Welding Workcell Tailored to Large Assemblies

February 1, 2017Comments

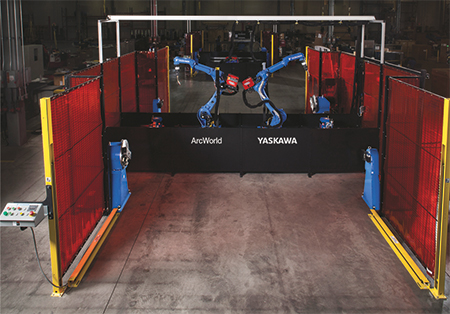

The new ArcWorld 2000 welding workcell displayed at FABTECH by Yaskawa Motoman is a modular solution designed for robotic welding of large workpieces—described as “perfect for low- to medium-volume manufacturers with a medium to high mix of parts.” Maximum part width: 5 m, with payload capacity to 6300 kg. The workcell features one or two six-axis welding robots directed by a DX200 controller with menu-driven arc-welding application software, an integrated welding package (power source, wire feeder and torch), positioner(s), operator interface and safety barriers.

The new ArcWorld 2000 welding workcell displayed at FABTECH by Yaskawa Motoman is a modular solution designed for robotic welding of large workpieces—described as “perfect for low- to medium-volume manufacturers with a medium to high mix of parts.” Maximum part width: 5 m, with payload capacity to 6300 kg. The workcell features one or two six-axis welding robots directed by a DX200 controller with menu-driven arc-welding application software, an integrated welding package (power source, wire feeder and torch), positioner(s), operator interface and safety barriers.

Users can scale the cell scales from a single-station layout to a two-robot dual-station configuration to adapt to changing production demands. Two-station layouts can be configured with a “blank station,” allowing the user to install its own equipment, and each station can have a different positioner.

Yaskawa Motoman: www.motoman.com

See also: Yaskawa America, Inc.

Technologies: Pressroom Automation, Welding and Joining

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted.Enhanced Welding Helmet Features Digital Interface, Extended...

February 12, 2025