Fabricating & Lasers—North Building, Level 3

|

|

| Building |

Level |

Hours |

| East |

Level 2 |

8:30 a.m.-4:30 p.m. |

| East |

Level 3 |

9 a.m.-5 p.m. |

| North |

Level 1 |

9 a.m.-3 p.m. |

| North |

Level 3 |

10 a.m.-6 p.m. |

| South |

Level 3 |

10 a.m.-6 p.m. |

| West |

Level 3 |

9 a.m.-5 p.m. |

Come see the latest technology in fabricating; laser- and waterjet-based machining; and displays of welding, metal treating and marking equipment. Exhibits will highlight in-process monitoring and multi-functional beam capabilities, as well as community collaboration on design, simulation, materials and quality to produce the most capable systems to support industrial manufacturing applications.

Abrasive Machining/Sawing/Finishing—North Building, Level 3

For applications that require high tolerance and precision surface finish, this pavilion has the technology you need. These technologies are particularly important to the automotive, aerospace and medical industries, all of which require a high degree of accuracy and precision. See the latest in all varieties of grinding technology, as well as sawing and cutoff machines and a variety of finishing technologies.

Additive Manufacturing—West Building, Level 3

See the continued improvements in materials and processes for additive manufacturing, including powder-bed fusion, binder jetting, material extrusion and directed energy deposition.

Controls & CAD-CAM—East Building, Levels 2 and 3

The world of custom automation and the latest software is on display in this pavilion, everything needed to optimize plant operations and cost efficiency.

At IMTS, controls, CAD/CAM and other digitally enabled tools will help define Smart Manufacturing, the Industrial Internet of Things, Industry 4.0 and other advancements in the digital enterprise. Visitors will learn how to be part of the trend to further connect islands of digital data into a fully integrated solution from design to performance to recycle and reuse.

Quality Assurance—East Building, Level 3

This is where you'll find the metrology equipment and systems to keep your processes on track and find confidence and security in the quality of your output. It's also where you'll find the equipment that will check the accuracy of your machines, an important step to protecting your investments.

Other pavilions:

- Gear Generation

- Machine Components/Cleaning/ Environmental

- Metal Removal

- Tooling & Workholding Systems.

Among the Exhibitors Showcasing Their Wares

Greenerd Press & Machine Co. will highlight its extensive hydraulic press and automation capabilities, highlighted by a large 2500-ton compression molding press it’s building as part of a seven-press order. The press features an innovative mold transfer system that the firm says will significantly improve ergonomics and safety dynamics for operators and reduce press idle time between cycles.

Greenerd Press & Machine Co. will highlight its extensive hydraulic press and automation capabilities, highlighted by a large 2500-ton compression molding press it’s building as part of a seven-press order. The press features an innovative mold transfer system that the firm says will significantly improve ergonomics and safety dynamics for operators and reduce press idle time between cycles.

Hypertherm will showcase its Omax waterjet-cutting technology, including the new OptiMax lineup promising faster and more accurate print-to-part cutting. And, Hypertherm’s Robotmaster team will demonstrate the latest version of its offline programming software for robots that pledges to take robot programming time down from hours to minutes with an intuitive programming workflow and powerfully integrated CAD/CAM functionality.

Wintriss Controls Group will demonstrate new, advanced features in its ShopFloorConnect OEE and data-collection software, including the new ShopFloorConnect PM Tracker that enables users to track important machine preventive maintenance (PM) items by run-hours or machine cycles, issues targeted alerts when an item requires PM, and tracks the maintenance work history for all machines. ShopFloorConnect 6.0 also features a new universal interactive application program interface that enables users to quickly set up two-way data sharing with any ERP or MES software.

Scotchman Industries will showcase the latest in cold saws, ironworkers and hydraulic presses, complete with ongoing, live equipment demonstrations throughout the show. Its PressPro 66 (66-ton) hydraulic workshop press has a movable cylinder (left-right) and an in-height adjustable work table. Put it to work in the shop for assembly, straightening, fabrication, quality control, maintenance, product testing, bending and forming applications.

