Fundamental Research into the Microstructure of AM Components Using X-ray CT

January 18, 2022Comments

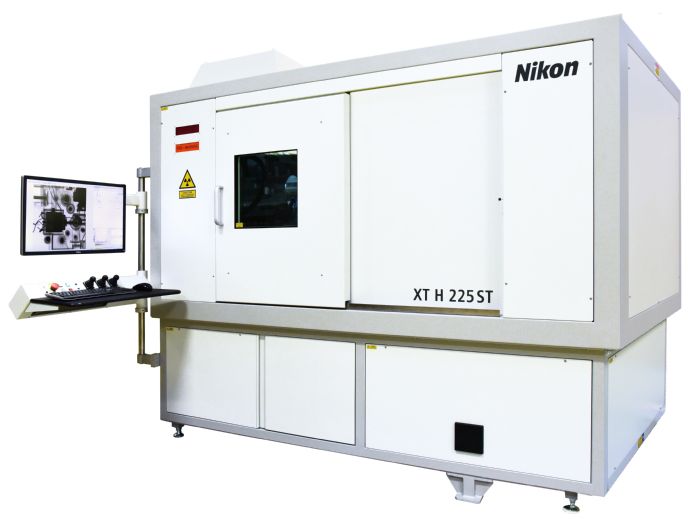

In October 2020, the University of Nebraska-Lincoln (UNL) invested

in a Nikon Metrology computed-tomography (CT) system to make X-ray CT of 3D-printed

metal parts available to academia and industry throughout the Great Plains. The Model XT H 225 ST system, housed at the university's

Nano-Engineering Research Core Facility (NERCF), helps perform fundamental

research into the effects of component geometry on overheating during metal powder-bed

additive manufacturing (AM). In a technical paper (www.sciencedirect.com/science/article/pii/S0264127521002379),

researchers propose modeling based on a novel graph-theory approach to predict

the thermal history of an AM part during the build process, and correlating the

results with the actual formation of porosity, inclusions and other flaws.

In October 2020, the University of Nebraska-Lincoln (UNL) invested

in a Nikon Metrology computed-tomography (CT) system to make X-ray CT of 3D-printed

metal parts available to academia and industry throughout the Great Plains. The Model XT H 225 ST system, housed at the university's

Nano-Engineering Research Core Facility (NERCF), helps perform fundamental

research into the effects of component geometry on overheating during metal powder-bed

additive manufacturing (AM). In a technical paper (www.sciencedirect.com/science/article/pii/S0264127521002379),

researchers propose modeling based on a novel graph-theory approach to predict

the thermal history of an AM part during the build process, and correlating the

results with the actual formation of porosity, inclusions and other flaws.

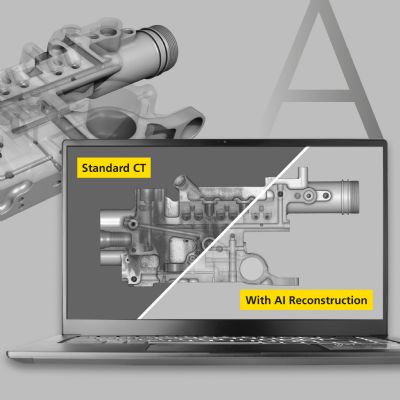

Thermal-history prediction using graph theory was shown to be impressively precise, with results being obtained in 5 min. to within 20 C throughout the build volume. And, analyzing porosity on an Inconel 718 sample, the CT system’s resolution of 15 μm/voxel was even able to determine from the circularity of a pore whether it was formed by escape gas trapped in the melt pool or by incomplete fusion of the powder.

"The equipment not only can inspect the interior of a sample without damage, but measure its dimensions as well,” says Prahalada Rao, associate professor from the UNL Mechanical and Materials Engineering department. “It allows manufacturers greater control over the quality of AM or machined parts by allowing them to see flaws that previously were expensive and difficult to find. In some fields, being able to examine the inside of components could be the difference between safety and tragedy."

Within the first four months of using the X-ray CT system, the NERCF had embarked on numerous external industry projects, including thermal modeling for a manufacturer of AM melt-pool sensors and 3D printing of oscillators for the U.S. Navy. And, discussions are ongoing within the automotive-manufacturing sector regarding testing components made using wire-arc additive manufacturing.

See also: Nikon Metrology, Inc.

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Management

ManagementMetalForming LIVE: On the Shop Floor

Wednesday, April 24, 2024

Event

Event  Management

ManagementMetalForming LIVE: On the Shop Floor

Wednesday, April 24, 2024

Event

Event