Precise Dispensing of Lubricants in an Airless Spray

October 27, 2020Comments

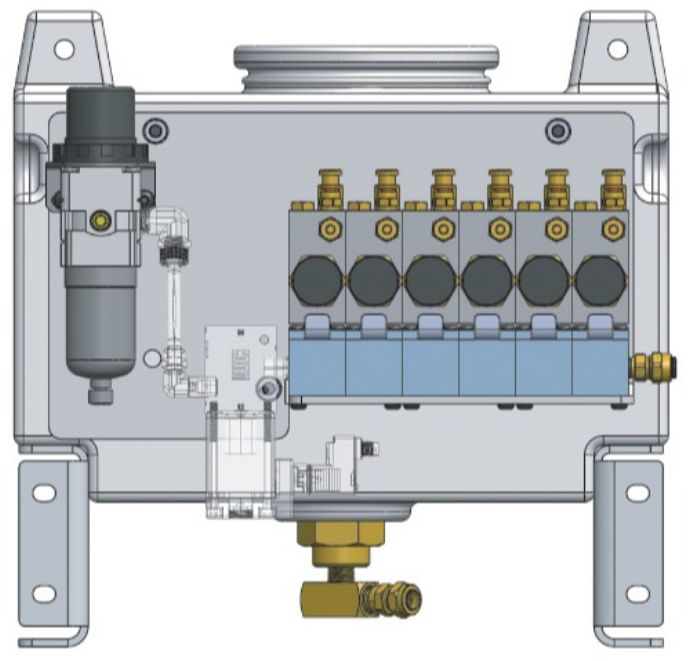

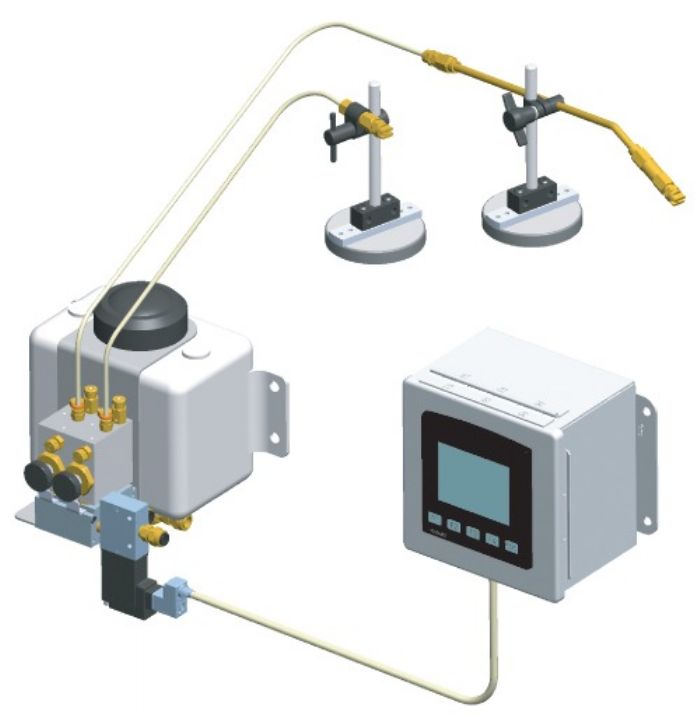

As part of the PresSpray-II family, the MicroSpray-II and the MiniSpray-II spraying systems deliver a predetermined amount of fluid in an airless spray to the work area, upon command. When an existing job needs more ejectors, simply screw another manifold into the system with four screws and then insert the new ejector. An ejector can be removed and replaced in minutes should service be required.

As part of the PresSpray-II family, the MicroSpray-II and the MiniSpray-II spraying systems deliver a predetermined amount of fluid in an airless spray to the work area, upon command. When an existing job needs more ejectors, simply screw another manifold into the system with four screws and then insert the new ejector. An ejector can be removed and replaced in minutes should service be required.

Ejectors are used in groups of up to six units in a bank. Multiple banks can be grouped for larger applications. Each ejector can be regulated as to the volume of fluid it is to dispense plus the velocity at which the fluid is dispensed.

In the application shown , a solenoid manifold is utilized to actuate individual ejectors independent of each other. Solenoids are activated from a program on the LSP electronic controller.

MicroSpray-II ejectors apply low-volume Instantaneous

airless spray. Air and fluid are separated to give a heavy droplet spray that

contacts and attaches to the part rather than fogging the surrounding area.

They deliver fluid to the work area in a fan-shaped spray pattern.

MicroSpray-II ejectors apply low-volume Instantaneous

airless spray. Air and fluid are separated to give a heavy droplet spray that

contacts and attaches to the part rather than fogging the surrounding area.

They deliver fluid to the work area in a fan-shaped spray pattern.

MiniSpray-II ejectors dispense larger volumes and heavier-viscosity fluids. The MiniSpray-II can handle many jobs, but especially those bigger jobs that demand larger volumes and heavier-viscosity fluids.

More LSP Solutions

LSP offers other airless-spray solutions, as well as roller-coater systems for coil and blanks, and low-pressure mist systems. No other lubrication-application company offers a wider variety of application options.

Webinar

Webinar