“We regularly have to fit complex and precise processes into confined, compact areas,” explains Sean Devereux, a mechanical design engineer at Labman. “Often, that means coming up with weird and wonderful fixtures and fittings that make the impossible possible. The design freedom 3D printing offers appealed in this respect, as we knew we could create new shapes, consolidate parts into singular structures, and use different methods and materials to make parts lighter—great for the ends of robotic arms, for example. Essentially, we knew it would enable us to extend our design rulebook to solve problems in new and inventive ways.

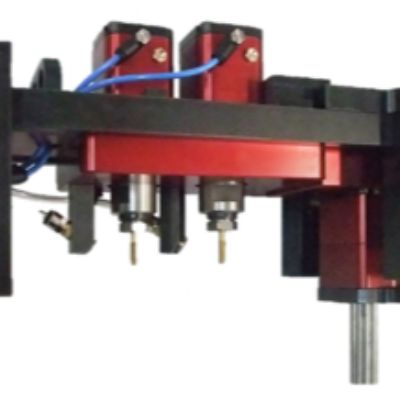

“For instance, we had one project where samples had to be held in a particular way while allowing water to be shot at them,” Devereux continues. “The space restrictions and precision angles required for water application meant we were facing a real head-scratcher in terms of meeting the customer’s exact requirements. Using traditional techniques, it might very well have been impossible. But with 3D printing, we were able to embed the actual gripper into another part and create internal channels to deliver the water to the sample in precisely the right way. 3D printed parts may end up accounting for less than 5 percent of a total system, but when you can solve issues like this, it can end up being one of the most important design aspects.”

Convinced by Creative Convenience

What the team had not expected was how easy it would be to adopt AM and that this would in turn deliver significant benefits. Labman project engineer Tom Gale explains how the Materialise OnSite online 3d printing service enables it to submit a CAD file, receive a quote and then have a 3D-printed part created and delivered, all in a matter of days. “It’s perfect for us,” says Gale. “We simply submit our designs with exact specifications and receive the part back exactly as intended.

|

Polyamide aluminum-filled (PA-AF, previously called Alumide) from Materialise is a blend of aluminum and polyamide powders, which allows the machining of metallic-looking, nonporous components, and is resistant to high temperatures (130 C).

“Alumide provides one unique advantage in its ability to reduce weight compared to conventional technologies, without compromising on other structural requirements,” says Bart Wilberts, general manager of RapidFit, an automotive-tooling manufacturer in Leuven, Belgium. “We can provide a solution that reduces the weight of a simulation by 30 percent using lightweight material combinations and 3D printing. With Alumide, we not only reach our weight target, but can enhance the build in terms of cost and accuracy. Change management between simulation models also is easy, fast and cost effective when using Alumide for checking volumes in parts such as headlights, radiator grills or other similar items for the automotive market. Further, using these technologies allows us to answer requests in a very limited timeframe with high-quality results.”

|

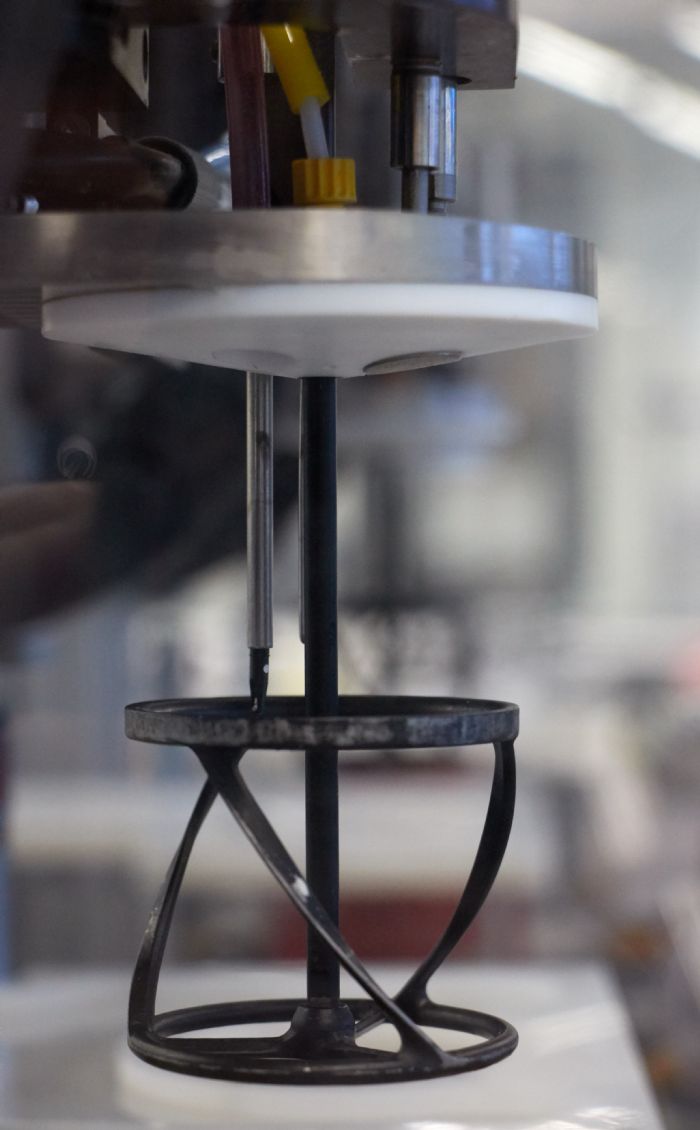

“Everything we create for customers is bespoke,” continues Gale, “and a large percentage of a project lies in the design process—developing a blade with the right twist profile to mix a powder in precisely the right way, for example, or a gripper that enables a sample to be treated but not tainted. It takes a lot of time to test our ideas and find the right answer. Before we adopted AM, building some of these parts, testing them, tweaking the design and building them again all could take an incredibly long time. Now we can quickly and cost effectively print multiple prototype iterations to find exactly the right solution. And, because we’ve been able to find a way to utilize 3D printing easily with OnSite, going from initial idea to final proof of concept is far quicker, which ultimately is more profitable for us and most cost effective for our customers.”

