Job-Shop-Management Software Can Pay Off Big Time

October 1, 2017Comments

The one constant for a job-shop fabricator is change. The right software can track, analyze and manage that change successfully, delivering dividends to the bottom line.

“Placing all of the data into one central program allows all areas of an inherently complex contract-manufacturing fabrication company to work together.”

That’s how Greg Ehemann, senior vice president of sales for Shoptech Software, headquartered in Hartford, CT, and a provider of E2 Shop and E2 MFG software, describes ideal fabrication-job-shop ERP software.

Ehemann should know. He started Shoptech (www.shoptech.com) in the late-1980s with his brother, and the company’s software emerged from the experiences gained in the job shop they grew up in.

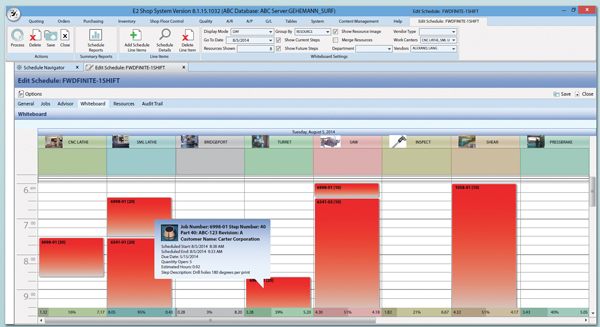

Predict the Ripple Effects of New and Adjusted Work

“Controlling the chaos brought by so much change,” Ehemann says, “means letting shop management get to the information that is going to change, and show the effect that change will have. It is essential to track change and its ripple effects.”

Assessing those ripple effects, before they manifest, is key.

“Suppose a customer calls today requesting quicker turnaround,” explains Ehemann. “A good software package can take that job, change the projected completion date, add the job to the schedule and show the consequences of the addition.”

This includes a list of all the jobs that will be rescheduled to accept the pushed-up deadline, and how that will impact materials, machine usage and a host of other variables.

“For example, software users can see all of this as well as track related conversations between the manufacturer, customer and vendors,” Ehemann says. “This allows everyone at the manufacturer to be on the same page as change occurs.”

Addresses On-Time-Shipment, Job-Profitability Concerns

In his frequent meetings with job-shop fabricators, Ehemann frequently hears the same concerns from those researching shop-management software. MetalForming asked him to elaborate on these concerns.

“Job-shop manufacturers frequently voice the need to make sure they are shipping on time,” Ehemann says. “Every company believes that they produce the best parts and products, but worry about pressures applied to their operations that may result in lower quality due to time pressures. Customers of job shops keep pushing tighter due-date schedules, sometimes dictating not only these but profit margins as well.”

Without job-shop management software that can process a wealth of information and provide detailed analysis, job-shop fabricators may not know the extent to which these pressures affect the business.

“In some cases, software can determine that a customer with such dictates may not even be profitable and not worth the work,” says Ehemann. “I’ve seen it happen, where, instead, the fabricator was able to diversify away from a large OEM, and found more profitable work. It is difficult to get out of that comfort zone of large-volume familiar customers, but the right software can lead to new customers and higher profit margins.”

“When a customer has 20 quotes sitting on the desk and has to get them out the door,” says Ehemann, “it is nice to know that one particular RFQ is from a customer that accepted only one of 100 quotes but another accepted 25 of 50. Software provides that data so you are not wasting time, and instead can prioritize your quoting process to concentrate on work you reasonably might win. This strategy saves time and money and pays off in the long run with more business through your doors.”

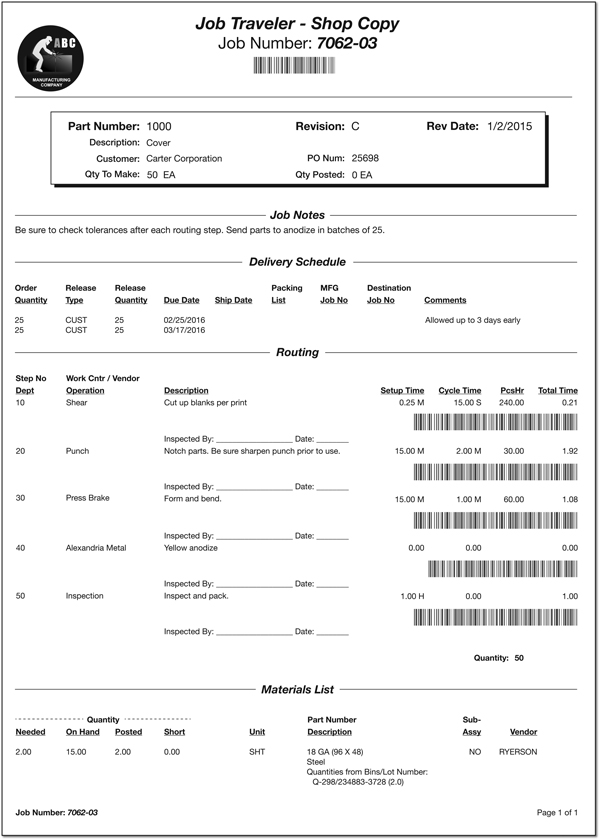

Ehemann goes on to explain how a shop management system can operate and assist fabricators from beginning to end.“The RFQs that come in can be sorted and prioritized by past winning percentage, previous profitability results by customer, etc., to make quoting as efficient as possible,” he notes. “Then, potential jobs can be dropped as what-if scenarios into the current workload. The software can determine the earliest dates of delivery, taking into account a host of variables. From there, realistic due dates can be determined—very important considering how due dates impact so many aspects of a job-shop’s operations.”