The Retrofit Options

This seemingly dire situation, however, is coming to an end, as suppliers get a handle on how to meet the challenges posed by forming AHSS sheet. They’re developing the science needed to overcome the challenges posed, as the “norm” goes from stamping 50-ksi steel to dealing with steels with yield strengths of 100 ksi or more. Suppliers are using FEA and other tools to develop new solutions, which Ward says typically fall into one of two categories.

“We see stampers looking either at total coil-line replacement in order to solve reliability issues when stamping AHSS, or just retrofitting the straightener of an existing line,” he says. Total coil-line replacement, including equipment for coil containment and threading, requires an entirely different business case for justification than does a straightener retrofit.

“There’s a lot more stored energy in AHSS coils,” stresses Ward. “In addition to the straightener, stampers must consider the capabilities of the holddowns and holdups, as well as the threading-drive systems, end-wheel systems and the braking system.”

However, in many cases, say Ward and Grant, just replacing the top half of the straightener suffices, to equip an existing coil-feed line to reliably feed AHSS. This includes a new head with the structural design and component content able to deliver the force needed for the application. Using the aforementioned software utilities, the stamper can be assured that the retrofitted straightener will be able to sufficiently backbend the material and apply the required roll-depth penetration. And, there’s assurance that the machine will have the required rigidity and structural integrity.

For example, Ward describes use of such a utility to prove-out the capabilities of a straightener for flattening ¼-in. 90-ksi-yield steel fed from 48-in.-wide coils. The software utility predicted for the customer that the application required roll force of 38,000 lb. (rated force of the machine was 60,000 lb.), pinch-roll gear torque of 31,400 in.-lb. (compared to a rated torque of 45,100 in.-lb.) and straightener-roll torque of 21,200 in.-lb. (compared to a rated torque of 31,500 in.-lb.)

Smaller Rolls, Tighter Spacing

Changing out components in the straightener often involves use of smaller-diameter straightening rolls than those typically specified for shaping mild steels, and use of tighter center distances to improve force transfer to the material. The gearing typically is upgraded to handle the increased forces and torque.

“In one recent retrofit project,” says Grant, “we upgraded a 1995-vintage straightener for feeding AHSS into a progressive die. The requirement was to feed 100,000-psi material from 60-in.-wide coil. Using our software tools and FEA, we were able to illustrate for the customer that the new support bridges designed for the straightener would provide sufficient structural support for the new straightening rolls. We also proved out, using simulation software, the new gearing system designed for the application.”

“We often see the need to increase roll pressure by two or three times when upgrading from mild steel to AHSS,” adds Ward. “This requires upgrades to many straightener components, including the bearings, roll journal, roll supports and the machine structure, including the weldments. Still, we often can cost-effectively meet the needs of the stamper by retrofitting the straightener for one-third or less of the total cost to replace an entire feed line. And, in many cases the stamper can pay for the retrofit from its maintenance budget rather than making a big-ticket purchase from its capital-equipment budget.”

So, what should stampers look for, and ask for, when approaching equipment providers for help upgrading their operations to handle AHSS and other high-strength materials?

“Ask for the data,” says Grant. “Do your homework, and seek to understand the science behind the technology being proposed. Study the FEA analyses to understand exactly how the machine will respond when it’s required to impart the high torque and forces needed to shape high-strength materials. Look, for example, at the roll-displacement vs. stress-analysis data. This will ensure that the machine has been properly designed to handle the stresses. Simply adding mass to the machine oftentimes proves insufficient. The added mass has to be located in the right locations on the structure to yield the required results.”

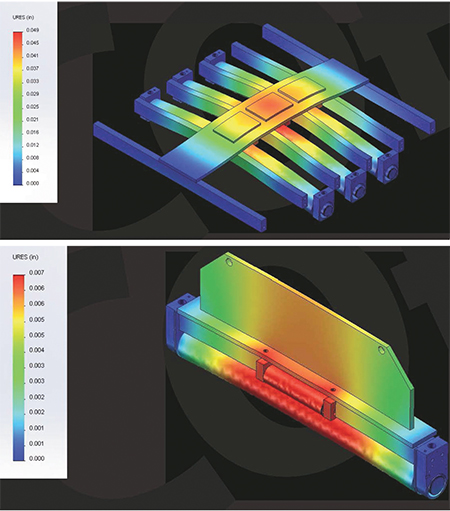

Simulation of Deflection Under Load

For example, using the tools that Coe has developed can clearly depict deflection under load of an older machine vs. that of an upgraded machine. “We might see 0.049 in. of deflection under load when trying to run AHSS in an older straightener,” says Ward. “A new machine, meanwhile, will have a bridge that deflects only 0.007 in. We can illustrate for the stamper, in simulation, that and other key performance enhancements made possible by upgrading the straightener to handle the increased loading from feeding AHSS. As a rule of thumb, we must keep roll deflection to less than 5 percent of material thickness across the width of the material. Any more than that and the straightener will start to induce edge wave in the material.”

Other utilities illustrate for the stamper the required straightener-roll settings for a given material type and coil width, and can specify threading-drive size, holddown force, drag-brake tension requirements and more.

“Tough times require new tools,” Grant says, summarizing his thoughts on the new challenges stampers face due to the onslaught of higher-strength materials. “New software tools allow suppliers to simulate for customers how upgraded equipment, designed to handle these new materials, will perform on the shop floor before equipment is purchased. And we can show them how changes in process variables will affect the outcome.

These often are unique machines we’re developing,” Grant concludes. “There’s nothing off-the-shelf.” MF

View Glossary of Metalforming Terms

See also: Coe Press Equipment Corporation

Technologies: Coil and Sheet Handling, Materials

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Coil and Sheet Handling

Coil and Sheet HandlingDallas Industries Delivers Feed Line to Precision Tool & Sta...

October 17, 2024