Shop vs. Site Work

Sickle’s 50,000-sq.-ft. fabrication shop employs five people, while another 10 employees work in the field installing all of the sheetmetal that the shop fabricates, as well as purchased HVAC equipment. Duct Fabricators worked on most of Cleveland’s landmark buildings, including Quicken Loans Arena, the Great Lakes Science Center and the Rock and Roll Hall of Fame and Museum.

In 2008, for example, the firm was entrusted to upgrade the air-handling systems operating within the Cleveland Museum of Art. Renovating the facility’s pair of 1916-vintage buildings, as well as constructing wings to connect the buildings, required Duct Fabricators to install and integrate several air-handling units, 16 smoke-evacuation systems and ductwork of galvanized and stainless steel 24 to 10 gauge, with specialized isolation and sound-dampening requirements. In an e-newsletter article published by the Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA), Sickle stated that, “working within the confines of the existing structure was a primary challenge.” The article also noted that ductwork was “strategically placed between 90-yr.-old columns, and smoke evacuation systems were carefully lodged directly below 1916-vintage skylights.”

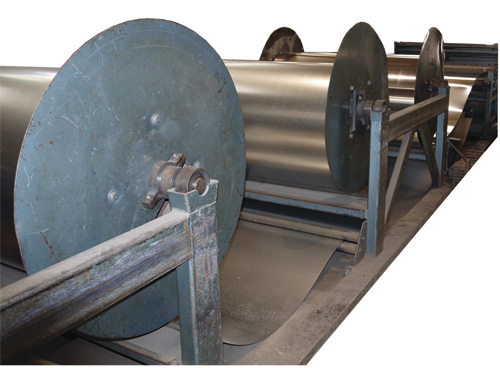

In addition to its automated duct line, Duct Fabricators operates an array of fabricating equipment, including the plasma-cutting and rollforming machines shown here.

Overall, 55 percent of its total workload occurs in the shop, the rest in the field. Anywhere from three to six projects occupy the shop floor at any one time, the average project taking 6 to 8 months to complete, even though some projects can take 2 to 3 years to conclude.

When the high-rise commercial construction market dried up in Cleveland 10 to 15 years ago, as it did in so many traditionally rust-belt cities, Sickle and his team repositioned the company to focus on other more lucrative markets—hospitals and sewage-treatment plants, most notably.

“Hospitals are a completely different animal,” Sickle notes. “Laying out ductwork in hospitals requires us to maneuver amongst and around medical-gas lines, tube systems, telecommunications cable and such. The ductwork, therefore, takes a lot more twists and turns and requires more fittings and connections than does the ducting that goes into a high-rise commercial building, where the runs tend to be straight with simple branches connected to move air in and out of offices.”

Automated Line

While the Duct Fabricators fabrication shop includes a CNC plasma-arc-cutting machine, rollforming line, shear and press brake, the overwhelming majority of the sheetmetal processed here runs through an automated duct line. The line, an Iowa Precision Industries’ Fabriduct model, produces wrap-around and L-shaped duct sections in 5-ft. lengths. It holds as many as six coils of material—cold-rolled carbon steel, stainless steel and aluminum, in varying gauges prestaged and ready to roll.

From his control panel, an operator initiates the automated setup that begins with the steel running through a leveler. Then stiffening beads can be added if needed, and tie-rod holes and notches added to facilitate assembly. A shear cuts sections to length before snap-lock or Pittsburgh seams are formed to facilitate assembly. Before the duct sections then are wrapped into a one-piece duct or formed into an L shape, the operator can program the Fabriduct to apply a sound-attenuation liner to the inside of the duct.

Aside from its automated duct line, Duct Fabricators has looked to parlay its other fabrication capabilities into custom sheetmetal fabrication. “In the last couple of years,” Sickle notes, “we’ve consumed time on our press brake and plasma cutting machine to fabricate metal stairs, and we’re also busy press-brake forming plate for our neighbors, Cleveland Tank and Supply, a manufacturer of fuel systems.

“Lately,” adds Sickle, “we’ve been taking on a lot of stainless-steel fabrication, and we’re even fabricating ductwork for some of our competitors in the contracting business.” MFView Glossary of Metalforming Terms

See also: Iowa Precision Industries, Inc.