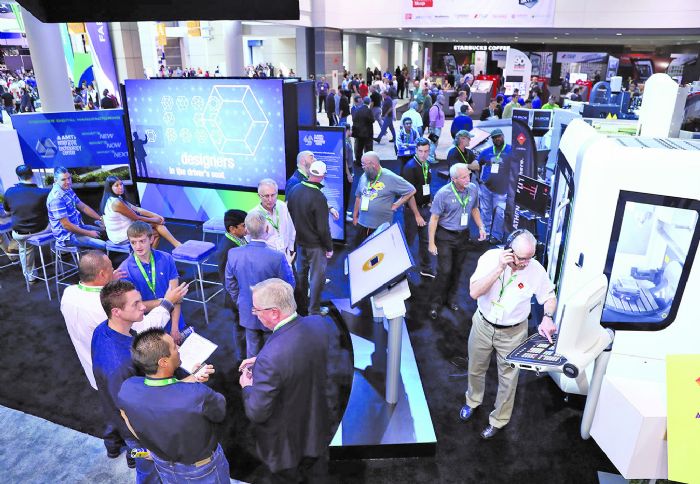

An Immersive Digital Experience

Starring in the Controls & CAD-CAM Pavilion are exhibitors such as Autodesk, Esprit and Dassault Systemes, all ready to showcase new digital twin and virtual solutions.

“We have experienced a seismic shift in the democratization of digital-manufacturing technologies designed for job-shop use to increase CNC and 3D printer productivity,” says Peter R. Eelman, chief experience officer at AMT. “These digital solutions come at a time when industry needs to harness every efficiency it can to combat labor issues and keep up with growing demand, as proven by the 30-percent year-over-year increase in U.S. manufacturing technology orders.”

“Digital twins capture data and provide critical information needed to make decisions early in the process, long before they become expensive,” adds Rob Walker, manager of technical marketing for manufacturing at Autodesk. “Digital twin technology is all-encompassing, from running simulated toolpaths with automatic collision avoidance, to checking if new capital equipment will efficiently fit within a facility.”

“You can’t run a business efficiently relying on raw emotions or gut instincts,” says Gisbert Ledvon, director of business development–machine tool at Heidenhain, which will display at IMTS its software for plant monitoring and production-data analysis. “Data really open people’s eyes. The before-and-after situation when installing a monitoring solution follows a familiar pattern. People think that they’re running at 70 percent efficiency, but data prove otherwise. When management can see the bottlenecks, it gives them confidence to execute changes.”

“Advanced digital manufacturing technology no longer is the realm of engineers and IT departments,” adds AMT’s Eelman. “During the last 4 yr., exhibitors have harnessed the increase in processing speed to create a better user experience. Powerful software is now as easy to implement as your preferred CAD-CAM program.”

Dozens of Conference Sessions Provide Unique Educational Opportunities

In addition to the vast display of manufacturing technology on the show floor, attendees also can take in more than 150 different conference sessions, most concentrated on Tuesday (65 sessions) and Wednesday (56 sessions). Among the topics on the agenda:

- Smart Technology

- Avoiding Unplanned Downtime

- Facing the Machinist Shortage: Adopting Technology to Fill the Experience Gap and Do More with Less

- Implementing IIOT Solutions

- Eliminating Scrap in Sheet Metal Stamping Production: In-Line Process Control Anchored in Smart Engineering

- The EV Revolution is Charging Up with Additive Manufacturing

- Metal AM Workflow from the Bottom of the Sea to Outer Space

- Additive for Subtractive - Design Considerations for Making AM and Machining Work Well Together

- Training Programs for Additive Production: What Companies Ask for Vs. What They Really Need

- DED Manufacturing of Large Critical Components: Pushing Boundaries of Metal Additive Manufacturing (AM)

- FDA Clearance for AM Medical Devices.

Here’s the complete conference grid.

Official IMTS 2022 hotel details and amenities.

And, please be sure to visit the rest and relaxation station in the Fabricating and Lasers pavilion, Booth #236471, and pick up your free copy of MetalForming magazine! MF

See also: Greenerd Press & Machine Co., Wintriss Controls Group LLC, Scotchman Industries, Inc., Hypertherm, Inc., Dassault Systemes

Technologies: Management

acturing, experience more than 15,000 new machining technologies, and find processes that will help solve their manufacturing challenges and improve efficiency.

acturing, experience more than 15,000 new machining technologies, and find processes that will help solve their manufacturing challenges and improve efficiency.

Greenerd Press & Machine Co. will highlight its extensive hydraulic press and automation capabilities, highlighted by a large 2500-ton compression molding press it’s building as part of a seven-press order. The press features an innovative mold transfer system that the firm says will significantly improve ergonomics and safety dynamics for operators and reduce press idle time between cycles.

Greenerd Press & Machine Co. will highlight its extensive hydraulic press and automation capabilities, highlighted by a large 2500-ton compression molding press it’s building as part of a seven-press order. The press features an innovative mold transfer system that the firm says will significantly improve ergonomics and safety dynamics for operators and reduce press idle time between cycles.

Video

Video