Ignoring Conveyor PM Jeopardizes the Entire Pressroom

July 1, 2009Comments

Stampers are advised to develop a conveyor preventive-maintenance program encompassing regularly scheduled inspection and lubrication. Preplanning for service and parts saves time and money and ensures that critical maintenance items will not be subject to budget-slashing routines.

Keeping your scrap conveyors running efficiently is crucial to maintaining profitable production in any metalforming operation. Yet, scrap handling is easy to ignore. It’s not glamorous and in many cases it is not even readily visible, as many stamping plants now employ systems installed under the floor. But if a conveyor goes down, production may be hobbled, and a river of red ink can begin to flow.

In many metalforming facilities, press lines are interlocked to a main scrap conveyor, and if that main conveyor goes down the press lines automatically shut down as well. Even without interlocks, a conveyor shutdown will eventually lead to press downtime. Consider the typical JIT manufacturing scenario in the automotive industry. Should scrap backup cause a body-panel stamping operation to shut down during the morning shift, within 24 hr. the welding lines would likely go down, and then, shortly thereafter, final assembly would cease.

Additionally, excess scrap in stamping and forming operations can affect operator safety, while also putting tools, dies and other equipment at risk.

|

| Regularly scheduled PM sessions provide opportunities for the service provider to train the plant’s personnel in the essentials of conveyor maintenance. This encourages the metalformer to take ownership of its conveying equipment, and will dramatically reduce the possibility of unplanned downtime. |

Imagine Losing $26,000/Min.

The dangers described above are not just hypothetical, as one auto manufacturer with integrated stamping in its main assembly facility can attest. The manufacturer, whose main scrap conveyor crashed and stayed down for two shifts, lost all vehicle production for one shift—it typically operates at a production rate of two vehicles/min. Add to that the cost of the plant’s payroll of $26,000/min. and suddenly maintaining the health of the humble scrap conveyor becomes a critical function.

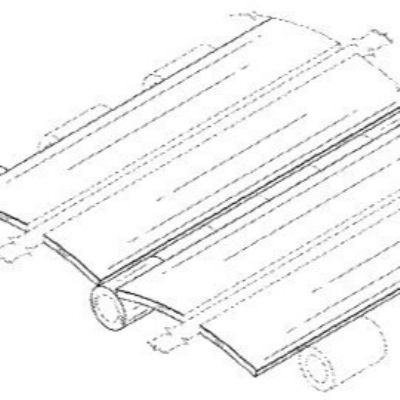

Keeping scrap conveyors running efficiently starts with conveyor design, which presents an opportunity for new facilities and a challenge for many older plants. For example, one major manufacturer (let’s call it Manufacturer A) designed and installed an extremely long main conveyor with a good layout for operations but a poor layout for maintenance. More than 1000 ft. long, the conveyor runs the entire length of the plant, but the trench in which it sits provides less than 24 in. of clearance on each side.

The plant diligently performed its housekeeping chores and kept the trench clean and clear of material. However, eventually it decided to turn housekeeping responsibilities over to an outside service, whose employees lacked the plant personnel’s understanding of the importance of keeping the conveyor trench tidy—to them it was just another hole in the floor. Over time the trench filled with debris. Along with hindering efficient operation, the debris blocked inspection of the lower rails. As the rails finally wore out, the return strand of belt fell through the frame and became jammed. The press operator, thinking the conveyor was overloaded, continued to increase its speed and eventually caused a catastrophic conveyor failure. It took the plant three weeks to clear a the debris and repair the conveyor.