Produce Hinges Without Two Tool Sets, and Without Welds and Fasteners

May 5, 2023Comments

The One-Hit-Hinge tool from Mate Precision Technologies improves

upon traditional forming of hinges on a punching machine using two tool sets

where one tool forms the pre-curl in two hits, and the second tool closes the

hinge. This not only requires three total forming strokes, but the machine gap

limits hinge diameter.

The One-Hit-Hinge tool from Mate Precision Technologies improves

upon traditional forming of hinges on a punching machine using two tool sets

where one tool forms the pre-curl in two hits, and the second tool closes the

hinge. This not only requires three total forming strokes, but the machine gap

limits hinge diameter.

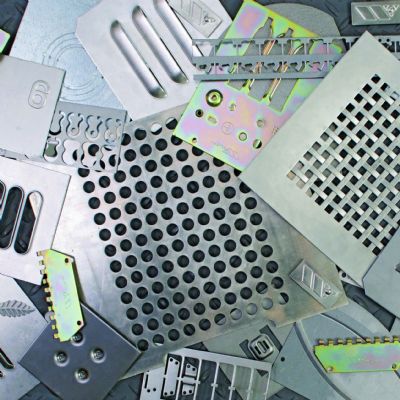

Alternatively, the Mate One-Hit-Hinge forms two sections of a curl on two separate knuckles, creating a closed circle. When assembled with mating forms, the pin is held securely in place by 360-deg. contact. Because the One-Hit-Hinge does not have to be formed straight up and curled down, the hinge diameter can be larger and will not interfere with the machine gap. Overall production enhancements include reduction of the number of tool hits, increased form size and reduced part cost.

The tool is a game-changer for hinge applications such as metal enclosures, access panels, metal cases and electronic cabinets, according to Mate officials. It eliminates the need for separate hinges, spot welds, fasteners or other downstream assembly operations. And, eliminating the need to attach the hinge also increases accuracy, with no chance of the hinge being spot welded in the wrong place, and without the use of welded joints that can fail in the field.

The One-Hit-Hinge tool, available in most tooling styles, can be used on mild steel and aluminum ranging from 0.030 to 0.080 in. thick, and may be suitable for stainless steel in specific applications.

See also: Mate Precision Tooling

Technologies: CNC Punching

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Materials

MaterialsPunching Through the Barriers: Processing Advanced High-Stre...

Saturday, March 29, 2025

Scotchman Industries Names Kent Bradley Director of Marketin...

Tuesday, February 25, 2025

CNC Punching

CNC PunchingWilson Tool Acquires German Tool Manufacturer

Wednesday, September 18, 2024

CNC Punching

CNC PunchingWilson Tool Appoints Adrian Alday Chief Financial Officer

Thursday, August 15, 2024