With procedures established for a given welding process and joint design, they then must be strictly followed during subsequent production welding. This requirement encourages the addition of automation to a GTAW operation, to ensure repeatability and traceability, and the ability to establish limits and restrict the adjustment of any variable to stay within qualified procedures.

Where Robots Make Sense

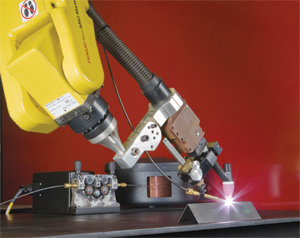

Robotic GTAW provides a number of quality-control advantages, including automated, repeatable, uniform and consistent welds, with increased productivity—particularly when considering the speed of torch repositioning between welds. Using a robotic arm provides repeatable access to welds that might otherwise be difficult to reach manually or that might require torch rotation.

Key benefits of robotic GTAW welding include:

• Repeatable, precise heat control and exact penetration to meet challenging quality standards;

• On-the-fly procedure adjustment, for automatic switching of procedures between thick and thin applications;

• Torch movement and automated control of the welding variables such as shielding-gas preflow, starting weld current, current upslope time, welding current, pulse frequency, current downslope time, crater-fill time, and gas post flow. Arc length can be automatically maintained with automatic voltage control, and bead width, penetration, and surface appearance can be tightly controlled.

• Improved welding productivity, by as much as 300 percent;

• Reduced operator training time and inspection costs, and improved weld quality; and

• The ability to save multiple weld schedules and several hundred welding programs, for easy retrieval.

Robotic GTAW is used in a range of successful applications, including:

• Thin plate: Fusing coil ends, joining corner edges of thin materials and pipe welding of exotic materials;

• Thick plate and overlay applications: heavy-wall aluminum, overlay and hardsurfacing, and narrow-groove, thick-wall sections.

• Instrument diaphragms and delicate expansion bellows.

Stainless steel, titanium, 4130 Cr-Mo, Inconel, aluminum and special-alloy steels commonly are used in these applications. The robotic GTAW process provides advantages for each of these materials. For example, aluminum is traditionally difficult to weld using the GTAW process because it tends to expand quickly and conduct heat well. Robotic GTAW helps control heat input and ensures strong, reliable welds.

Titanium has a wide continuous-service temperature range, and the highest strength-to-weight ratio of any metal. However, titanium has a high melting point and is not very resistant to corrosion during the welding process. Robotic GTAW welding can provide precise, repeatable procedures to reduce the risk of contamination.

Stainless steels have a high chromium content, which when GTA-welded manually can easily become overheated. Robotic GTAW can be introduced to avoid the appearance of an undesirable dark color on the surface of the weldment.

With heat-resistant alloys used in aerospace and nuclear applications, it’s more difficult to achieve 100-percent penetration when welding by hand. Robotic GTAW ensures the proper ratio of amperage to travel speed, resulting in a precise weld-penetration profile.

Intelligent, Robotic GTAW

|

| Robotic GTAW already is used in a range of successful applications, including fusing of coil ends, joining corner edges of thin materials, pipe welding of exotic materials, and on instrument diaphragms and delicate expansion bellows. |

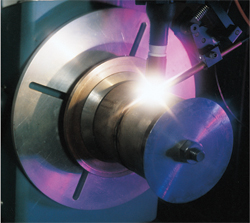

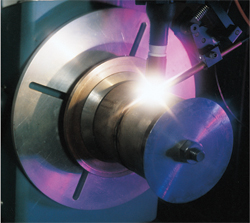

The advancement of robotic GTAW technology has spurred the development of sophisticated yet cost-effective vision systems that have substantially improved quality control, assisting with joint-location tracking and error-proofing. During procedure qualification, the operator calibrates the camera and teaches the weld path on an ideal part. This reference image is stored in the robot controller memory. On each part thereafter, the camera takes a picture before an arc is established, and the robot performs a pattern match between the reference image and the new image. The controller then calculates any required robot offsets and adjusts the entire weld path accordingly. This technology advancement is particularly suitable on thin materials where arc placement is critical.

GTAW waveforms have been created to produce a pulsed output for faster travel speeds, as well as higher amperage peaks that result in a more forceful welding arc, ideal for anodized applications. Also, GTAW of thick-to-thin materials has not als been easy for an automated system to perform. The introduction of Micro-Start technology allows for a low-amperage (2 A) starting current on thin materials that automatically transitions to a high amperage for thicker materials. New digital communication technology with a robotic system can automatically adjust the welding procedure based on torch location as it weaves from the thick material (high amperage) to thin material (low amperage), for consistent penetration control.

Torch design also has evolved dramatically. Smaller-profile torches and improvement in the design of the gas diffusers and lenses, which smooth out the shielding-gas flow and allow for greater tungsten stickout, can provide better access to tight joint configurations.

Lastly, production-monitoring software can aid in weld-data collection, and is designed to allow fabricators to analyze and improve their welding operations and processes. It also aids in meeting the requirements of ISO, Six Sigma, statistical process control (SPC), quality cost delivery (QCD) and overall equipment effectiveness (OEE) programs.

Is Robotic GTAW Right for Your Company?

There are a number of questions to ask when considering a move to robotic GTAW. They include:

• Is GTAW an integral part of the manufacturing process? Are you looking to improve productivity and implement high levels of repeatable weld quality on mild steel, stainless steel, aluminum, copper, titanium or other exotic alloys?

• Are you experiencing quality problems or competitive cost pressures from your customers? Do you have difficulty in hiring qualified GTA welders? Is your turnover of trained welders excessive? Are your labor costs increasing?

• Do you have stringent quality requirements that could be improved by automating your welding operations? Do you need improved process control for travel speed, heat input and gas coverage that an automated solution might provide?

• Are you working with a robotic GTAW integrator that is knowledgeable in the process and can provide ongoing future support for the robot system, as your needs change?

The best to determine if your company can benefit from robotic GTAW is to ask a welding-equipment supplier to review your part prints or apply a robot—in a test-laboratory environment—to your actual parts for a no-charge productivity-improvement analysis. Applications engineers will analyze your welding processes and procedures and propose improvements to provide the best return on investment and increase in productivity and quality. MF

See also: Lincoln Electric Co.

Technologies: Pressroom Automation, Welding and Joining