Electro-Hydraulic Motion Controller

September 1, 2017Comments

...enables upgrades to railcar-wheel assembly via a simpler, streamlined system.

Machine builders that need precision hydraulic motion control, coupled with data acquisition during the machine cycle, can benefit more from a customized electro-hydraulic motion controller than from a PLC. An example are wheel-and-axle assemblies for the railcar-manufacturing industry. The process of attaching wheels and bearings to axles must meet the strict specifications of the Association of American Railroads (AAR), which requires that, in addition to making sure that precise assembly measurements are adhered to, a record is kept of the forces encountered during the pressing process.

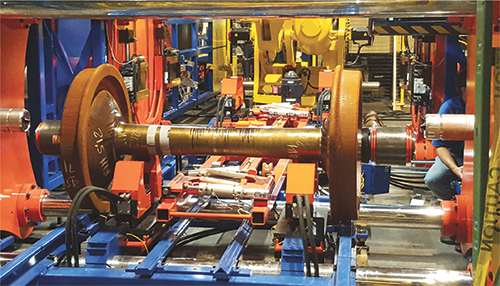

Fig. 1—After the wheels are pressed onto the axle in the Mittler Brothers press, bearings are pressed onto each end of the axle.

One supplier of assembly machines tasked with meeting these exacting requirements is Mittler Brothers Machine & Tool Co., Wright City, MO. Mittler, which makes equipment and tooling of all types, builds machines for railcar-wheel assembly in two sequential steps. First, the wheels are pressed onto the axle, one at a time. Then, bearings are pressed onto the axle, one on each end, while keeping the axle centered during the process. A completed assembly is shown in Fig. 1.

Mittler, which had produced such a machine years ago, was recently contacted by a North American railcar company to produce a new machine, which provided Mittler’s design team with the opportunity to upgrade its hydraulic controls. The previous system worked, but the wiring of its analog hydraulic control module was complex, and the programming of the PLC that controlled the overall motion was difficult. Plus, the company wanted to incorporate an automatic means of making sure that the axle is centered in the press during the bearing-assembly operation. This new approach required an upgrade to the PLC and the incorporation of a new digital electro-hydraulic motion controller.

Mittler Seeks New Motion Controller

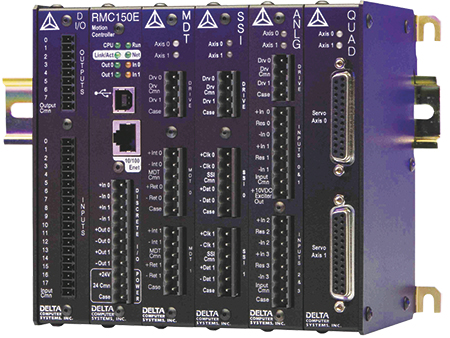

At the recommendation of Mittler’s local hydraulic distributor, John Henry Foster Co., St. Louis, MO, the Mittler Brothers team selected the RMC150, an eight-axis controller with special capabilities for precise closed-loop control of hydraulic systems (Fig. 2), from Delta Computer Systems, Inc., Battle Ground, WA. Fig. 3 shows the RMC151 in the electrical panel to the left of the 16-in. bore cylinder in the wheel press.

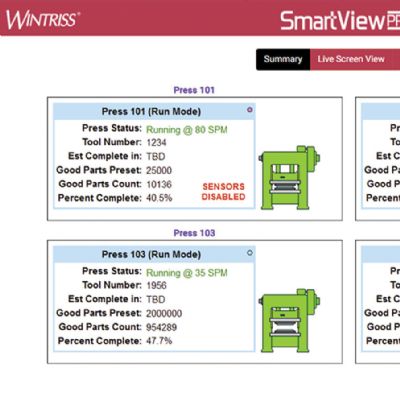

Fig. 2—The RMC151 motion controller installed in a redesigned assembly press can control and synchronize as many as eight axes simultaneously, and contains a built-in Ethernet interface.

With the new motion controller in place, the two-phase manufacturing process has been successfully automated. In the first phase of the operation, when the wheels are attached to the axle, the RMC receives inputs from position transducers mounted in the wheel-press cylinders, pressing the wheels, one at a time, onto the axle journals until precise target positions are reached. During these operations, the motion controller monitors the force exerted by computing the differential pressure between pressure sensors mounted in each wheel-press cylinder on either side of the piston. The pressures are logged and the data are retained in an information log kept for each axle.