Don’t Answer Too Quickly

As an industry, metal formers face constant pressure to deliver products, supplies and solutions to problems as quickly as possible. This simply is the nature of our businesses. Conversely, this also can lead to many problems in our shops.

Case in point: A question from week one of the contest stated, “All energy is considered hazardous and must be locked out regardless of the servicing or maintenance task(s) being performed. True or false?”

The task being performed is a primary factor in determining when an energy source is considered hazardous. For example, during die setup a pressurized counterbalance system would be beneficial (lifting/supporting the ram). On the other hand, during machine disassembly a pressurized counterbalance system would be very dangerous. Thus, the statement is false. Only 27 of the 256 respondents answered correctly.

Another example from week three: Which of the following press machines can provide full-rated tonnage at any slide (ram) position?

- Servo-Drive Mechanical Press

- Flywheel-Drive Mechanical Press

- Hydraulic Press

- both A and C

The most popular answer was D, yet the correct answer is C. Mechanical presses, whether servo- or flywheel-drive, are rated a point just above bottom dead center. Due to mechanical advantage, slide positions above this rating point have de-rated (less) tonnage. A hydraulic press, devoid of mechanical connections, can deliver full-rated tonnage anywhere in the press stroke.

I am sure that when participants saw the correct answers to both questions, many said to themselves, “Oh yeah, I knew that. I just answered too quickly.”

That brings me back to week four of the contest. Participants were told where to find the answers, yet only 17 percent of participants answered correctly. Why?

Some probably did not want to take the time, or believed the questions to be simple enough to answer without reading the column. However, the title of the column, Urban Legends, Myths and Half-Truths, should have provided a clue that the correct answers might not be obvious.

Others may have been so focused on getting to the questions that they failed to notice that a source for the answers was provided for them along with a link to the content page.

And, perhaps a small group reasoned that “all of the answers can’t be false,” (they were) and changed one or two of their responses.

It was never the intent of the contest to observe the behavior or reasoning pattern of its participants; it became a by-product due to the surprisingly low success rate for those who participated and our desire to understand why.

Psychologists long have debated why our brains do not notice the obvious. In an experiment conducted by psychologists Christopher Chabry and Daniel Simons, people were shown a video of a basketball game and asked to count the number of passes in the game. In the middle of the video, a man in a gorilla costume passes through the crowd of players, pauses in the middle, pounds his chest and then walks off. This occurred over a period of about 9 sec, yet 50 percent of the viewers did not notice the gorilla. However, those that did not were very close or precise in reporting the number of passes. Search Simons Monkey Business Illusion on YouTube if you would like to see the video.

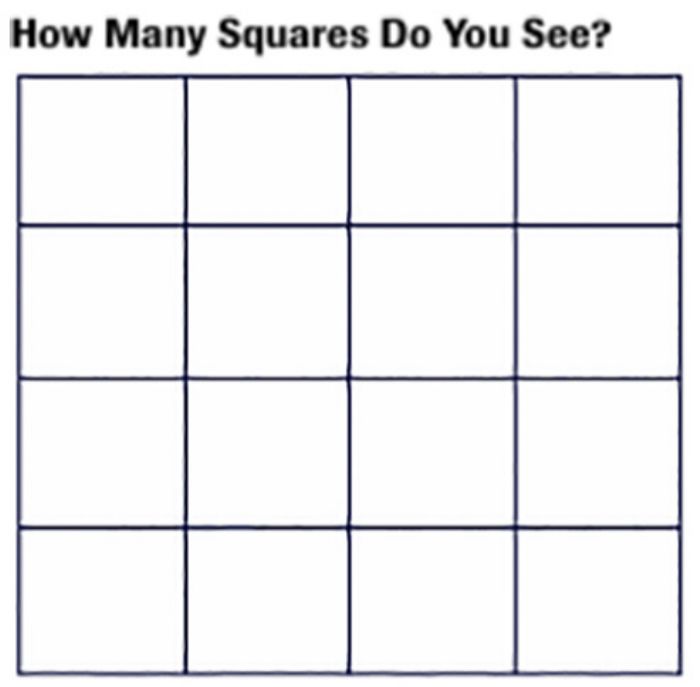

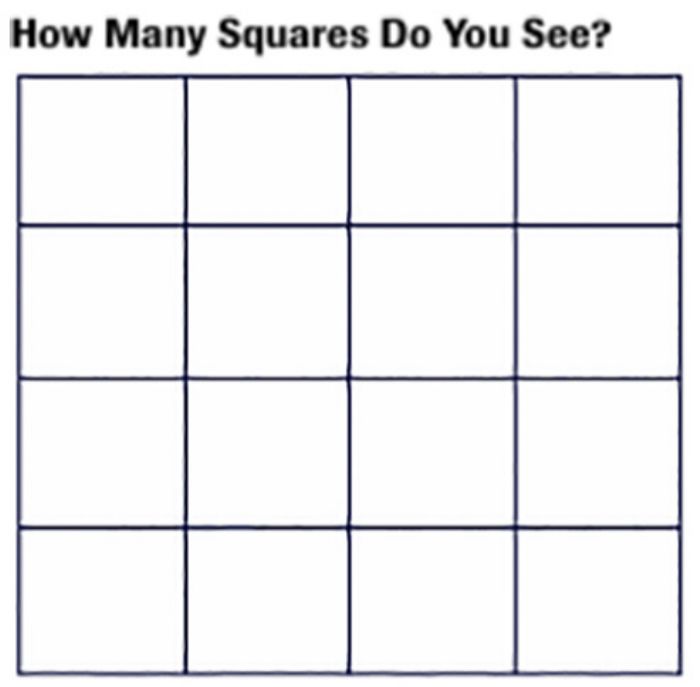

Charby and Simons concluded that when the brain focuses on one thing, it often does not notice anything else. That is why many readers struggled to find the hidden squares in the figure. They were focused on counting the ones immediately visible and did not see―or take the time to search for―the others.

Charby and Simons concluded that when the brain focuses on one thing, it often does not notice anything else. That is why many readers struggled to find the hidden squares in the figure. They were focused on counting the ones immediately visible and did not see―or take the time to search for―the others.

Finding solutions to problems in our day-to-day manufacturing operations is akin to finding the missing squares or seeing the gorilla. Metal forming professionals, tradespersons, technicians and operators routinely make decisions that affect machines costing tens of thousands, or―sometimes millions―of dollars, or tooling that costs more than the cars and houses that we own. As a result, it is imperative that we slow our thinking process and consider other alternatives before jumping to quick decisions or solutions. This is not the time to say (or hear), “Oh yeah. I knew that. I just answered too quickly.” MF

See also: Precision Metalforming Association

Technologies: Management, Tooling

Now you might be asking yourself, how does this exercise relate to metal forming?

Now you might be asking yourself, how does this exercise relate to metal forming?

Webinar

Webinar