Demand-Flow Sheetmetal Fabrication, Assembly

March 1, 2008Comments

|

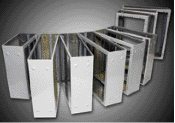

Hess Industries, Niles, MI, introduces its Demand Flow sheetmetal fabrication and assembly systems that manufacture families of parts for HVAC components such as A/C coil guards, base pans and tops; furnace doors, tops and air-filter housings; and white-goods components—washer/dryer drums, wraps, refrigerator doors, etc. Benefits include product-mix flexibility, reduced tooling and labor cost, reduced inventory and work in process, and optimized floor-space use. A typical Demand Flow system incorporates programmable punching, piercing, forming, shearing and assembly stations to manufacture a family of parts, with changeover occurring seamlessly and on-the-fly.

Stop by its booth to discuss the HVAC featured system, which manufactures 17 different furnace air-filter housings on a single line.

www.hessindustries.com

See also: X

Technologies: CNC Punching