Enhanced Capability–ODM Tool & Manufacturing

ODM Tool & Manufacturing, McCook, IL, a medium- to heavy-gauge metal-stamping and assembly manufacturer located near Chicago, recently was contracted to design and build tooling to stamp pickup-truck transmission mounts for a Tier 1 rubber-molding company. Finished parts route to a major automotive OEM. During the stamping process, a large portion of each mount is coined to reduce the thickness of the steel to accommodate the rubber molding. The pressure needed to coin the parts exceeded the 1500-ton capacity of ODM’s largest press.

Determine if Outsourcing is Right for Your Company

…by considering these areas of concern:

- Develop confidentiality agreements, if necessary.

- Ensure there are no legal issues or conflicting customer.

- Understand the logistics of the start-up.

- Have a clear understanding of the financial arrangement.

- Ensure cooperation between each company’s engineering teams.

- The outsourcing company als assumes responsibility for quality and timely delivery.

- Take care to not hurt each other’s reputation in the market place.

- Without confidence and trust between each company, outsourcing won’t work.

Facing a quickly approaching and demanding deadline, ODM president Carl Michaelsen III called Sopko, based on their relationship forged through several years of membership in the Precision Metalforming Association. When they met to discuss the outsourcing project, Michaelsen and Sopko quickly agreed to terms that benefited both companies.

ODM shipped the die for the project to Stamco for its engineering team to review, and ensure that the die would operate properly in Stamco’s 3000-ton press. In 17 days, Stamco was able to adjust its production schedule to set up the die, obtain all necessary materials and steel, and work with ODM engineers on trial runs for PPAP. A final tryout at Stamco, attended by ODM personnel and representatives from the Tier 1 customer, proved successful and the part entered production to meet the OEM’s deadlines.

An Alliance for Growth and Cost Savings–Enterprise Welding & Fabricating

Enterprise Welding & Fabricating, located in the Cleveland, OH suburb of Mentor, specializes in laser cutting, CNC press-brake forming, welding, fabricating and painting. A long-time supplier of large suspension assemblies for a major semi-trailer suspension manufacturer, Enterprise recently was awarded a significant increase in orders. When orders for suspension assemblies were modest and volumes relatively low, the firm’s processes proved efficient and economical. However, the sudden increase in orders and volumes required its engineers to reevaluate production processes.

Working with the OEM customer, the Enterprise management team decided that hard tooling and stamping the suspension-assembly components, rather than continuing with laser cutting and press-brake forming, was the to go. Already familiar with Stamco’s capabilities through previous work, the OEM suggested a partnership between Enterprise and Stamco.

“Enterprise has the welding and assembly expertise and Stamco has the stamping equipment and the knowhow to produce large, complex high-volume stampings,” says Enterprise general manager Chris Weinkamer.

To convert the laser-cut and press-brake-formed parts over to stamping, teams from Stamco and Enterprise worked to accommodate the idiosyncrasies of stamping. For example, the laser-cut parts had 45-deg. corners and the stampings had rounded corners. That meant taking a design well-suited for laser cutting and making it work as a stamping.

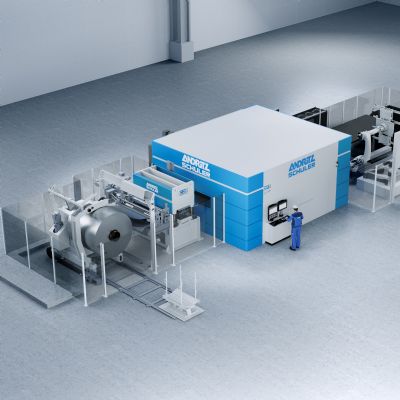

Stamco stamps this part for ODM Tool & Manufacturing, a pickup-truck transmission mount of 5.2-mm-thick high-strength low-alloy steel. A large portion of each mount is coined to reduce thickness of the steel to accommodate rubber molding around the part, to provide vibration dampening. The pressure needed to coin the parts exceeded the 1500-ton capacity of ODM’s largest press.

Nine large progressive dies were built at a cost of $750,000, which the OEM covered. For this tooling investment, the OEM realized an annual savings of $1 million. And, because of the increased volumes, the OEM also agreed to purchase mill-quantities of steel, which further reduced its costs. In the end, stamped parts were shipped to Enterprise for welding, assembly and finishing.

Benefits of this alliance were three-fold:

- Lowering its manufacturing costs enabled Enterprise to remain competitive and keep the work in the United States.

- Stamco increased the volume of work it was doing for the OEM, and increased its stamping capacity.

- The OEM will save millions of dollars during the life of the alliance.

Outsourcing Creates New Opportunities

These alliances illustrate the benefits of stampers outsourcing to increase capacity, expand capabilities and spur growth without significant investments for new equipment or plant space—some of the many strategic, operational and financial advantages of outsourcing. MF

View Glossary of Metalforming Terms

Technologies: Stamping Presses, Cutting, Bending