Addressing Limiting Factors for Continuous Seam Welding—Part Two

March 1, 2019Comments

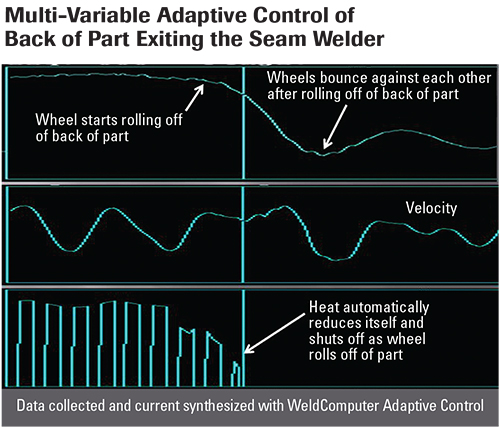

Machine capability and control capability determine how fast a production seam welding process operates. Speed increases until a limit is reached for four machine parameters: wheel velocity; current required for producing welds; cooling to keep electrodes and current-carrying conductors from getting too hot; and electrode force required to maintain material containment during the formation of each weld.

|

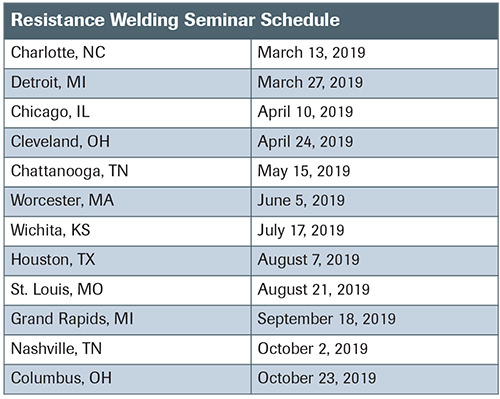

| Front end of part: Adaptive seam welding at 22.5 in./sec. |

Selecting a control with a high-enough operating-current limit, such that current is not the limiting factor in determining how fast welding can occur, ensures that the adaptive control runs the machine at maximum speed while maintaining weld-consistency standards.

This article digs deeper into what fabricators must know about machine parameters and controls for ensuring consistent continuous seam welds.

Velocity and Electrode-Force Variations

As the speed of a seam welder increases, variable loading of the part presented to the machine, motor-torque limitation, gear backlash, belt oscillation, less-than-optimum tuning of the motor-control-feedback parameters and machine mechanical resonances can cause significant instantaneous wheel-velocity fluctuations. Increasing the speed also reduces the time available to make each weld. As the weld time decreases, instantaneous velocity fluctuations increase weld variation. Velocity variations on a seam welder translate into variations in the size of the welds produced. Reducing velocity fluctuations from an existing machine could require impractical and costly engineering design changes.

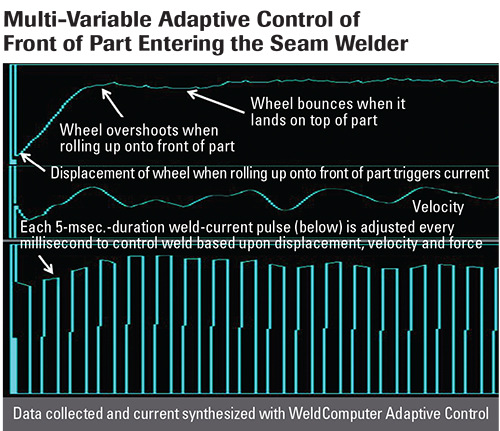

Another challenge: As the speed of a seam welder increases, so does electrode-force variation, a source of weld variation. As the seam wheels roll up onto the front of the part at high speeds, the wheels often overshoot and bounce onto the part. The momentary higher electrode force caused by the bounce can translate into an undersized weld, causing a leak. Depending on the resonant characteristics of the electrode-force system, the step of the wheels rolling up onto the part can excite a machine resonance, which could take several oscillation cycles to subside. Each of these oscillation cycles can translate into a weld that is too cold as the wheel bounces down on the part, followed by a weld that is too hot as the wheel bounces off of the part.

Just as with reducing velocity fluctuations, eliminating electrode-force fluctuations caused from exciting resonances on an existing machine could require engineering design changes and retrofits that would be impractical and cost-prohibitive to perform.

|

| Back end of part: Adaptive seam welding at 22.5 in./sec. |

Current Concerns

Increased wheel speed requires higher current and faster welds because the spot must be produced and completed before a substantial portion of the wheel surface rolls away from the site of the weld. Accurate delivery of short-duration, high-current impulses are required to control weld repeatability. Cool time between each of these weld impulses aids the formation of individual overlapping weld nuggets, and reduces the operating temperature of the seam welding wheels. Reducing the temperature of the seam welding wheels generally improves weld quality, extends the life of the electrodes and reduces machine-maintenance requirements.