Get to the Real Issue

Most companies considering or implementing an ERP system recognize the end goal: to improve how they do things. These companies want to eliminate dual data entry, identify bottlenecks, improve reporting, increase efficiency, reduce waste, enhance customer satisfaction, increase productivity and more. Any or all of these improvements mean change. ERP systems are often seen by management as a means to initiate change. That’s where ERP implementation runs into a brick wall.

The thought of change brings out our natural tendency to resist it. It reminds me of my early days in manufacturing as a computer programmer at an industrial water-heater manufacturer. Desktop computing was brand new. As we tackled each new function around the company, from order entry to invoicing and everything in between, we interviewed process owner about the steps in their jobs. They wanted the new computer system to work in exactly the same way as things had worked with pencil and paper. Sound familiar?

Management had hired us to improve how things were done by using computers. As we wrote custom programs to eliminate the waste we found in waiting, duplication and extra processing, we did our level-headed best to improve the process. So launching one of our new programs required double the training we anticipated. First we had to train people on how to use the computer, and second, we had to train them on how to do things the new way.

The harder we tried, the slower it proceeded. We were up against two threats:

• Resistance to computers;

• Resistance to changing how things have always been done.

As we thought about our future with the firm, we decided to attack the process before the technology, perhaps a bit selfish on our part—we didn’t want to write every program twice! The same holds true with ERP implementation—successfully achieving the vision means addressing the process before the technology. There’s more to changing any process than meets the eye…it’s dealing with the people side of change.

From Hero Management to Process-Driven Management

Dealing with the people side of change means attacking the fear of change. Our built-in resistance to change denotes a fear of what’s on the other side. Change means that the expertise our coworkers depend on us to deliver comes into question. We might not be as expert under the new system as we are under the current one. It means a shift from “hero management” to a more process-driven approach.

Most companies rely on hero management to get things done in their early years. The heroes are people who grow up with the company. They know how the system works, how to work with it and around it to get things done. As a company grows, hero management becomes less and less effective. Growing companies experience what I call the “We can’t find good people” syndrome. New people lack hero knowledge about how to get things done because processes aren’t documented.

That’s when implementing process standards helps. ISO certification becomes something that “might help us out” instead of something that would “tie our hands.” Adopting ISO or other quality-management systems means implementing repeatable, defined processes. As the firm implements processes it moves up the ladder a rung or two from hero management.

From Hero Computer Geeks to Process Solvers

At the water-heater manufacturer, it was only when we placed process change ahead of technology that we increased speed and effectiveness. We weren’t the process experts, so we asked for help—and we got more than we expected. Management:

• Called an all-employee meeting;

• Called an all-employee meeting;

• Explained a need to be more cost competitive;

• Asked every employee for ideas to save time in their jobs;

• Asked us to implement the time-saving ideas into the new computer system; and

• Announced a 10-percent bonus for the team that saved the most time that year.

A Department Time Save chart was posted in the plant and office, and every time 100 hours were saved, the company held a Friday picnic lunch, free to all employees.

This changed everything! We were no longer the “computer geeks.” Now we were the “process guys” who could help employees earn a 10-percent year-end bonus. The computers were almost secondary. Whether management knew it or not, they followed the primary steps of change management.

Change Management and ERP Implementation

Dealing with the people side of change is what change management is all about. In fact, it helps shift our thinking from “dealing with” the people side of change to leading the people side of change. It’s a process to overcome resistance, and at its best, turn that resistance into a force multiplier to embrace change and build a continuous- improvement culture.

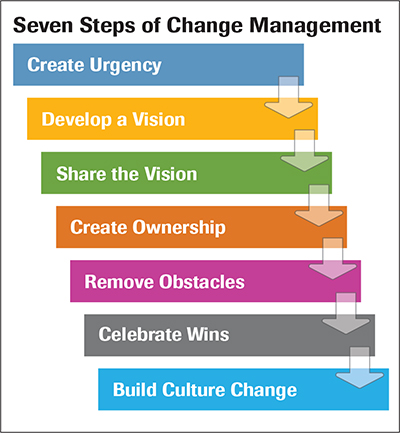

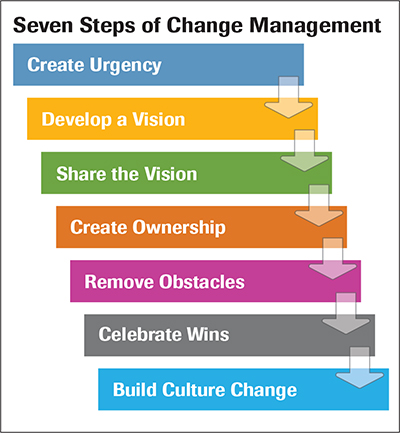

See the Seven Steps of Change Management shown above. Applying change management to an ERP-implementation project is like what the water-heater company learned the hard way:

