Precision Blanking Line Three Times Faster, Quicker to Set Up

January 1, 2010Comments

A new blanking line keeps eight stamping presses flush with material, turning out anti-slip safety grating for the railroad, construction and other industries.

The U.S. freight-car industry has felt the economic meltdown as much or more than any other industry, watching new-car orders fall from 60,000 in 2008 to an estimated 18,000 in 2009. That trend has supplier Morton Manufacturing Co., Libertyville, IL, a provider of anti-slip walking surfaces to railroad-car builders since 1903, eyeing the freight-car repair market for opportunities to provide its manufactured products—running boards, brake steps, end platforms and intermodal platforms. The company, which occupies a 200,000-sq.-ft. facility that takes in two to three truckloads of steel per day, processes coils as wide as 48 in. that weigh as much as 30,000 lb. Most of what Morton processes is 11- to 14-gauge hot-rolled and pre-galvanized steel; it also yields 500,000 lb. of aluminum stock each year, and a bit of stainless steel as well.

The overwhelming majority (80 percent) of the material processed at Morton runs through its seven blank-fed stamping presses, rated 400 to 800-ton capacity; one Minster press processes coil stock. The newest addition to the firm’s pressroom is an 800-ton Clearing added in 2007. Additional value-added processing of the firm’s safety grating products—including products for the industrial market such as work platforms, stair treads, ladder rungs and walks—occurs at its three Amada turret presses, a Whitney plasma-punch machine, 25 press brakes, and welding and finishing lines.

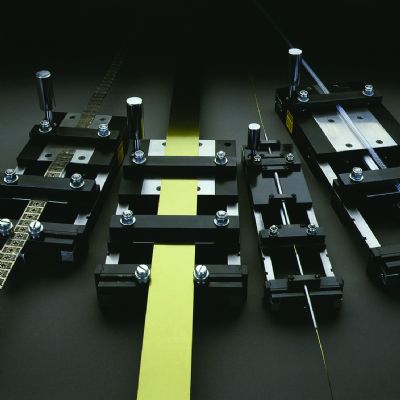

High-Speed Precision Blanking

Converting nearly 100,000 lb. of steel coil per day into blanks at Morton Mfg. falls on the shoulders of its new precision blanking line, a 0.135-in.-capacity line from Red Bud Industries, Red Bud, IL. Morton installed the line in August 2008 to replace a 1974-vintage Red Bud blanking line that, while continued to run well, simply could not keep up with Morton’s work load.“At that time,” recalls Morton Mfg. president Michael Ogden, harking back to late 2007 and early into 2008, “our blanking line was running three shifts a day, all week long, and it still could not meet our demand for blanks. We were forced to outsource some of our preprocessed blanking needs, and so decided to upgrade our blanking operation with a new and much more productive Red Bud line. Our new machine runs three times faster (120 to 150 ft./min.) than did the old one, and setup times are much quicker as well.”