Industry Looks to 3D Printing For Innovative Alternatives

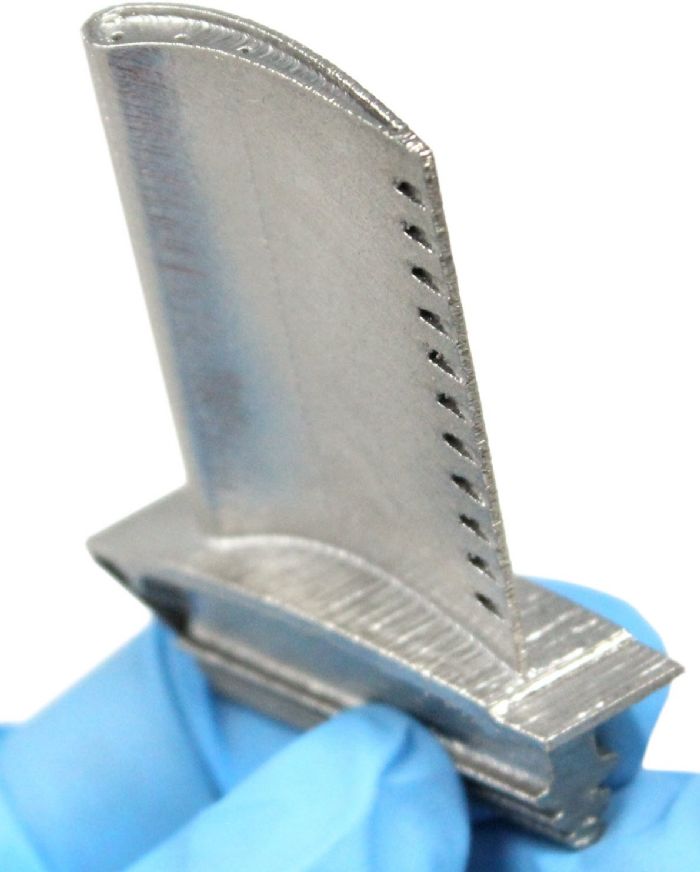

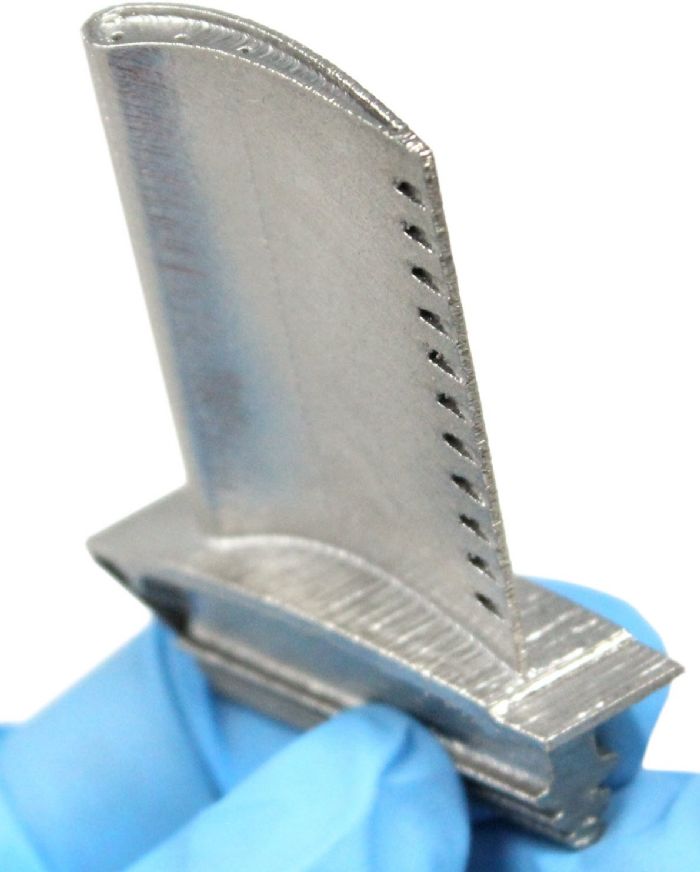

With such material considerations in mind, aviation, aerospace and heavy industries have begun looking at additive manufacturing (AM) of superalloys as potential game-changing technology. AM can deliver complex, previously unmanufacturable, innovative designs that boost product performance while reducing supply-chain delays and associated production costs. Particularly in high-temperature gas turbines—traditionally assemblies of tens-to-hundreds of parts including tubes, flow paths and sheet metal structures that must be formed and welded to other components—AM presents some highly attractive opportunities for design simplification and part consolidation.

With such material considerations in mind, aviation, aerospace and heavy industries have begun looking at additive manufacturing (AM) of superalloys as potential game-changing technology. AM can deliver complex, previously unmanufacturable, innovative designs that boost product performance while reducing supply-chain delays and associated production costs. Particularly in high-temperature gas turbines—traditionally assemblies of tens-to-hundreds of parts including tubes, flow paths and sheet metal structures that must be formed and welded to other components—AM presents some highly attractive opportunities for design simplification and part consolidation.

