Press-Feed Control Automatically Generates a Smooth, Sinusoidal Motion Profile

January 1, 2011Comments

Dallas Industries, Troy, MI, introduced Fabtech attendees to its exclusive, new ProfileSelect Feed Control that automatically matches the speed of feed advance to the available feed window and press-speed requirement. Users can select from three settings:

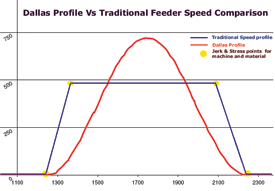

• Smooth profile uses a softer accel/ decel (sinusoidal) motion profile;

• Standard profile automatically matches standard (trapezoidal) accel/decel

With the ProfileSelect system, stampers input press speed (strokes/min.), feed-angle window and feed length. ProfileSelect then utilizes the full feed window of the press to automatically generate a smooth feed-motion profile to complete the length requirement in the allotted feed window.

Previous feed controls use a trapezoidal motion profile, which can create quick, sudden motions that increase the chance of slipping, strain the die and material and damaging the part surface. The ProfileSelect’s sinusoidal profile provides a smooth motion and material feed while utilizing 100 percent of the press-feed window.

The system is available on the company’s new units, as well as a retrofit package for Dallas controls produced since 2005; add a control update package to retrofit it to older Dallas controls.

Dallas Industries: 248/583-9400; www.dallasindustries.com

See also: Dallas Industries

Technologies: Coil and Sheet Handling