Automate the Pressroom with No Upfront Cost?

April 1, 2022Comments

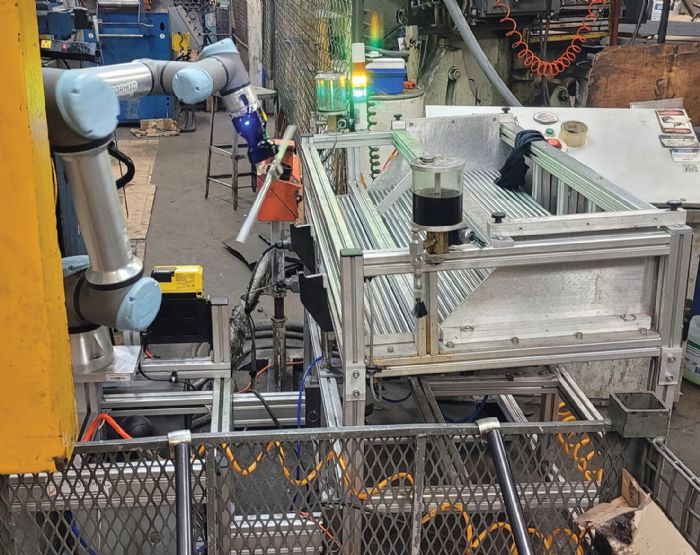

“Sign me up for that,” says Jose Figueroa, plant manager at Chicago’s Polar Manufacturing, an OEM of heavy-duty truck hardware. Polar now enjoys the benefits of two cobot-tended operations—a stamping press and a spot-welding machine—both financed by a third party to which it pays an hourly fee. Call it Robotics as a Service.

Polar Hardware Manufacturing Co., established more than 100 years ago in Chicago, IL, fabricates a broad range of door and truck body hardware—think heavy-duty cam locks and latches, truck-trailer hinges, handles, and rope rings, for example. It’s a broad product set, but Polar’s experience and stable of machines make that breadth of production possible. However, until recently the firm had no automation deployed on its plant floor, “due to cost,” says plant manager Jose Figueroa. “We simply couldn’t justify the investment needed to automate with robotics.

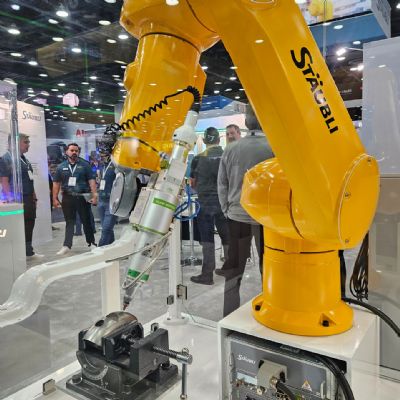

“A few years ago, our attitude changed, and we really felt that if we didn’t automate, we would not be able to remain in business,” Figueroa continues. “We have implemented lean manufacturing principles and found other ways to improve productivity, but with small returns. After looking at automation solutions at FABTECH and other tradeshows, cobot arms really looked promising, so we educated ourselves and finally decided to give it a try. We had no real consistency among our presses and operators; jobs ran at different production rates from press to press and among different operators. We felt that cobots tending the presses might improve throughput and production consistency.”

“A few years ago, our attitude changed, and we really felt that if we didn’t automate, we would not be able to remain in business,” Figueroa continues. “We have implemented lean manufacturing principles and found other ways to improve productivity, but with small returns. After looking at automation solutions at FABTECH and other tradeshows, cobot arms really looked promising, so we educated ourselves and finally decided to give it a try. We had no real consistency among our presses and operators; jobs ran at different production rates from press to press and among different operators. We felt that cobots tending the presses might improve throughput and production consistency.”

Old-School Manufacturer with a Fresh Automation Approach

Polar’s decision to take the leap into robotic automation became a reality in 2019 when Figueroa and his team surveyed the cobot landscape, impressed with the ability to, with little training, program and deploy them. However, he says, investing in automation without any prior experience still seemed daunting and difficult for company ownership to justify. Enter Formic Technologies, Inc., an automation partner that not only serves as project manager, but also purchases all of the equipment, performs any custom engineering required, takes care of all installation costs, and continues to maintain uptime and performance over the life of the system. The concept: Robotics as a Service. Formic’s customers—Polar in this case—pay an hourly rate to use the cobot setup.

“We focused on low hanging fruit,” Figueroa adds, "very-high-volume repetitive jobs fit for automated press tending.”

“We focused on low hanging fruit,” Figueroa adds, "very-high-volume repetitive jobs fit for automated press tending.”