Why Sheetmetal Grain Size is Important

February 1, 2011Comments

Cut a small coupon of sheetmetal. Grind and then fine polish any of the resulting surfaces—exposed top or bottom, edge parallel to rolling direction, or edge perpendicular to the rolling direction. Etch the surface of interest and examine under a microscope to study the microstructure or metallurgical components of the material, and perhaps discover some precipitates or inclusions.

The most common observed components are grains with a

|

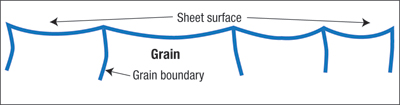

| Fig.1—Surface grain boundaries can remain high while the inner core of the grain depletes during severe stretching. This visual defect is called orange peel. |

To illustrate the fundamentals of grains and grain size, let’s consider low-carbon steel as an example. Steel is composed of atomic structures called unit cells, constructed from iron atoms. The iron cell structure is alloyed with carbon to make steel. As molten steel begins to solidify, groups of iron cells with identical cubic orientations coalesce into grains or crystals. To minimize surface area, the grains grow as spheres.

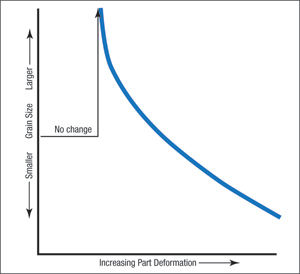

Grain size depends on composition, temperature history and other processing requirements. If a large number of grains begin to grow from the melt at about the same time, the solidified metal will have a smaller grain size. If only a few grains begin to grow, they will have more space in the melt to reach a much larger grain size. Unlike the interior of the grains, the boundaries of adjacent grains are disorganized intersections and are stronger than the interior of the grains. One of the first techniques to increase the strength of high-strength low-alloy (HSLA) steels is to generate a finer grain size with more of the stronger boundaries.

Grain size is reported as an ASTM grain-size number, n (ASTM E112 Standard Test Methods for Determination of Average Grain Size).

|

Number of grains = 2(n-1)

It’s evident why HSLA steels often have grain-size numbers ranging from 10 to 12 as one process used to increase their strength. What about low grain-size numbers? Traditional low-strength steels such as aluminum-killed draw-quality (AKDQ) steels or the newer designations of drawing steels (DS) and forming steels (FS) have grain-size numbers around 6 or 7.

Grain-size numbers of 5 and lower can create a visual surface problem called orange peel. Remember that the grain boundaries are stronger than the grain interior. When the steel is stretched to large strain levels, the grain boundaries resist deformation and allow the core of the grain to deform (Fig. 1). This obviously is not acceptable for a Class A surface, so some companies will specify a grain-size number of 6 or finer on their purchase orders.