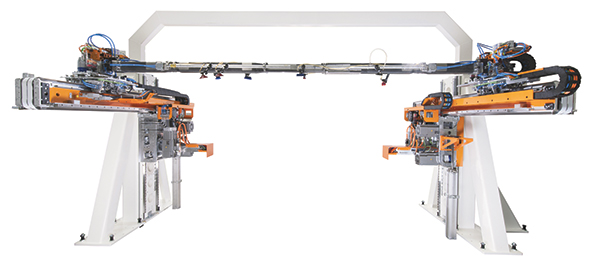

A Space-Saving Transfer Solution

The comprehensive transfer-automation concept combines a blank feeder with a fully automatic tool-change system, the CompactTransfer system, and standard robots at the end of the press line. Programming the motion curves, Strothmann used Siemens press-simulation software to determine the most efficient and safe paths. The theoretical maximum acceleration is 25 m/sec.² for the horizontal axis and 15 m/sec.² for the vertical axis. In operation, the system accelerates by 20 m/sec.² (horizontal axis) and 10 m/sec.² (vertical axis). Retrofitting the CompactTransfer system proved to be a simple and fast process for VW. It was able to exchange a complete module within a few hours by using the existing drill pattern on the press frames. In keeping with the drive for standardization and uncomplicated maintenance, only standard parts were used for the linear-motion bearings and drives. And, as specified by the customer, Strothmann installed Siemens drives for the particularly highly demanding tasks.

In comparison with articulated-arm systems, the solution therefore offers a range of advantages: the linear technology used for carrying out the complex and long transfer paths is simpler and more transparent for the operator; orientation stations are not required; and the drives are positioned where they cannot be destroyed by the dies.

Setup time also has been significantly reduced through automation. Strothmann fitted the die-change tables with front holding frames. Now, whenever the press line needs to be set up for different parts, the Compact-Transfer can simply place the crossbar in the bracket so that it is removed from the press line along with the dies. The operator can then loosen the quick-release skewers on the crossbar and exchange the tooling.

Blank loading and End of Line

The blanks are carted in front of the press line on Strothmann RoundTracks—a floor-rail system designed for transporting heavy goods. The rails are recessed to sit nearly flush with the floor, and, due to their reportedly extremely low rolling resistance (0.01 friction coefficient), RoundTrack systems require relatively little energy.

Two feeders (Strothmann SRLM-2/120 models) unload the blank trolleys at a combined 18 strokes/min. The trolleys feature lifting apparatus to mechanically adjust the stack height. Double blanks are automatically detected and discarded, and then the sheets are washed and lubricated. An indexed conveyor then transports blanks to the press as a set of four line cameras monitors their positions. A vision system analyzes the data and, based on the results, directs two centering robots to correct blank position.

At the end of the line, an out-feed conveyor carries parts a from the press line where awaiting parts-removal robots orient the parts for the operator. The operator then loads the parts into customized containers that locate them in the correct ergonomic position for unloading at VW assembly lines. MF

Article provided by Strothmann, with U.S. sales based in Marietta, GA: 770/424-4141; www.strothmann.com.View Glossary of Metalforming Terms

See also: X

Technologies: Stamping Presses