New Turret-Press Tools Productively Add Details

July 1, 2015Comments

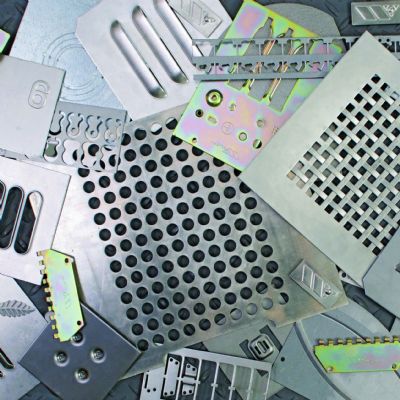

Mate Precision Tooling, Anoka, MN, has introduced Roller Solutions tooling that allows fabricators create rib, shear, offset and pincher features in sheetmetal. Compared to traditional methods utilizing progressive-forming tools, this tooling, according to company officials, increases productivity when creating detailed metal forms.

Mate Precision Tooling, Anoka, MN, has introduced Roller Solutions tooling that allows fabricators create rib, shear, offset and pincher features in sheetmetal. Compared to traditional methods utilizing progressive-forming tools, this tooling, according to company officials, increases productivity when creating detailed metal forms.

Rolling Rib tooling reportedly reduces time needed to create stiffening ribs in products requiring additional strengthening. The ribs may be created in any contour, and started or ended anywhere on the sheet. Rolling Shear tooling, used for slitting and nibbling operations, can improve these functions by virtually eliminating burrs and reducing scrap, and can perform high-speed straight-line and contour cutting.

Rolling Offset tooling creates offsets and eliminates the need for press-brake secondary-forming operations. It quickly creates straight-line and contoured offsets. Rolling Pincher tooling enables quick and clean burr-free separation of parts from surrounding metal. Via precise scoring, the tooling reportedly creates high-quality-edge parts that snap easily from the sheet.

Designed for thick-turret B-station applications, Roller Solutions tooling handle high-speed applications—equal to the programmed table travel speed. The tooling works on a range of materials including stainless steel, mild steel and aluminum.

Mate Precision Tooling: www.mate.com

See also: Mate Precision Tooling

Technologies: CNC Punching

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. CNC Punching

CNC PunchingScotchman Industries Names Kent Bradley Director of Marketin...

Tuesday, February 25, 2025