In the world of 3D printing, anything seems possible, but engineering expertise must first ensure that what the 3D printer builds up layer by layer will fulfill its purpose. This is not easy, as the Grindaix engineers discovered. “We’re used to designing things in the traditional way, with a constant focus on the manufacturing process,” says Friedrich. “I’m not saying 3D design is alchemy, but it does require a shift in thinking.”

Therefore, Grindaix enlisted Bionic Production’s help. Founded by former employees of Laser Zentrum Nord GmbH, an application-oriented competence center for laser technology, Bionic aims to ramp up 3D-printing processes to an industrial scale. In addition to parts manufacturing, Bionic Production’s services include consulting, training, component optimization, and process and material development.

“The team of experts at Bionic Production revised and optimized our initial design to make it suitable for 3D printing,” Friedrich explains. “We learned so much from them that we’re now able to design 3D parts on our own.”

Matthias Schmidt-Lehr, head of sales at Bionic Production, knows the ins and outs of 3D printing. “Designers,” he says, “need to start by forgetting everything they’ve learned before and opening their minds to this new technology. Only in exceptional cases do you need straight lines and rectangular structures. 3D printing gives you the opportunity to create free-form surfaces, many of which would be difficult or impossible to produce using conventional CAD tools.”

Equally important is the ability to recognize the limitations of the 3D-printing process and sidestep them where possible. “In 3D printing,” says Schmidt-Lehr, “we hold the part in position on the 3D-printer platform using supports, which have to be removed once the process is finished. In many cases you can avoid using supports completely by designing the part in a certain way.”

Systematic Effort

|

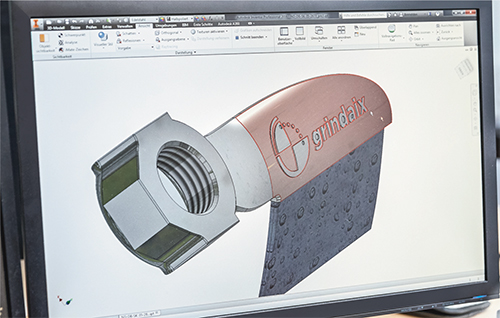

| Coolant nozzles by Grindaix feature gentle curves made possible by 3D printing. |

The first step when designing a part for 3D printing is modeling the essential aspects. For the Grindex nozzles, these included defined lubri-coolant entry and exit points, and the space required to avoid collisions with moving machine parts. After modeling the essential aspects, the designer adds as much material as necessary for the part to fulfill its purpose. “Machine cost/hr. is still a key cost driver in 3D printing,” says Schmidt-Lehr. “The smaller a part’s volume, the shorter the process time required to construct it. By leaving out any unnecessary material, we make the part lighter, often a major advantage in its own right. But even if it doesn’t matter how heavy the part, reducing the volume still makes it cheaper to produce.”

Unlike with conventional methods, in 3D printing the designer can focus purely on optimizing how the part works. In the case of Grindaix coolant nozzles, curved channels lead to a lower drop in pressure thanks to reduced flow losses. That reduces the amount of pumping power required, so the end customer benefits either from the ability to use a smaller pump or from a higher coolant-exit velocity.

Using specifications provided by Grindaix and a Trumpf TruPrint 1000 3D metal printer, Bionic Production created the perfect model of the new nozzle in a systematic process. “Software allows you to perfectly simulate many aspects of the design, such as the direction of the coolant jet,” says Schmidt-Lehr. “But the benefit of 3D printing is that it makes it so much easier to create prototypes, try them out, and then modify them as necessary.”

That enabled the team to implement every possible optimization within a reasonable timeframe and budget. This ability to tailor nozzles for customer applications delights Friedrich. “We make a huge number of different product variants,” he says. “The 3D-manufacturing technique enables us to supply the perfect nozzle to virtually every customer.”

Benefits Outweight Downsides

The new nozzle demonstrates efficiency in many ways. Optimizing the flow of coolant reduces pressure losses by as much as 20 percent, meaning that lower pressure and less energy achieves the specified coolant-exit velocity. Curved channels and optimized jet trajectory deliver the coolant precisely where needed, delivering no more and no less than is required to carry out the process in an optimum manner without causing thermal damage. This reliable and automated solution for delivering coolant eliminates factors that may have previously caused hold-ups in the manufacturing process.

Despite his enthusiasm for 3D printing, Friedrich essentially sees this particular manufacturing method as just the icing on the cake. What really gives the nozzle its unique selling point, he says, is the clean engineering process that guarantees an accurate geometric design.

“There’s a correlation between the pressure of the lubri-coolant in the line upstream from the Grindaix nozzle and the velocity with which it exits the nozzle,” says Friedrich. “We calculate the exact figures for each custom-made nozzle shape. In addition, there is a correlation between the velocity at which the water or oil exits the nozzle and the grinding speed. If you know the grinding speed, then you can achieve adaptive control of the pressure with the aid of the Grindaix nozzle flow-rate diagram. So we can tell our customers exactly what pressure they should use upstream from the nozzle to achieve a specific coolant exit velocity in the grinding process. We never had been able to achieve such tremendous precision in nozzle applications for ID cylindrical grinding.”

While pleased with the new nozzle, Friedrich does not conceal drawbacks associated with 3D printing. “Sintered parts have a rougher surface than those made from conventional metals. On the outside, at least in our case, we can correct this issue through polishing. To eliminate the roughness on the inside surfaces, which would once again lead to flow losses, we pump an abrasive fluid through the coolant nozzle at high pressure.” To achieve a tight seal, a separate process corrects the connecting thread’s roughness.

On the plus side, the 3D-printed nozzle requires two production steps versus four for the original nozzle. Friedrich contends that the high flexibility of the process significantly outweighs the disadvantages. “This nozzle would be impossible to produce without 3D printing,” he says.

Schmidt-Lehr agrees: “In many cases you don’t actually need smooth surfaces, they are just a side effect of the drilling or milling process,” he says. “But in cases where smooth surfaces are vital, rework is inevitable.”

Schmidt-Lehr finishes off by clearing up another myth: “Many companies seem to think that you can make any component using 3D printing and that it will be cheaper. Nevertheless, this method really is suitable only for a small number of parts. When you do get the right match, however, the benefits can be huge.”

50 Nozzles at Once

Though still a development project, some Grindaix nozzle customers are using the nozzles, with Friedrich expressing optimism about their future sales potential. “We’ve already progressed well beyond the prototype stage,” he says. “Together with Trumpf and Bionic Production, we have been developing concepts that will allow us to print 50 different nozzles at once. That obviously will obviously have a positive impact on manufacturing costs.”

Clearly impressed by the flexibility of 3D printing, Friedrich enthuses, “With all the know-how we’ve accumulated in this joint project, we would certainly consider producing 3D-printed parts ourselves in the future.” 3DMP

Information for this article was supplied by Trumpf, Inc., Farmington, CT; 860/255-6600, www.trumpf.com.

Industry-Related Terms: Case,

Center,

Grinding,

LASER,

Layer,

Lines,

Model,

CAD,

Abrasive,

Polishing,

Prototype,

Scale,

Scrap,

SurfaceView Glossary of Metalforming Terms

See also: TRUMPF Inc.

Technologies: