High-Energy Nozzle Enables Spee3d Printing of Hard-Phase Materials

June 23, 2022Comments

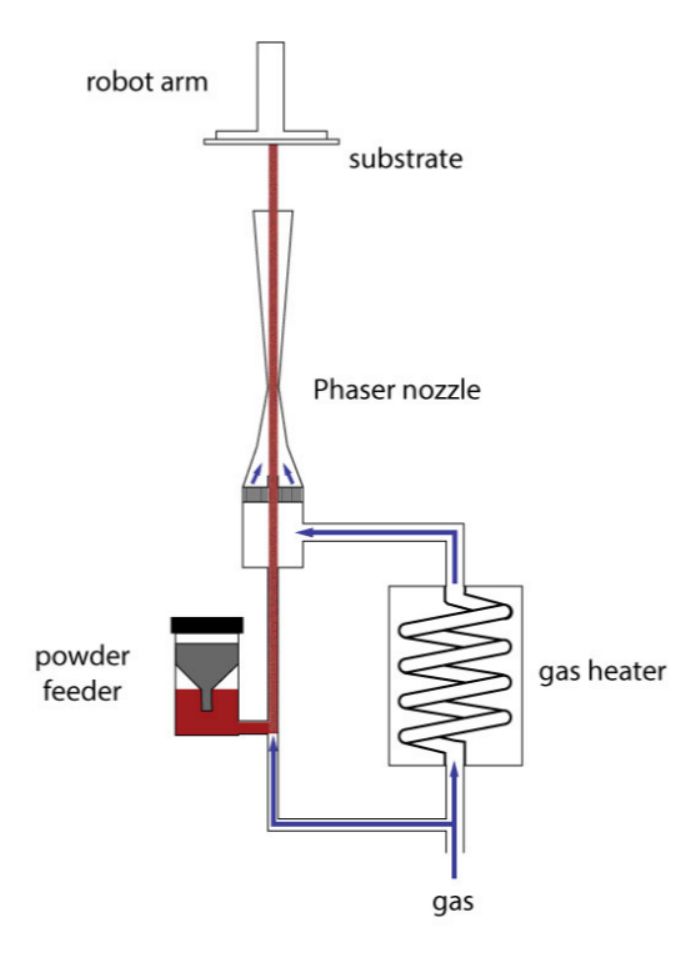

Spee3d has introduced the Phaser, a high-energy nozzle designed to work on Spee3d additive manufacturing machines with a wider range of hard-phase materials including stainless steel, titanium, high-strength aluminum and nickel-based carbides. The new nozzle allows for printing of materials that withstand severe conditions such as high stress, immense shock loads and abrasive environments.

Spee3d has introduced the Phaser, a high-energy nozzle designed to work on Spee3d additive manufacturing machines with a wider range of hard-phase materials including stainless steel, titanium, high-strength aluminum and nickel-based carbides. The new nozzle allows for printing of materials that withstand severe conditions such as high stress, immense shock loads and abrasive environments.

The high particle velocity achieved with the Phaser nozzle means more deformation of the particles during the deposition process, which allows use of these harder, tougher materials, according to company officials. Users can print these materials with either compressed air or nitrogen. Using compressed air, the Phaser nozzle reportedly deposits material four times faster than the speed of sound at temperatures to 800 C.

Besides the hard-phase materials, Spee3d machines also print standard copper as well as aluminum-bronze and other aluminum materials.

See also: SPEE3D

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Stamping Presses

Stamping PressesFagor Arrasate Begins Expansion of Its Mondragón, Spain Plan...

Friday, July 11, 2025

Fagor Arrasate Begins Expansion of Its Mondragón, Spain Plan...

Friday, July 11, 2025

Stamping Presses

Stamping PressesFagor Arrasate Begins Expansion of Its Mondragón, Spain Plan...

Friday, July 11, 2025

Software

SoftwareAccelerate Sheet Metal Stamping with Dynaform: A Complete Vi...

Friday, July 11, 2025