The underground conveyor is a shuffle-drive unit from Mayfran International. It completely covers the underside of the cutting machine. “The Bystar comes standard with trays that capture cut parts, and operators would have had to periodically remove the parts from the trays,” says Virnig. “Using the Mayfran conveyor to capture the parts and move them to the bin avoids this labor-intensive step.”

Lights-Out Lasering

The conveyor also helps support lights-out cutting on the Bystar.

Laser-cut parts—some of which are formed in press brakes—route to one of several manual weld booths at Virnig. “Fitup tolerances with the laser-cut parts are as tight as 0.002 in.,” says Dean Virnig. “That’s a vast improvement from the 0.05-in. tolerances we were getting with plasma, and results in as much as a 10-percent decrease in weld time.”

“At the end of the night shift each Monday to Thursday evening, the operator will load material onto the storage tower and we’ll run the machine unattended from 1:00 to 5:00 a.m.,” says Virnig, “four days per week. Knowing that the conveyor’s design prevents any material from getting into its working mechanisms helps give us the confidence that there won’t be any problems. And, we make sure we schedule sheet nests for lights-out operation that won’t give us problems with part tip-up. We can’t run everything lights-out.”

Each nested sheet typically takes about an hour to cut, so after 4 hr. of lights-out cutting there will typically be four sheet skeletons stacked on the unload table for the operator to deal with. And, four sheets’ worth of parts in the bin have to be sorted. Parts then route to several manual weld booths in a 30,000-sq.-ft. production building adjacent to the fab shop.

“Here we see fitup tolerances as tight as 0.002 in.,” says Virnig. “That’s a vast improvement from the 0.05-in. tolerances we were getting with plasma, and results in as much as a 10-percent decrease in weld and assembly time.”

Welcome Laser-Cutting System Number Two

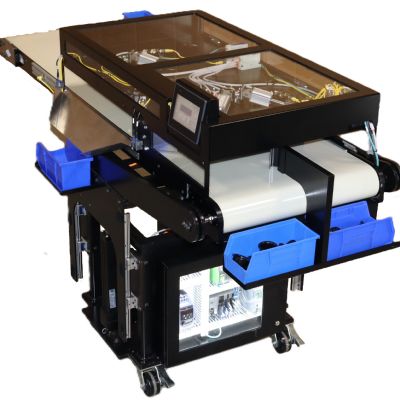

Even running lights out, Virnig finds the shop maxed out in terms of processing steel. Rather than turn again to outsourcing, he installed, just this past August, a second laser-cutting machine. This time he “upped the ante,” he says, and went with Bystronic’s state-of the-art BySprint Pro 3015 (also with a 6000-W CO2 resonator, and with a maximum sheet size of 1500 by 3000 mm).

The BySprint Pro features upgraded piercing and cutting technology, and significantly greater acceleration pierce-to-pierce, which Virnig believes will really pay off when processing its more hole-intensive sheet nests. Maximum acceleration is 12 m/sec.2 (compared to 3 m/sec.2 with the Bystar 4020), and maximum velocity is 140 m/min. (85 m/min. with the Bystar). “We’ll leave the nests with fewer pierces and that require fewer non-cutting moves to the Bystar,” Virnig says.

And yes, Virnig also equipped his newest laser-cutting machine with a Mayfran shuffle-drive conveyor underneath and an elevating conveyor to move material up and out to a bin. He again notes that “since the operator doesn’t have to empty part drawers, he’ll be able to tend to both cutting machines.” MFView Glossary of Metalforming Terms

See also: Mayfran International, Inc., Bystronic Inc.

Technologies: Pressroom Automation