Page 44 - MetalForming September 2016

P. 44

How Tonnage Impacts Press-Brake Bending

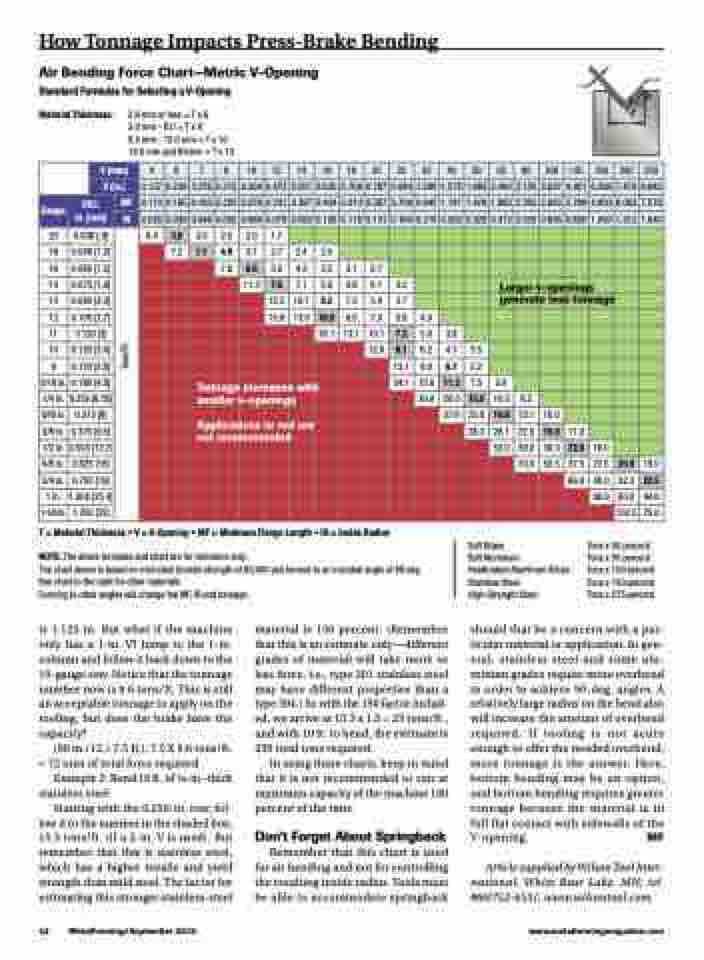

Air Bending Force Chart—Metric V-Opening

Standard Formulas for Selecting a V-Opening

T

IR

Material Thickness:

2.6 mm or less = T x 6 3.0mm-8.0=Tx8 9.0mm-12.0mm=Tx10 14.0mmandthicker=Tx12

MF V

V(mm) 4 6 7 8 10 12 14 16 18 20 25 32 40 50 63 80 100 125 160 200 250 V (in.) 0.157 0.236 0.276 0.315 0.394 0.472 0.551 0.630 0.709 0.787 0.984 1.260 1.575 1.969 2.480 3.150 3.937 4.921 6.299 7.874 9.843 MF 0.110 0.165 0.193 0.220 0.276 0.331 0.397 0.454 0.510 0.567 0.709 0.945 1.181 1.476 1.860 2.362 2.953 3.789 4.850 6.063 7.579

Gauge

20 18 16 14 13 12 11 10

9 3/16 in. 1/4 in. 5/16 in. 3/8 in. 1/2 in. 5/8 in. 3/4 in. 1 in. 1-1/4 i n .

DEC. in. [mm]

0.036 [.9] 0.048 [1.2] 0.060 [1.5] 0.075 [1.9] 0.090 [2.3] 0.105 [2.7] 0.120 [3] 0.135 [3.4] 0.150 [3.8] 0.188 [4.8] 0.250 [6.35] 0.313 [8] 0.375 [9.5] 0.500 [12.7] 0.625 [16] 0.750 [19] 1.000 [25.4] 1.250 [32]

IR

0.026 0.039 0.046 0.052 0.066 0.079 0.092 0.105 0.118 0.131 0.164 0.210 0.262 0.328 0.413 0.525 0.656 0.820 1.050 1.312 1.640

5.4

3.6

7.2

3.0 5.8

2.5 2.0 1.7

4.8 3.7 2.7 2.4 2.0

7.8 6.0 5.0 4.2 3.5 3.1 2.7

11.3 7.5 7.1 5.6 4.8 4.1 3.2

12.5 10.1 8.2 7.2 5.4 3.7

15.8 13.0 10.5 9.5 7.5 5.6 4.0

Larger v-openings generate less tonnage

16.1 13.1 10.1 7.2 12.0 8.1 13.1

5.0 3.8

6.2 4.7 3.5

Tons/Ft.

Tonnage increases with 24.1 smaller v-openings

Applications in red are not recommended

9.0 6.7 15.0 11.3 30.0 20.0

37.6

5.2

7.5 5.8

15.0 10.5 8.5

25.0 18.8 13.1 10.0

38.3 28.1 22.5 15.0 11.3

52.0 39.0 30.0 22.0 16.0 70.0 52.5 37.5 27.5 66.0 45.0 90.0

T = Material Thickness • V = V-Opening • MF = Minimum Flange Length • IR = Inside Radius NOTE: The above formulas and chart are for reference only.

The chart above is based on mild steel (tensile strength of 60,000 psi) formed to an included angle of 88 deg. See chart to the right for other materials.

Forming to other angles will change the MF, IR and tonnage.

Soft Brass

Soft Aluminum

Heattreated Aluminum Alloys Stainless Steel High-Strength Steel

Tonsx Tonsx Tonsx Tonsx Tonsx

20.0 15.0 32.3 22.5 60.0 44.0 102.5 75.0

50 percent 50 percent 100 percent 150 percent 275 percent

is 1.125 in. But what if the machine only has a 1-in. V? Jump to the 1-in. column and follow it back down to the 10-gauge row. Notice that the tonnage number now is 9.6 tons/ft. This is still an acceptable tonnage to apply on the tooling, but does the brake have the capacity?

(90 in./12 = 7.5 ft.), 7.5 X 9.6 tons/ft. = 72 tons of total force required

Example 2: Bend 10 ft. of 1⁄4-in.-thick stainless steel

Starting with the 0.250-in. row, fol- low it to the number in the shaded box, 15.3 tons/ft. (if a 2-in. V is used). But remember that this is stainless steel, which has a higher tensile and yield strength than mild steel. The factor for estimating this stronger stainless-steel

material is 150 percent. (Remember that this is an estimate only—different grades of material will take more or less force, i.e., type 201 stainless steel may have different properties than a type 304.) So with the 150 factor includ- ed, we arrive at 15.3 x 1.5 = 23 tons/ft., and with 10 ft. to bend, the estimate is 230 total tons required.

In using these charts, keep in mind that it is not recommended to run at maximum capacity of the machine 100 percent of the time.

Don’t Forget About Springback

Remember that this chart is used for air bending and not for controlling the resulting inside radius. Tools must be able to accommodate springback

should that be a concern with a par- ticular material or application. In gen- eral, stainless steel and some alu- minum grades require more overbend in order to achieve 90-deg. angles. A relatively large radius on the bend also will increase the amount of overbend required. If tooling is not acute enough to offer the needed overbend, more tonnage is the answer. Here, bottom bending may be an option, and bottom bending requires greater tonnage because the material is in full flat contact with sidewalls of the V-opening. MF

Article supplied by Wilson Tool Inter- national, White Bear Lake, MN; tel. 866/752-6531, www.wilsontool.com.

42 MetalForming/September 2016

www.metalformingmagazine.com