Project-By-Project Adoption

Labman’s design process involves a detailed User Requirement Specification (URS) analysis, mapping out exact functionality and performance details and breaking down key goals—dispensing a liquid in a certain way or channelling airflow over samples/materials, for example—before the team embarks on an intense design study to develop the right solution.

“We quickly began to see URS requirements that really leaned themselves to 3D printing, not just in terms of general suitability—I mean specific functionality common to the types of clients we work with”, explains Gale. “For example, we often need to keep cabling in place to maximize space in tight spots, while also ensuring that those cables are protected against power or liquid ingress. This used to mean developing awkwardly shaped brackets that were time-intensive and expensive to make.”

With 3D printing this is not the case. What Labman also discovered was the increased flexibility that AM gave them in terms of changing briefs. Gale continues, “It is pretty common for requirements to change midway through a project, perhaps because of new functionality the customer wants or because other components are behaving in a slightly different way to what was expected. 3D printing really helps in these scenarios as you can quickly adapt the design and, in the case of using OnSite, get a new part delivered to fit the new spec.

“With every new project or adaptation, we discover more,” he adds. “That’s how it goes, you try something new, you learn something new, you share that information—so while we’re pushing boundaries, we’re also making these new techniques part of the everyday process. It’s worked so well that we’ve essentially been able to develop ‘trademark’ 3D-printed elements that we are known for, such as our mobile dispensing units, parts we can then easily manufacture in small lots.”

Supporting Systems as Shop Windows

For Labman inventor Rob Hodgson, another important factor that has supported the company’s rapid adoption of AM has been customer reaction. “In addition to 3D printing parts for prototyping/feasibility testing, the quality of the materials means that we can use printed components on our finished production machines,” he says.

“For example, with a material like Materialise’s PA-AF (previously called Alumide, a blend of aluminum and polyamide powders), we can tap it or put in threaded rivets,” Hodgson explains, “so it’s perfect for making complex metal components that also can be replaced easily if needed. And, because we can use AM in this way, we also can improve the aesthetics of the solutions that we design. For example, many of the parts that we create, say in PA-AF or stainless steel, negate the need for awkward, unattractive solutions and messy cable areas. They just look better.

“Remember, these often are very expensive machines that reflect major capital investment. First and foremost, these robots have to do a job, but for many of our blue-chip clients, how they look is really important. Recently, for example, we worked on a state-of-the-art robot for Liverpool University’s Materials Innovation Factory. The solution we provided, which features many bespoke 3D-printed components, represents the university—it has to look the part. It is a showpiece for them and effectively a shop window for us. It’s just another great business benefit that has further strengthened our adoption process.

“All of these benefits combined,” Hodgson summarizes, “plus the way we’ve been able to partner with Materialise, has meant that we’ve quickly normalized something new and made it work for us.”

‘Normalizing New’ Down to Picking the Right Partner

Having the ability to blend inhouse design expertise with outsourced production through the Materialise OnSite service has helped Labman quickly realize a number of key benefits. As Hodgson explains, “What we’ve been able to do is normalize something new by finding a way of working that suits us, and the right AM partner to help get us moving quickly.

“We’ve then been able to build on this foundation to flex our capabilities,” he continues. “While we have the inhouse knowledge to give exact 3D-print spec and processing briefs through OnSite, we also know we can call on the design team at Materialise to help us with specific projects that may require more AM experience—for instance, where we might have tolerance issues for certain material combinations. On the flip side to that, we’ve also introduced our own 3D printer that we can turn to when needed. Essentially the options that we now have in our toolbox means we always have a solution to suit specific project needs.” 3DMP

Article provided by Materialise.

See also: Materialise USA LLC

Technologies:

In fact, in just 3 years Labman has gone from never using metal AM to having printed parts in nearly every automation system it develops. The change has made a big difference. Why? Because as well as helping the U.K. business push boundaries with design, making metal AM part of its everyday toolkit has helped it save its most precious commodity: time. By simplifying prototype and end-part creation for complex components, otherwise time-consuming, laborious and costly to create, the company has been able to shave days from its design process and deliver replacement parts quickly, all while allowing the business to put its own stamp on the robots it creates.

In fact, in just 3 years Labman has gone from never using metal AM to having printed parts in nearly every automation system it develops. The change has made a big difference. Why? Because as well as helping the U.K. business push boundaries with design, making metal AM part of its everyday toolkit has helped it save its most precious commodity: time. By simplifying prototype and end-part creation for complex components, otherwise time-consuming, laborious and costly to create, the company has been able to shave days from its design process and deliver replacement parts quickly, all while allowing the business to put its own stamp on the robots it creates.