Setup Automation and Redundant Controls

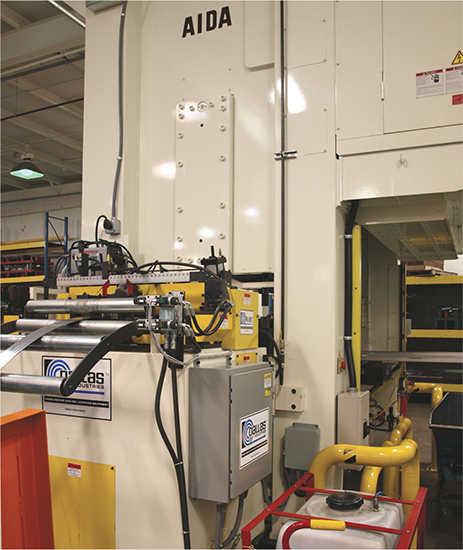

In addition to coil-line robustness, setup automation scored high on the ATD wish list when the firm went shopping for a feed-line partner for its servo press.

|

| Noting that the feeder on its 600-ton press line has had some overheating issues when dealing with higher strength steels, ATD’s Bennett says that the new line has the right gear ratio and motor capacity (20-hp motor with AC variable-frequency drive) to handle heavy-gauge high-strength work. |

“We not only wanted to eliminate the chance for setup errors,” Bennett says, “but felt that coil-line setup automation would greatly enhance our ability to accomplish quick changeovers.”

Long a focus at AT&D, setup-time reduction on its presses moved further up the priority list in mid-2013 when the firm conducted a thorough and shop-wide lean event. Feed-line changeover clearly offered opportunities for improvement. Among the automation features built into the new Dallas line, all-told allowing the firm to accomplish job setups in less than 2 min., is adjustment of feed passline height, feeder entry guide-roll width, straightener rollers, and straightener entry guide-roll width.

On the reel, Dallas supplied a keeperless coil-guide device that automatically adjusts to center the coil throughout the system and contain the coil throughout the run. Outside coil-guide rolls automatically pivot open for coil loading. A threader table with telescoping peeler blade supports the leading coil edge for hands-free thread-up, and a proportional valve controls brake pressure and provides automatic back-tension adjustment as coil weight diminishes during a run.

During the changeover-time-reduction lean event, ATD also charted how often its press operators had to move from one end of the coil line to the other during setups, and sought to save steps.

“That led us to invest in two complete and independent line-control stations, one at each end of the coil line,” adds Bennett. He’s certain that the ability to adjust settings—during setup of new jobs or to tweak parameters of existing jobs to deal with material inconsistencies—will return the investment by saving operator steps and making the process more efficient.

“We think, after talking to our operators, that the redundant line controls reduce setup time by at least 5 min. per setup,” Bennett says. “Thanks in large part to the automated features of our new press line, coil-line changeovers that might take as long as 15-20 min. now occur in 2 min. or less.”

An Eye Toward the Future

The feed line handles a maximum coil weight to 20,000 lb. and coil width to 30 in. Its drive train permits feeding of 24-in.-wide ¼-in.-thick steel. Pinch rolls measure 5.25-in. dia., while its seven straightening rolls are 3.5-in. dia. and the two feed rolls are 6-in. dia. Payout speed ranges from 20 to 80 ft./min.

Bennett and his team also talked, when evaluating the specifications for its new press line, about the company’s ability to meet future demands. These include the growing use of higher-strength steels and even advanced high-strength steels such as dual-phase alloys. That led to working with Dallas to ensure line robustness, including specifying a seven-roll straightener—compared to the five-roll straightener the firm employs at its 600-ton press.

“That 600-ton press line also has a feed line with an oversized motor,” adds Bennett, “yet we’ve had some overheating issues there. So we made sure this new line has the right gear ratio and motor capacity (20-hp motor with AC variable-frequency drive) to handle heavy-gauge high-strength work.”

AT&D already has seen benefits from the servo-press line that have enhanced its competitiveness in the market. For example, Bennett cites a job where the press performs multiple hits in one die station at the bottom of the stroke, with just a 1-mm rise in the ram between hits.

“In this case we’re effectively warm-forming the part,” he says, “which allows us to eliminate preform die stations. That operation is supported by the seamless and flawless integration of the feed-line controls with the press controls. In the end, we eliminate a die station so that the die is smaller, less complex and less expensive, improving our competitiveness.”

Bennett also points out the laser-based loop control feature provided with the feed line, with synchronized payout at feed rate. And, he expresses appreciation for the Dallas Profile Select feed programming function that automatically matches the speed of the feed advance to the available feed window and press-speed requirement, which can be tricky when synchronizing with the action of the servo press.

“This technology allows us to minimize movement in the loop, so that it remains consistent,” Bennett adds. “We feel this helps in consistently delivering straight, flat material to the press.”

Having Operators’ Backs

Also noted when we took a look at the new coil line was a pair of Hypertherm plasma-arc-cutting (PAC) machines docked to the line, to allow operators to trim the leading edges of coils as needed.

“This relatively minor investment means that the press operator need not take the time to leave the press to locate a cutting machine and move it over to the press so he can trim the coils,” says Bennett. He notes that ATD plans to eventually add PAC equipment to all of its press lines.

“We’re listening to what the operators are telling us,” Bennett continues, “addressing their needs and letting them know that we’re committed to making their jobs easier and making them more productive and efficient. It’s all about productivity.”

Bennett describes the firm’s production schedules as becoming “more erratic day by day, requiring more frequent setups. If we’re not prepared to do that in an efficient manner, we’d be costing ourselves money. Customers won’t pay for setups, only for press run time. Everything else is added costs we must absorb, so we’re working to reduce those.” MFIndustry-Related Terms: Alloys,

Case,

Center,

Die,

Edge,

Hardware,

Lines,

Projection Welding,

Ram,

Run,

Stroke,

Tapping,

ThicknessView Glossary of Metalforming Terms

See also: Dallas Industries

Technologies: Coil and Sheet Handling, Cutting, Stamping Presses

Video

Video