Innovative Conveying Solutions

June 1, 2012Comments

...help this welding-equipment manufacturer effectively move parts and scrap a from a new progressive-die mechanical press, helping to avoid bottlenecks as press speed increases by more than 300 percent compared to running production on aging hydraulic presses.

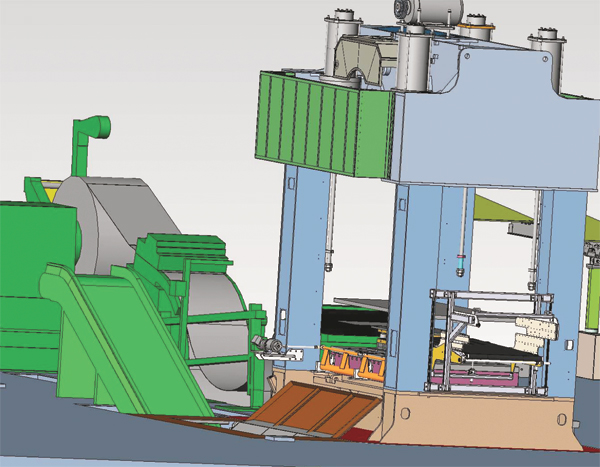

Every new-press launch faces this basic challenge: How to effectively and reliably convey parts and scrap out of the press at maximum possible press speed without inhibiting the ability to execute quick changeovers and without compromising safety. Within the confines of the sheetmetal division at Miller Electric Mfg. Co., Appleton, WI, engineers planning installation of a new 400-ton mechanical press faced this challenge head-on. With the help of stamping-system integrator TCR, Wisconsin Rapids, WI, the firm has specified and engineered a unique part- and scrap-out solution for a new press line slated to enter production in early July 2012.

The impetus for the mechanical-press project comes from the desire within the Miller Electric sheetmetal shop to add capacity while also allow the shop to satisfy from its internal customers—some 20 welding-machine assembly-lines. “Our customers are als looking for us to provide more frequent deliveries of smaller part batches. It’s all part of a longer-term lean strategy,” says Miller Electric manufacturing engineer Adam Utecht.

The goal with the new mechanical-press line is to boost press speed from a maximum of 17 strokes/min. capable when running progressive dies on the shop’s existing 440-ton hydraulic press, to as much as 60 strokes/min. on smaller bracketry with the new mechanical press, a 400-ton Aida straightside. Other than a smaller 175-ton hydraulic press also capable of running progressive dies, the rest of the stampings coming from the shop run on a set of four hand-transfer hydraulic presses.

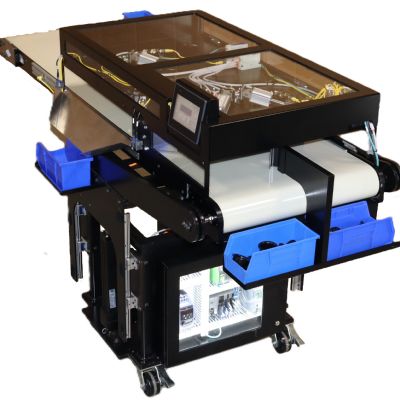

Miller Electric’s new press line features innovative scrap and part-out conveying solutions. Scrap will be funneled off the rear of the press (left) through a trap door in the floor, where a steel hinged-belt cleated conveyor awaits to move scrap a from the press and then up and out of the floor to a bin. The job of moving stamped parts out of the press will fall to a belted conveyor (right) that includes imbedded magnets in the drop area to avoid part slippage and allow rapid conveyor acceleration. To allow quick changeovers, the conveyor can slide in and out to accommodate a range of die sizes, and its tail pulley can easily (and tool-free) be raised and lowered to match die height.

Uptime and Throughput Maxed Out

While the significant boost in press speed alone is a worthy goal for any shop, Utecht and his project team also sought to minimize changeover time and maximize press uptime. Here’s where clever conveying-system design came into play.

“We knew that the move from hydraulic to mechanical, and the resulting big jump in press speed, would generate a lot more scrap at a very high rate,” says Utecht. “With the slower hydraulic presses, we have to shut down the presses for 15 min. or so a few times every shift to change scrap bins out.”

Running at a maximum of 17 strokes/min. (and maybe half that rate with manual-transfer operations), scrap bins don’t fill up all that often at Miller Electric. But once its new mechanical press gets up and running, Utecht expects the bins to fill quickly. Stopping the press to empty scrap bins is not an option.

“Also, we’re installing the line where we have 10,000 lb. of crane capacity,” Utecht says, “more than double the 4000-lb. capacity available where our two progressive-die hydraulic presses currently operate. The added crane capacity will allow us to run much larger coils of steel and eliminate a lot of coil changes and associated press downtime. By also eliminating downtime to change scrap bins, we’ll significantly optimize press uptime and throughput.”