Brad Kuvin

Brad Kuvin Lou Kren

Lou KrenMetalForming Live on the Shop Floor 2024—Virtual Event: Automation Case Studies

February 26, 2024Comments

Back for a second year, MetalForming magazine’s popular MetalForming LIVE on the Shop Floor includes interviews with metal forming executives discussing their companies’ use of forward-thinking technology as well as videos from their shops featuring such technology in action.

Be sure to register—it’s free—for our next live, virtual event, covering automation, on April 24, 2-3:30 p.m. ET. Attendees will experience two excellent examples of leading-edge metal forming and fabricating companies leveraging transfer automation and robots to optimize efficiency and productivity. An expert-panel discussion follows that includes audience Q&A.

Automated Press Line at Clover Tool

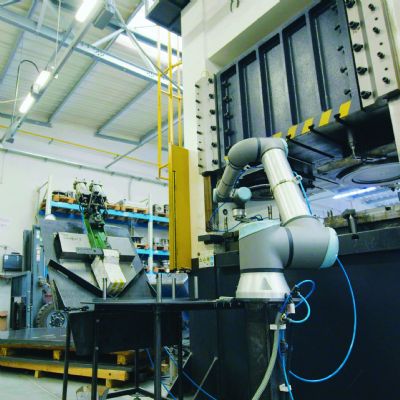

First up, Clover Tool Mfg. Ltd., a Tier-Two automotive stamper with locations in Concord and Kitchener, Ontario, Canada. The metal former currently is adding a 1200-ton, 240-in.-bed mechanical press from Eagle Press to its pressroom. Slated primarily for transfer work, the press is being outfitted with automated blank- and coil-feed equipment from Mecon Industries as well as a Linear Automation front-and rear-mount transfer system.

George Zini, president of Clover Tool Mfg. and son of its founder, will discuss the need for a large-bed press and transfer automation to handle large automotive structural parts. And he will provide a live walk-around tour of the facility.

Joining Zini are Paul Stirrett, Linear Automation vice president of sales, and Corey Chamberlain of T-Sim Solutions, to discuss best practices for proving out press-line automation concepts.

The press’ large bed will help Clover Tool meet capacity and capability needs for its high volumes of large structural stampings. And, as a contract stamper, the company also requires the flexibility inherent in this new, automated press line to handle whatever comes down the pike. After the project overview, a roundtable discussion will focus on how to optimize transfer-system performance.

You’ll find out much more on April 24, as well as in a MetalForming feature article due out in summer 2024.

Event

Event