Transfer Overhaul Keys Successful Takeover Job

February 1, 2010Comments

An abandoned servo-mechanical transfer system receives a top-to-bottom refurbishment that, along with newly engineered transfer tooling, results in a successful takeover project yielding a huge productivity boost.

Steel Parts Manufacturing, Tipton, IN, is a contract metal stamper that provides stampings and assemblies to the

Tier One and Tier Two marketplace. Early in 2009, the firm aimed to capitalize on an opportunity to bring in takeover work, as a Tier Two automotive supplier, from another stamping company in Southern Indiana. To do so, it had to make some capacity decisions to accommodate this shift in work without disrupting its customer’s workflow.

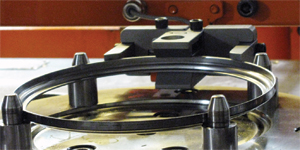

Instead, SPM decided to seek a solution on the used-equipment market, looking for a system that would suit its press and stamping process. After some searching, in March 2009 HMS managed to locate for SPM a used HMS Series 600 servo-mechanical transfer system. SPM then contracted HMS to procure the system, refurbish it, set it up at the factory to qualify it, and then run it off.

A Quick Transformation

The transformation had to occur in a very aggressive timeframe. Having brought in the dies for the parts, production operators at SPM were running multiple shifts in hand-transfer mode to keep pace with the existing production requirements. SPM sent existing tooling and station samples to HMS for evaluation and modifications in order to run in the newly automated press.Over a two-month timeframe, HMS went to work refurbishing the transfer system. Mounting attachments were reworked, guides torn apart and reworked, controls were upgraded and a fresh coat of paint applied. Once the equipment was ready, HMS and SPM engineers worked closely to create a window to commission the equipment and to support limited production runs.

Tooling Phase One

Due to price-point and timing requirements, the two companies decided that SPM should use the existing transfer-finger tooling as a starting point. Considerable modifications to the dies were required to get this process to operate in this press and transfer system. These modifications—primarily to guide mechanisms—were driven by differences between the original transfer system and the refurbished HMS system, and in the press characteristics. Press stroke went from 24 in. down to 16 in. with the Aida press, and clamp-axis travel went from 13 to 14 in. down to 8 in. with the HMS transfer system. These changes were accommodated for during a series of Internet-based design-collaboration meetings between HMS Engineering, SPM’s engineering department and the die vendor.

At install in June 2009, the transfer system and two sets of finger tooling ran off at 12 strokes/min., with abrupt movements required from the transfer automation because of the existing timing and clearance conditions. This was a huge improvement over the hand-transfer setup, and SPM’s customer visited the plant and bought in on its ability to supply the parts in a transfer mode for the long term

Video

Video