Servo-Driven Turret Presses Conserve Energy, Minimize Carbon Footprint

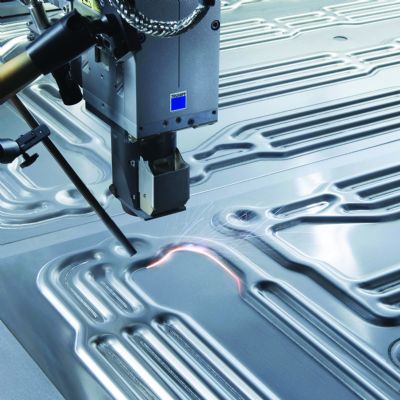

December 1, 2008Comments Amada electric servo-drive turret punch pressMetalformers looking to go green might do well to consider electric servo-drive turret punch presses as they expand their fabricating operations—presses such as the EM and AC series from Amada

America Inc., Buena Park, CA. The presses, say Amada officials, help companies achieve goals of environmentally friendly manufacturing by reducing energy consumption,eliminating the need for hydraulic fluids and pumping systems, and offering a minimal carbon footprint. All of this, with no sacrifice in punching speed and ram motion control.

America Inc., Buena Park, CA. The presses, say Amada officials, help companies achieve goals of environmentally friendly manufacturing by reducing energy consumption,eliminating the need for hydraulic fluids and pumping systems, and offering a minimal carbon footprint. All of this, with no sacrifice in punching speed and ram motion control.

Electrical consumption, compared to similar-tonnage hydraulic presses, is roughly half with servo, says Amada. And fabricators can save in excess of $1000 a year on maintenance costs by not having to replace hydraulic oil. Lastly, carbon footprint—which refers to the amount of greenhouse gases generated and discharged into the atmosphere during electricity production—can be reduced by 20 tons per year or more thanks to a switch to servo-drive machines.

Amada America Inc.: 877/262-3287; www.amada.com

See also: Amada North America, Inc

Technologies: Welding and Joining