Why Automated Deburring Works in Fabrication

March 30, 2023Comments

Need quicker throughput with fewer rejects—and safer employees doing more rewarding work? Then automated deburring might be right for you.

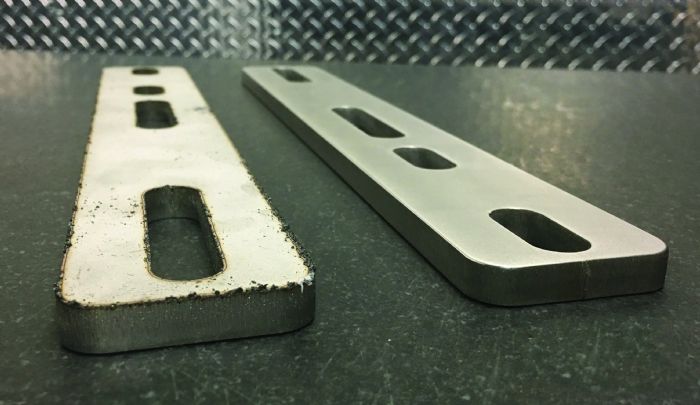

In fabricating operations, where sheet metal parts off of cutting, bending and punching machines often route to assembly, painting and other operations, clean edges are a must. This is crucial to aid in fitup, downstream processing and safe handling. Automated deburring offers big gains here, providing consistent performance, reducing bottlenecks and freeing employees from the dangers and monotony of hand grinding to focus on more value-added tasks.

So says Denis Weinfurtner, North American marketing manager for Arku Inc., with U.S. headquarters in Cincinnati, OH. In an interview with MetalForming, he outlines the advantages of automated deburring in fabricating operations and provides an update on technology developments.

“Grinding fabricated parts and components removes slag or burrs, or rounds out edges to increase handling safety, provide better fitup for assembly, and enable improved paint adhesion,” Weinfurtner offers, commenting on the importance of such deburring.

Addresses Labor Scarcity, Manual-Grinding Safety Issues

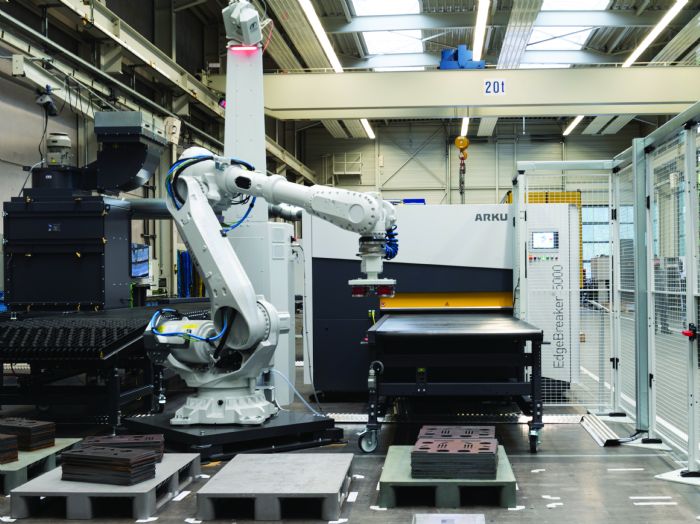

The recent pandemic aggravated an already scarce labor pool and brought new life to automation efforts on the part of manufacturers, with the labor-intensive process of deburring an ideal candidate, according to Weinfurtner.

“Many fabricating operations employ people solely to hand-grind parts after laser, plasma, oxyfuel cutting or punching,” he says. “Perhaps three to four employees, maybe across two shifts, spend their workday at a bench with a grinder and a vice. Automation in this area provides an ideal solution. At the push of a button, a machine provides safe, secure and consistent high-quality deburring results.”

Manual grinding subjects employees not only to a monotonous task, but also to risk of repetitive-motion injuries, cuts from unfinished-part handling and the breathing in of grinding-abrasive and metal dust, Weinfurtner explains.

“On top of all of this, manual grinding is time-consuming and will not provide consistent high-quality products,” he says. “You can have the best hand grinders in the world standing there for 8 hr., but they’ll cut into one part a little deeper, or grind too light on another, or round off an edge not quite perfectly. Sometimes, personnel can forget to grind a particular part feature.”

“On top of all of this, manual grinding is time-consuming and will not provide consistent high-quality products,” he says. “You can have the best hand grinders in the world standing there for 8 hr., but they’ll cut into one part a little deeper, or grind too light on another, or round off an edge not quite perfectly. Sometimes, personnel can forget to grind a particular part feature.”

Grinding creates dust, from the abrasive and the workpiece, often a significant health hazard in manual grinding. Dust-collection apparatus in such operations may not provide adequate particulate removal. Automated deburring units, according to Weinfurtner, can be outfitted to collect any dust created by the process.

As for consumable use, “a deburring machine is no different than an angle grinder, where the disc must be changed to keep up performance,” Weinfurtner says. “To maintain productivity, look for the ability to rapidly change consumables. Spending a couple of hours or even half of the workday on consumable changeout should be unacceptable.”

As for consumable use, “a deburring machine is no different than an angle grinder, where the disc must be changed to keep up performance,” Weinfurtner says. “To maintain productivity, look for the ability to rapidly change consumables. Spending a couple of hours or even half of the workday on consumable changeout should be unacceptable.”