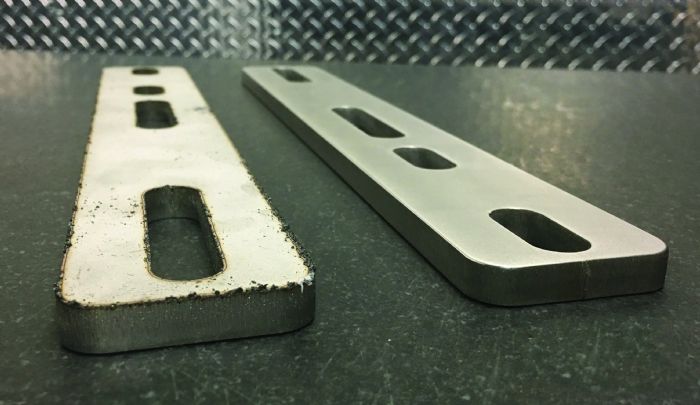

| New Tools Enhance Tube-Laser Performance |

|

|

|

|

| BLM

Group, Novi, MI, has enhanced its line of tube lasers with its patented

Active Tools technology, several features that promise to help the

machines automatically adapt process parameters for optimal results. |

|

|

|

|

|

|

|

|

|

|

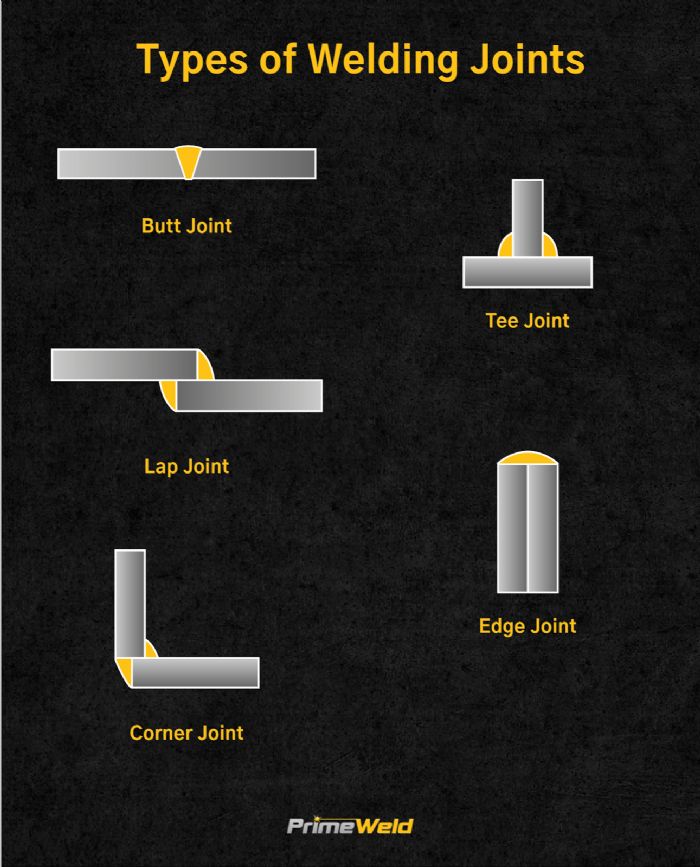

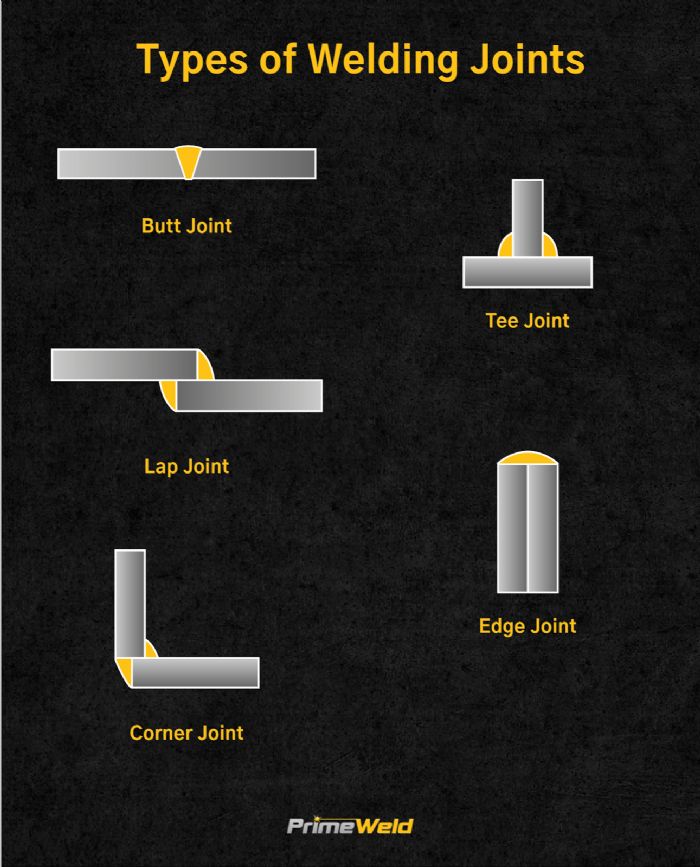

| Guide to Weld Joints and Their Applications |

| PrimeWeld

has developed A Guide to Weld Joints, including information on butt,

tee, lap, edge and corner joints. The guide, offered in a blog at

www.primeweld.com/blogs/news/weld-joints-guide, covers the difference

between welds and weld joints, an explanation of the five basic joints,

pros and cons of each type of joint, and possible applications of each

type. |

|

|

|

|

|

|

|

|

|

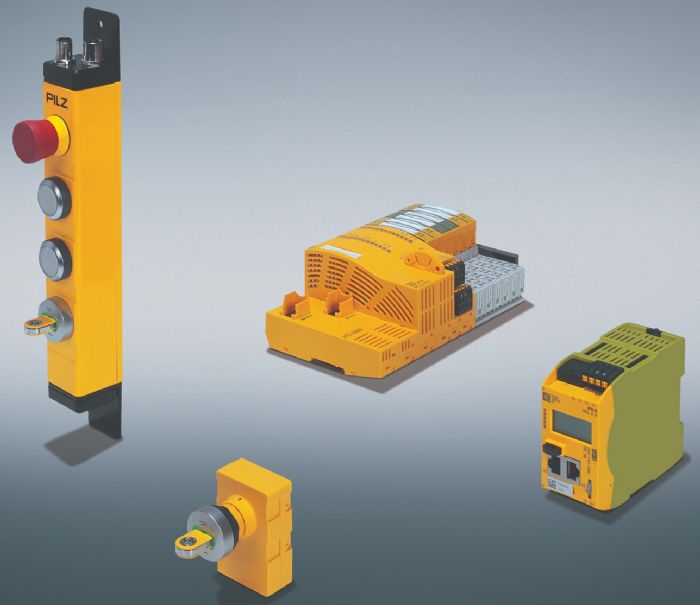

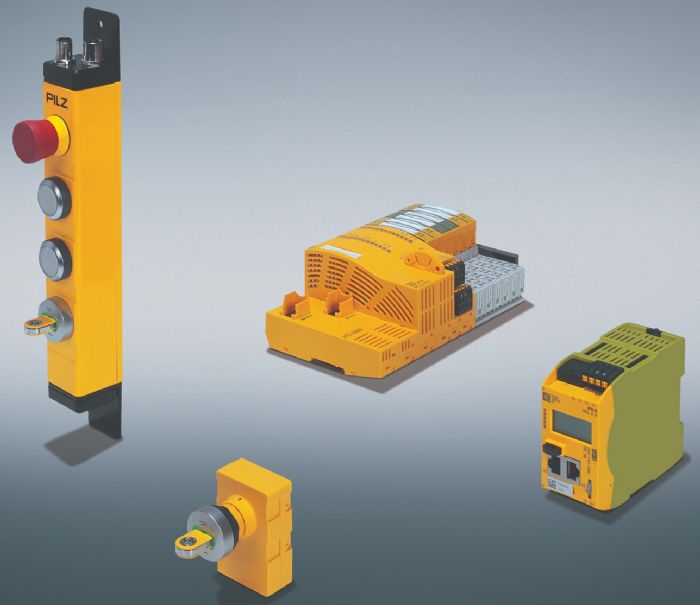

| Pilz Digital Maintenance-Safeguarding System an Efficient Alternative to Mechanical Lockout-Tagout |

| The new maintenance safeguarding “key-in-pocket” system from Pilz, Canton, MI, promises to protect metal formers from unauthorized machine restarts, allowing maintenance work to be carried out safely. The digital maintenance-safeguarding solution is based on the Pilz PITreader RFID-based access-permission system and guarantees safety and industrial security, as only authorized personnel can access the plant or machine during the maintenance process. |

|

|

|

|

|

|

|

|

|

| Fixtureworks Adds to Manual-Clamp Lineup |

| Fixtureworks

has added to its array of manual-style fixture clamps, now offering

more than 80 varieties of clamps, including, swing, thrust, side-toggle,

pneumatic, form-holding, pull and strap. The clamps, adaptable to

different industrial applications and systems, reportedly provide rapid,

secure, and precise workpiece workholding, with the product mix

including clamp accessories such as mounting brackets, adaptors, bars

and caps. In both mini and heavy-duty styles, the various clamp

configurations provide clamping forces from 2 lb. on a toggle switch to

9000 lb. on a side clamp. |

|

|

|

|

|

|

|

| In-Process Inspection Software Provides Real-Time Visibility |

|

|

|

|

| Q.Shop

in-process inspection software from QDataHub, a provider of shop-floor

data-collection software, manages shop floor paperwork and monitors

quality during manufacturing processes, reportedly streamlining

inspection and test plans (ITPs), and quality reports, and integrating

all related shop-floor documents into one system. It enables users to

digitize ITPs, work instructions, MSDS safety sheets and more. |

|

|

|

|

|

|

|

|

Cutting

Cutting Pressroom Automation

Pressroom Automation

Event

Event