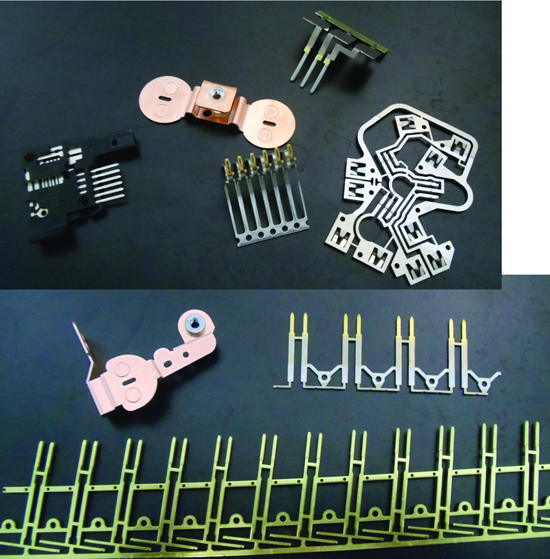

Changeover a Snap

|

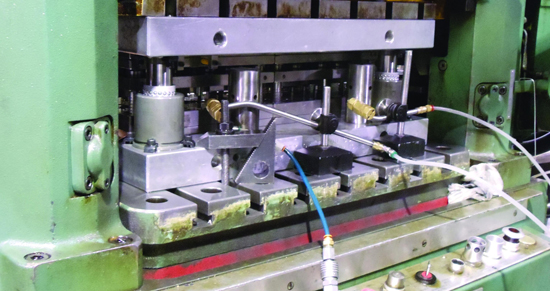

| To avoid flooding its dies with lubricant and reduce lube consumption, Sun installed the Pax 2-2 pre-pressurized lubrication system on 18 of its high-speed presses. Featured is a 2-gal. reservoir and two distribution pumps, with a maximum spray rate of 300 cycles/min. |

“Now, the new systems have a little reservoir not pressurized with air,” continues Erodenko. “The operators can fill it up with oil while the press runs, so there is no downtime due to low or no oil. The units also are easier to maintain and clean out. To change lubes, there’s a drain plug on the bottom of the reservoir that makes it quick and easy to drain, clean and refill.”

Better Control

“We’re getting much better control of where we’re applying the lubricant,” Erodenko continues, “and use several different nozzle designs based on whether we want a wide spray, pinpoint spray or something in between. While before we were flooding the tools, now we get the lube—without excess—in the right place at the right time.

“Sometimes we don’t need much lubricant at the front half of a die,” Erodenko adds, “while at the forming area you may need more lubricant.”

On some presses, Erodenko wired the system controls into a cam system on the press. In other cases, they’re wired to SmartPac units (on Bruderer presses), “so that we can set them up to spray after so many counts at a certain angle on the press,” he says. On units not wired directly to the press, Erodenko installed optional timers to set the time between sprays.

A benefit to using the timers rather than directly wiring the units to the press controls: “We can easily pick the system up and move it—pumps and nozzles—to a press that we have not yet retrofitted with the Pax system,” Erodenko adds.

Erodenko also notes the improvement in the shop environment—no more smoke or mist in the air. And, the distribution pump is adjustable, “so we can cut down on the amount of oil sprayed each cycle and the rate at which we spray—once every 10 press strokes, 50 strokes or 100 strokes,” he adds.

Custom Lubrication Application

…pays off more than just by reducing consumption and eliminating oil cleanup. “In some cases, it allows us to perform more work in the dies, streamlining process design for stamping complex parts,” Erodenko says. “With more control over lubrication—where and when—we avoid a lot of headaches and redesign time to make something work.”

|

| Each lubrication system includes a pair of piston-style nozzles suitable for spraying light vanishing oil as well as heavy-duty oil. Here, spray nozzles, mounted to magnetic bases, apply lubricant directly onto punches from the side of a die installed on a Bruderer 30-ton high-speed press. |

“On one of our particularly challenging tools, used to stamp the lead frame for telecommunications connectors at 300 strokes/min., we had been spraying the oil directly into the tool from the side, our common practice. The tool stamps very thin material (0.007 in.) and features extremely tight tolerances on the punch-die clearance (5 percent). We were pulling slugs and experiencing misfeeds.

“We moved the spray nozzles to the bottom side of the strip,” Erodenko continues, “to only lubricate the bottom of the strip. This prevented oil from saturating the punches and sucking the slugs up out of the die. This job does not run often enough to justify spending a lot of time and money on engineering, so this is a perfect example of how the flexibility and precision of the lube system pays off.” MFView Glossary of Metalforming Terms

Technologies: Lubrication