Punching Holes with Sharp Corners

March 1, 2010Comments

Question: We’re having difficulty punching a square hole in 0.125 in. thick low carbon steel. The problem is two-fold: First, we keep getting burrs in the corners of the square opening. We increased the cutting clearance, which helps a little, but the corners still show an excessive cutting band—more than one-half of the material thickness—and the burrs come back after a short period of time. The second problem is that the corners on the punch tend to break down very rapidly, even with 12 percent per side cutting clearance. To complicate things further, our customer refuses to allow more than a 0.020-in. radius in the corners. Any suggestions you may have would be greatly appreciated.

A: Yours is a classic problem when punching square holes, especially those with sharp corners. Similar issues can also occur in square holes with corner radii. The problem is high compression in the punched corners, which results in a tighter cutting clearance in the corners compared to the straight portion of the punch profile.

Improper punch-to-die clearance is the source of many hole-punching problems. When clearances are too tight, an increase in cutting pressure is required to make the hole. This increase in pressure can chip or rapidly break down sharp corners on the punch. Excessive punch wear increases the amount of grinding that is required to sharpen the die. This can significantly reduce die life. Other problems associated with tight punch-to-die

|

| Fig. 1 |

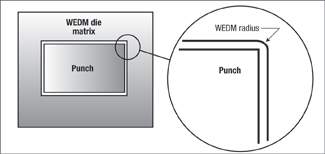

To better understand the problems with square holes, refer to Fig. 1. Notice that the die matrix has a radius in the corner. This is the result of the wire-EDM process. Even though the WEDM machine was programmed to make a square corner on the punch, a small radius was left in the corner of the die matrix due to the round wire.

The problem here is that the die clearance is too small when the punch corner is square. This produces a very tight cut in the corner that produces a cut band through almost 100 percent of the material thickness. This tight cutting condition produces large burrs and can cause the punch corner to wear and break down very rapidly.

Now let’s suppose your customer will permit a radius on the punch corners to provide a constant cutting clearance. At the same time you increase the overall total punch-to-die clearance. You might expect this to solve the problem but the problem still persists. The reason is that the punching forces acting on the workpiece surface squeeze metal into the corners, thus requiring greater cutting clearance in the corners. I suspect this is the current state of your tooling.

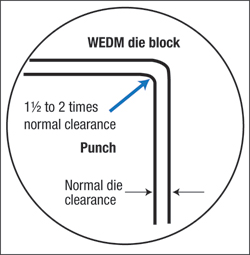

There are two possible remedies: The simplest, shown in Fig. 2, is to increase the corner radii on the punch until 11⁄2 to 2 times

the normal cutting clearance is provided in the corners only. It is important to maintain normal cutting clearance along the straight sides. When the cutting clearance is applied in this manner, the cut band around the perimeter of the square hole should be much more uniform.

Fig. 2

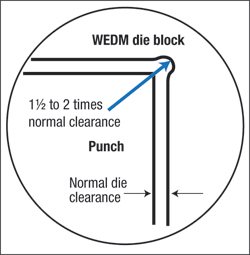

If your customer insists on a sharp corner, the solution shown in Fig. 3

should do the trick. As with the previous solution, 11⁄2 to 2 times the normal cutting clearance is required in the corner, but in this instance the clearance will be achieved by removing material from the die matrix corners rather than the punch corners. A little trial and error may be required with thin materials to balance the cutting clearance (blend) in the transition from the notch radius to the straight section of the matrix. When done correctly, you should end up with a punched hole with an equal cut band all the around, a square (sharp) corner, no burr and improved punch life.

Fig. 3

Hopefully this relieves your tight situation! MF

View Glossary of Metalforming Terms

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsThe Greening of Automotive Steel

Kate Bachman Friday, February 21, 2025

Materials

MaterialsLapham-Hickey Steel Acquires Alkar Steel and Processing

Tuesday, January 7, 2025