Error-Free Automated Assembly a Money Saver

June 1, 2009 An inhouse-designed automated-staking assembly cell economically eliminates human error in producing seating components for this Tennessee automotive supplier.

|

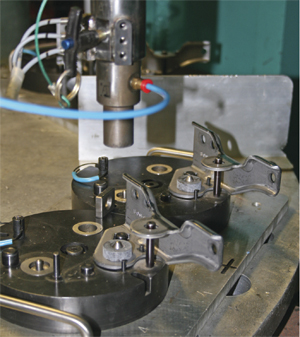

| Fixtured parts undergo staking in an

automated assembly cell at the Mount Juliet, TN, stamping and

automated-assembly operation of Orchid International. The cell,

designed and built inhouse, has eliminated human error during assembly,

according to company officials. |

Dwindling automotive volumes have forced parts suppliers to re-examine production and squeeze efficiencies out of every process. The Mount Juliet, TN, stamping and automated-assembly operation of Orchid International has accepted that challenge with gusto. Consider the custom-built staking assembly cell perfected inhouse to produce seating components for long-time automotive customer CRH (C. Rob. Hammerstein GmbH & Co., with North American headquarters in Clanton, AL). The components, incorporated into seating mechanisms at CRH, then head to a Tier One seating manufacturer that builds out complete seating modules destined for Ford F-Series vehicles, as well as the Focus, Flex, Lincoln Towncar and others.

How dependable is Orchid’s new staking assembly cell? Since it entered production in February 2008, no defective parts have been reported by the customer.

“Our efforts saved $64,000 per year in direct labor costs,” says Volz, “plus untold savings to our customer and our company by successfully eliminating every conceivable error.”

Had to be Mistake-Proof, Economical

Upon being awarded the CRH contract in 2007, Aaron Volz, manufacturing engineering manager at Orchid Mount Juliet, guided his team toward a goal of creating an assembly process with multiple lines of defense to ensure mistake-proof production.

“We began by considering what could go wrong throughout every stage of the process, and then set out to build a staking assembly cell with the necessary features to prevent these potential errors,” Volz says.

The team also sought to build a system as economically as possible, resulting in cost savings for Orchid and CRH.

“Our staking cell combines various time-proven technological tools,” Volz emphasizes. “Many components were already inhouse and were brought together to build a very robust system on a tight budget.” Components used to construct the assembly cell include a dial table, staking guns, multi-camera vision system, electropneumatic regulators, pressure switches, various sensors, conveyor system, safety cage and a 10-year-old Motoman robot resurrected from storage. The only significant purchase was the dial table, from Tri City Automation Inc., Guelph, Ontario, Canada.

|

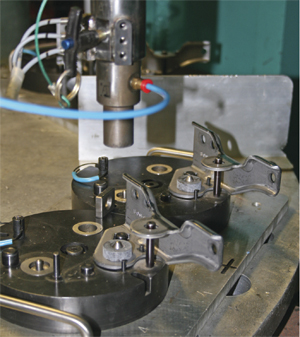

| Once the cell operator enters a part number into the computer, the staking cell’s vision system checks to verify that the correct parts are loaded, including proper orientation and presence of all necessary components. Any condition not met results in an error and the dial table will not rotate until the operator corrects that error. |

Risk of Human Error Eliminated

As the team brainstormed common failure modes that could result in a bad part reaching the customer, human factors inherent to repetitive assembly received a great deal of attention. The key to success lay in tying all quality-control features back to each individual part number, according to Volz. Once the cell operator enters a part number into the computer, the staking cell’s vision system checks to verify that the correct parts are loaded, including proper orientation and presence of all necessary components. Loading a wrong part, leaving off a part or component, mixing parts from two products, or placing the part or component on the staking fixture incorrectly will result in an error, and the dial table will not rotate until the operator corrects that error. This, says Volz, eliminates approximately 90 percent of the fallout on the backside.

Welding and Joining

Welding and Joining Welding and Joining

Welding and Joining