High-Strength Energy Crisis

May 1, 2010Comments

Last month a reader submitted a question regarding press tonnage calculations. The reader had commented, “On several occasions we had to move our dies to a larger press because the press we selected did not have enough power. In fact, the press slowed down noticeably during production. When we moved the die to a larger tonnage press the problem went a.” His concern was that his engineers were using incorrect formulas when calculating the required press forces

As it turned out, the force calculations that were used had some flaws; primarily, not including the force required to counteract the draw pad forces. Nor was the reduction in available working force (de-rated tonnage) considered as the distance above bottom of the press stroke increased. Still, the inaccurate calculations were close enough to get the job assigned to a press with adequate tonnage capacity. Why, then, does the company continue to have problems (i.e., slowing down of the press) running this particular job? And, why does the problem go a when the die is moved to a press with greater tonnage capacity?

Simply stated, this company has an energy shortage. If they plan to deep draw similar parts from higher strength materials or some of the new advanced high-strength steels (AHSS), they will find themselves in the midst of a full-blown energy crisis.

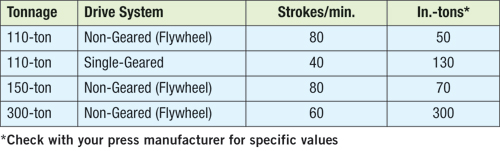

|

| *Check with your press manufacturer for specific values |

The tonnage rating of a press is the maximum load that can be exerted in continuous operation without causing damage to the machine structure or its drive system. The energy rating of a press deals with the product of the applied press load and the distance through which the load must be applied. Since energy is expended with each stroke of the press—and this energy must come from somewhere—attention should be focused on the main drive motor and the flywheel.

The main motor is the only source of energy for the stamping press. The motor must have sufficient horsepower to supply the demands of the entire stamping operation. The press flywheel, by virtue of its mass and rotational speed, serves as the energy storage device. The energy in the flywheel is expressed as in.-tons of torque. In combination, the flywheel stores and delivers the required work energy while the electrical motor restores depleted energy by maintaining flywheel speed and avoiding excessive slowdown.

Deep-drawing operations consume large amounts of press energy due to their long working distances, sometimes beginning several inches above the bottom of the press stroke. For example, pushing 50 tons through 1 in. of deep drawing would require 50 in.-tons of energy while a 3-in. deep draw requires 150 in.-tons of energy.

The table describes four mechanical presses, specifying tonnage and energy capacity. Referring back to the previous example, every machine listed in the table has an adequate tonnage rating to carry out the 3-in. deep draw (50 tons is required). However, only one of the presses has enough energy (150-in. tons is required). This company literally has an energy shortage. Only one of the four machines actually has enough energy to run the job.

Unfortunately, most stamping companies don’t consider energy requirements in their press-selection process, even though the data is readily available from the manufacturer’s technical specifications. Omitting the energy data column (in.-tons) from the table would surely lead to the improper selection of a stamping press. Most stamping companies would not select a 300-ton press to run a stamping process requiring only 50 tons of force when three other lower cost (lower-tonnage) machines also are available.

What happens when the customer changes the part material to a higher-strength steel grade? Let’s assume that the material change will require 80 tons of force working through the same 3-in. distance. This would require a machine with 240 in.-tons of energy. Again, all four machines are within the rated force capacity, but only one has enough energy.

Or does it?

|

Stamping high-strength steels requires higher blankholding forces and punch forces that result in increased frictional forces and interface temperatures. When interface temperatures reach a critical point, lubrication breakdown and other forming- and die-related problems can arise. During a production run, it would not be uncommon to reduce the press speed in order to lower the process operating temperatures and eliminate thermal-related forming problems.

Notice that the energy data for each of the machines in the table relates to specific operating speed, reported as strokes/min. (SPM). When the press speed is reduced below a critical point, available energy can diminish rapidly.

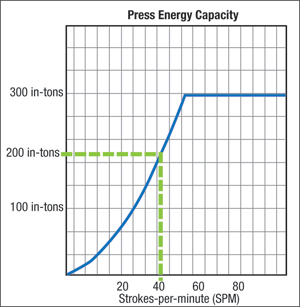

The illustration above represents the energy curve for the 300-ton press in the table. This machine has full-rated energy at 60 SPM. If press speed were reduced to 40 SPM to reduce the amount of heat being generated or to mitigate other forming-related problems, the available energy drops to less than 200 in.-tons.

This company now is in the midst of an energy crisis. They have plenty of machines with the required tonnage rating but none have the necessary energy capacity. This supplier soon will discover that they cannot produce these parts for their customer.

If the words “energy crisis” aren’t enough to turn your attention to the energy capacities of the machines in your press shp, especially if you plan to stamp any advanced high strength steels, maybe 'breech of contract" will. MF

View Glossary of Metalforming Terms

Technologies: Bending

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Bending

BendingCreative Approaches to Common Press Brake Challenges, Part 1...

Justin Talianek Tuesday, April 30, 2024

Bending

BendingEnergy-Saving All-Electric Rolling Machine Boasts Speed, Acc...

Wednesday, March 20, 2024