Unprecedented Challenges

February 26, 2020Comments

The Precision Metalforming Association rolls out its annual Automotive Parts Suppliers Conference (APSC) in April, and once again it’s a can’t-miss opportunity for suppliers to snag some time with auto-industry executives for a snapshot, and a look ahead, at key factors impacting the industry. Take a look at our article on the conference, which also provides an industry outlook, beginning on page 38. Seismic changes lie ahead, among them: electrification, development of autonomous vehicles and connectivity.

Also top of mind—as at most every manufacturing-related conference—is the skills gap. It’s affecting not only automotive manufacturing, but also the maintenance and repair industry. Consider this recent headline from the South Florida Sun Sentinel:

“The car mechanic trade is dying. Who will fix our high-tech cars?”

The article explains that, “There are roughly 750,000 auto technicians and mechanics in the country. But the U.S. Bureau of Labor Statistics concludes that the industry needs an average of 76,000 new employees in the field each year for the next decade to offset retirees and meet demands for new job openings…Working on today’s cars, which have far more electrical parts than ever before, requires veterans to reinvent themselves as lightweight electrical engineers.”

We can apply the newspaper’s headline to our industry as well—who will develop the skills and expertise needed to manufacture our high-tech cars? A recent PwC industry report, cited in our APSC article, stresses that, “Automakers and suppliers must adjust to shorter development cycles and improved recycling methods.”

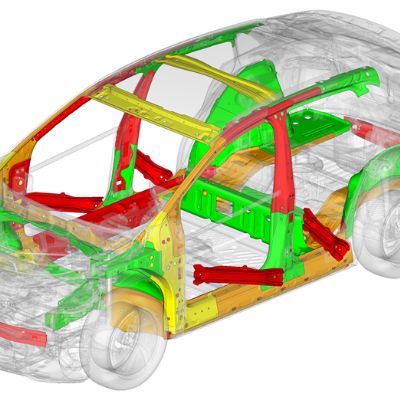

Simultaneously, stampers at every Tier level face daily challenges presented by new materials entering the auto industry—advanced high-strength steels, 5000-, 6000- and even 7000-series aluminum alloys, hot-formed steels, magnesium grades, etc. Where can we find, and then how can we nurture, the skill base, from engineering down to the plant floor, to manage these seismic changes?

Many books have hit the street lately addressing the manufacturing skills gap. I just picked up “Manufacturing Engagement—98 Proven Strategies to Attract and Retain our Industry’s Top Talent,” penned by motivational speaker and strategist Lisa Ryan. It’s all about “manufacturing the engagement” of your employees. Among her 98 strategies:

- Benchmark your top performers. Question your rock-star employees to learn what makes them tick. Ask, “What motivates you, what challenges you, how do you delegate and communicate with your team, and what shortcuts have you discovered?”

- Treat your staff better than you treat your customers. “How you take care of your employees is how they will treat your clients,” Ryan writes. “The better you make your employees look, the better they will make you look.”

- Respond quickly to staff calls and emails, within 24 hours of receiving them. “This sends a powerful signal that they are a priority.”

- Shape up or shop out disrespectful managers. “Incorporate 360-deg. reviews and keep feedback anonymous so that employees will share what they think,” Ryan writes. “When managers know that their employees have a say in whether they stay or go, they may consider their treatment of employees more carefully.”

See also: Precision Metalforming Association

Technologies: Management, Materials

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsVolkswagen Group wins Swedish Steel Prize for Press-Hardenin...

Tuesday, May 27, 2025

Materials

MaterialsThe Greening of Automotive Steel

Kate Bachman Friday, February 21, 2025

Webinar

Webinar