• Create urgency—Gather all employees and share the need for change. Why are sales or profits dropping? Competitive threat? Aging products? Customers demanding better reporting? It’s important to express safety—everyone’s jobs are safe—along with urgency.

• Develop a vision—What does the company look like after the ERP is fully implemented? What is the vision of a better day? How are things done better, faster, cheaper, while increasing customer satisfaction? Build detailed 1-year and 3-year visions.

• Share the vision—Gather all employees again and share the vision. Explain why an ERP is the right thing at the right time and why you chose the particular system. This is your chance to share the story. Share the vision for how the company looks with ERP after 1 year and 3 years. Make it personal and get at the WIIFM factor —“What’s in it for me?” Pick a few examples of how an individual’s role might change. Ask for ideas to help make ERP work—the ideas will surprise you.

• Create ownership—The most successful projects, big and small, have an owner: someone who champions the project with every group, reminding everyone about the vision. The ERP go-to guy must be an employee, not a consultant or ERP-system developer. The best ERP project manager is someone who has held positions around the company, knows how things work and how to get things done, and knows what needs fixing.

• Remove obstacles—Ask employees the simple question: “What’s going to get in our way and stop us in our tracks?” Not everyone will be convinced that ERP is the best initiative to achieve the vision. However, the chance of success increases disproportionately by asking naysayers to help identify the obstacles. Focusing their attention on identifying things that can go wrong engages the naysayers to work on the project. Often, the best implementation plan is the one that attacks every obstacle head-on, leaving nothing to chance.

• Celebrate wins—Success breeds success. Create a series of readily achievable short-term targets. Whether it’s launching one department on ERP or loading all customer information into it, these aren’t easy goals, but are achievable. Like the water-heater manufacturer that offered the employees Friday picnics for every 100 hours saved, when your short-term targets are hit, celebrate the win by making sure that all employees know about it, whether they have anything to do with what drives the win or not.

• Build culture change—Quick wins represent only the beginning of what must occur to achieve long-term change. Real change runs deep. Launching one new module or department using the new ERP system is great. But launching 10 means that the process works. To reach that 10th success, keep looking for improvements.

After every ERP win, analyze what went right and what needs improving, and set goals to continue building on the momentum achieved. Keep asking for ideas around each new target—that will keep fresh ideas flowing, and helps everyone to focus on the big picture, not just on the activities in their specific areas.

Change is Good

Implementing a new ERP system provides the opportunity for company-wide change, or even bigger, enterprise-wide change that reaches beyond the company to customers and the supply chain. An ERP system is one very tangible means to embrace change. The more your organization grows comfortable with change, the more it will participate in today’s increasing speed of change, holding the potential for your company to adapt a culture of innovation.

In a culture of innovation, change doesn’t build fear, but, rather, builds anticipation. Change is what drives your employees. They become a team motivated by being part of an organization that’s always trying new things. MF

Technologies: Management

It is a common saying that technology should work for humans and not the other way around. In a similar way, a company’s enterprise resource planning (ERP) system is like a body’s central nervous system. When healthy, it provides the sensory input to management so that it can understand what is happening with customers, suppliers and employees. It helps management respond by coordinating the company’s resources to win customers, battle competitors and reduce cost, just like muscles in a body.

It is a common saying that technology should work for humans and not the other way around. In a similar way, a company’s enterprise resource planning (ERP) system is like a body’s central nervous system. When healthy, it provides the sensory input to management so that it can understand what is happening with customers, suppliers and employees. It helps management respond by coordinating the company’s resources to win customers, battle competitors and reduce cost, just like muscles in a body.  • No clear destination;

• No clear destination;

• Called an all-employee meeting;

• Called an all-employee meeting;