New PLC Controls Promise Quicker Feed-Line Install, Setup

April 21, 2020Comments

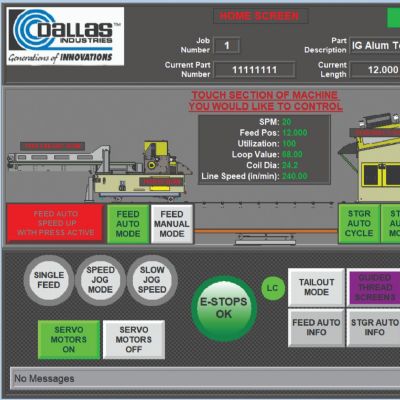

Next-generation PLC controls from Coe Press Equipment offer multiple advanced features to reduce the time required to commission new feed lines, according to company officials. New loop and press simulation capabilities, for example, enable Coe to test, debug and perform a complete startup prior to shipping, decreasing setup time on a metal former’s plant floor by 50 percent or more. A new user-friendly human-machine interface (HMI) logically guides operators through the setup process, and Work Roll Advisor and Feed Roll Advisor software now are embedded into the controls―all contributing to eased setup and changeover.

Next-generation PLC controls from Coe Press Equipment offer multiple advanced features to reduce the time required to commission new feed lines, according to company officials. New loop and press simulation capabilities, for example, enable Coe to test, debug and perform a complete startup prior to shipping, decreasing setup time on a metal former’s plant floor by 50 percent or more. A new user-friendly human-machine interface (HMI) logically guides operators through the setup process, and Work Roll Advisor and Feed Roll Advisor software now are embedded into the controls―all contributing to eased setup and changeover.New features include Loop Simulation, which emulates material to see how the straightener reacts to changes from the feed; and Press Simulation, which simulates press operation with strokes/min. changes, and parameters related to feed angles, pilot, start feed and more. Other features: On the Fly, which automatically changes feed speed to adapt to press speed; Direct Speed Enable, where the straightener automatically hits a target speed at the first press stroke; and Work Roll Simulation, a visual guide to help operators see what’s happening inside of the straightener. Another, Smart Speed, automatically adjusts to optimal line speed based on press speed and feed window.

See also: Coe Press Equipment Corporation

Technologies: Coil and Sheet Handling