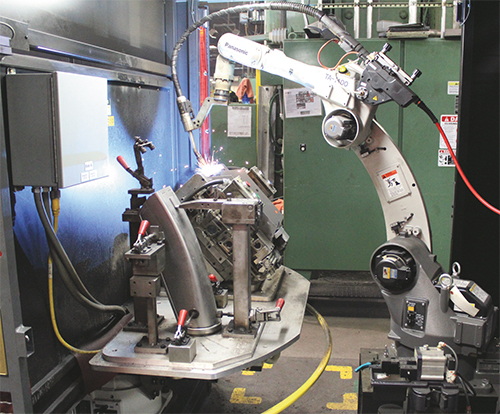

Reduced Downtime, Greater Productivity

Since implementing the new robotic-welding cells, Ariens has seen productivity increase by some 25 percent. And, the company has greatly reduced the amount of time lost to maintenance, repairs and tech calls. Says Dave Lutterman, manufacturing leader in the large-press fabrication department:

“In the past, we would weld a chute and a tractor frame in about140 sec. We now complete that same weldment in 89 sec.”

Heiting also expresses appreciation for how quickly operators can reset the robots in the event of an error recovery.

“Error recovery no longer requires a call to a technician for support,” he says. “The machines go into soft-servo mode when a reset is needed, which allows for rapid error recovery and protects the robot and fixtures from damage. And, the cells remain in the same program during the recovery process—there’s no need to go back and start from scratch. As soon as the operator clamps the fixture back up, the cell simply completes the cycle; the previous robots would not do that.”

Included with its new welding cells is the ability to program the robots offline, which allows programmers to test welding routines virtually and ensure that fixtures will work from the start, without having to make changes on the fly.

A Quality Uptick

In addition to boosting productivity, Ariens’ new robotic-weld cells have reduced or eliminated incidences of weld spatter, missing welds and short welds.

“Our older robots, some of which had 80,000-plus hr. on them,” Lutterman says, “had begun to miss some welds. We also were experiencing unacceptable amounts of weld spatter and porosity.

“Since implementing the new cells,” he continues, “we’ve improved our quality in some cases by 94 percent.”The noticeable improvement in quality means a much cleaner product, which results in less time and money spent on rework.

“In the past we would have large bins of robotically welded parts that we would have to send to a manual welding booth for rework,” Lutterman adds. “That was cut dramatically. And we don’t have weld-spatter issues—we’re not sanding chutes and frames like we used to.” MF

Article submitted by Miller Electric Mfg. Co., Appleton, WI: www.millerwelds.com

See also: Miller Electric Mfg. Co.

Technologies: Pressroom Automation, Welding and Joining