Given the desirable qualities that superalloys can deliver, it’s perhaps not surprising that companies beginning to explore the potential of AM are asking for equipment—or access to contract manufacturers running advanced industrial AM systems—that can handle such material.

AM machine providers, in turn, are embracing the opportunity

to use their technology to solve problems encountered by engineers when using

traditional manufacturing to make high-performance, mission-critical components

from superalloys. Response to this demand is met, however, with inherent challenges

to perfecting the superalloy 3D-printing process.

AM machine providers, in turn, are embracing the opportunity

to use their technology to solve problems encountered by engineers when using

traditional manufacturing to make high-performance, mission-critical components

from superalloys. Response to this demand is met, however, with inherent challenges

to perfecting the superalloy 3D-printing process.

Fine-Tuning the Process

Metal AM, essentially a micro-welding operation in which a geometry-directed

laser beam melts ultra-thin layers of material sequentially to build up a

three-dimensional part, is impacted by material purity. While many OEMs have

their own recipes for metal powder, quality standards allow for a range of

certain elements within an alloy, which means there can be more or less oxygen or

carbon in a superalloy formula. With HastX, lower carbon content leads to

better results; the most successful print runs occur when material choice

controls for that.

Another issue: HastX can create base-metal soot or condensate during the laser-sintering process, fouling the surrounding powder. Soot landing directly on the powder bed can cause issues with energy absorption. Or, if the gas flow used to flush out the chamber during AM doesn’t completely evacuate the soot, the chamber volume can become loaded with airborne condensate that blocks the laser beam itself. Such occlusion changes the amount of power delivered to the powder bed and interferes with the welding process.

To ensure clean gas flow around a part being sintered from

HastX, next-gen AM systems operate in an argon-gas environment that keeps oxygen

levels extremely low. While other systems use nitrogen, argon typically

delivers better results throughout a build.

Lastly, AM of HastX can lead to hot cracking—less of a problem than with some other superalloys, but still something that requires attention, particularly when building thin-walled, high-heat structures. Here, precise directing of the thermal energy of the laser is key, due to how the active meltpool cools and solidifies during an AM build. Cooling and solidification depend greatly on what’s around the build—usually metal on one side and powder on the other. Powder is an insulator that does not conduct heat well; as a layer cools, that thermal energy predominantly transfers into the newly created thin metal walls. Too much thermal energy in the wrong place can weaken and warp the structure. Therefore, it’s critical that the laser power be applied at the precise location and strength every millisecond—an attribute of the in-process monitoring and feature-specific parameter control provided by some AM systems.

Matching the Material to the Application

Given the variety of challenges inherent in matching materials to production processes, it’s interesting to note that many AM-machine makers now have portfolios of as many as 40 different materials. Yet, in many cases the cost of printing doesn’t align with the material chosen. The application space also can be limited.

Suppliers of newer AM systems have prioritized customer and market considerations, and consciously limited the range of applications for which they’ve developed their exacting AM processes and accompanying software. Capabilities such as support-free manufacturing (at angles now down to fully horizontal overhangs) of extremely thin-walled parts align well with high-temperature applications involving fluid flow and heat exchange. This, in turn, dovetails well to the production of parts and components made from HastX and other superalloys. 3DMP

See also: Velo3D

Technologies:

With such material considerations in mind, aviation, aerospace and heavy industries have begun looking at additive manufacturing (AM) of superalloys as potential game-changing technology. AM can deliver complex, previously unmanufacturable, innovative designs that boost product performance while reducing supply-chain delays and associated production costs. Particularly in high-temperature gas turbines—traditionally assemblies of tens-to-hundreds of parts including tubes, flow paths and sheet metal structures that must be formed and welded to other components—AM presents some highly attractive opportunities for design simplification and part consolidation.

With such material considerations in mind, aviation, aerospace and heavy industries have begun looking at additive manufacturing (AM) of superalloys as potential game-changing technology. AM can deliver complex, previously unmanufacturable, innovative designs that boost product performance while reducing supply-chain delays and associated production costs. Particularly in high-temperature gas turbines—traditionally assemblies of tens-to-hundreds of parts including tubes, flow paths and sheet metal structures that must be formed and welded to other components—AM presents some highly attractive opportunities for design simplification and part consolidation. AM machine providers, in turn, are embracing the opportunity

to use their technology to solve problems encountered by engineers when using

traditional manufacturing to make high-performance, mission-critical components

from superalloys. Response to this demand is met, however, with inherent challenges

to perfecting the superalloy 3D-printing process.

AM machine providers, in turn, are embracing the opportunity

to use their technology to solve problems encountered by engineers when using

traditional manufacturing to make high-performance, mission-critical components

from superalloys. Response to this demand is met, however, with inherent challenges

to perfecting the superalloy 3D-printing process.

Event

Event