Page 42 - MetalForming September 2016

P. 42

How Tonnage Impacts Press-Brake Bending

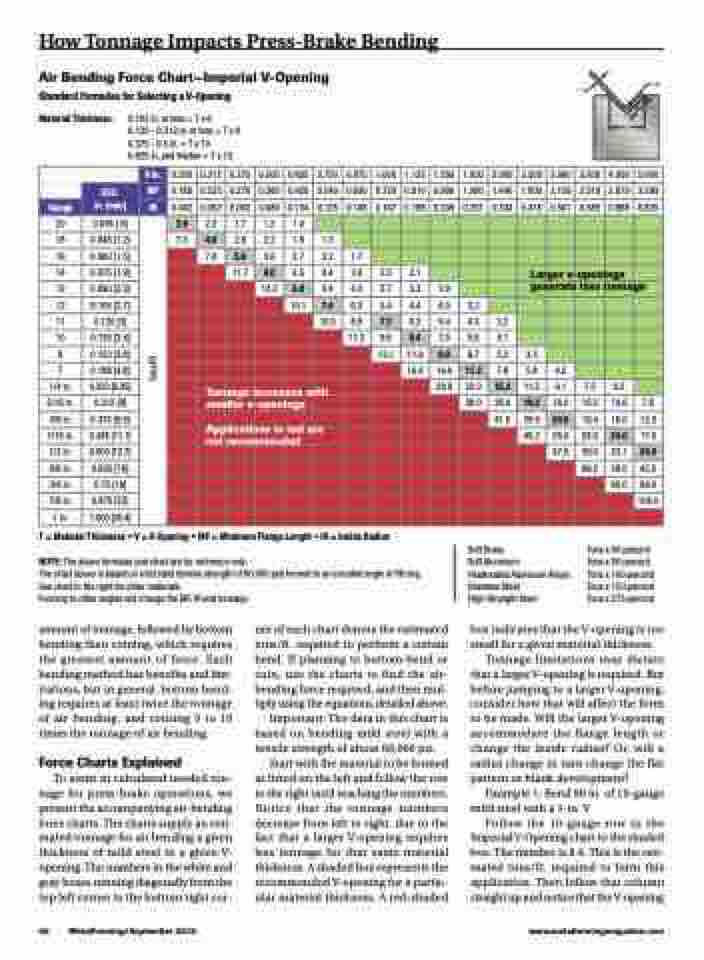

Air Bending Force Chart—Imperial V-Opening

Standard Formulas for Selecting a V-Opening

T

IR

Material Thickness:

0.105 in. or less = T x 6 0.120-0.313in.orless=Tx8 0.375-0.5in.=Tx10

0.625 in. and thicker = T x 12

MF V

V in.

0.250

0.313

0.375

0.500

0.625

0.750

0.875

1.000

1.125

1.250

1.500

2.000

2.500

3.000

3.500

4.000

5.000

DEC. in. [mm]

MF

0.180

0.225

0.270

0.360

0.450

0.540

0.630

0.720

0.810

0.900

1.080

1.440

1.800

2.159

2.519

2.879

3.599

Gauge

IR

0.042

0.052

0.063

0.084

0.104

0.125

0.146

0.167

0.188

0.209

0.251

0.334

0.418

0.501

0.585

0.668

0.835

20

0.036 [.9]

2.9

2.2

1.7

1.2

1.0

18

0.048 [1.2]

7.0

4.0

2.9

2.2

1.6

1.3

16

0.060 [1.5]

7.8

5.6

3.6

2.7

2.2

1.7

14

0.075 [1.9]

11.7

6.0

4.5

3.4

3.0

2.5

2.1

Larger v-openings

13

0.090 [2.3]

12.2

6.8

5.4

4.3

3.7

3.3

2.9

generate less tonna

ge

12

0.105 [2.7]

10.1

7.4

6.3

5.4

4.4

4.0

3.2

11

0.120 [3]

10.5

8.8

7.2

6.2

5.4

4.3

3.2

10

0.135 [3.4]

11.3

9.6

8.4

7.0

5.6

4.1

9

0.150 [3.8]

13.1

11.9

9.0

6.7

5.2

3.5

7

0.188 [4.8]

16.4

14.0

11.2

7.6

5.8

4.5

1/4 in.

0.250 [6.35]

Tonnage increases with

28.8

22.0

15.3

11.5

9.1

7.5

6.2

5/16 in.

0.312 [8]

smaller v-open

ings

38.0

26.0

19.2

16.0

12.2

10.6

7.6

3/8 in.

0.375 [9.5]

Applications in red a not recommended

re

41.0

29.9

24.0

19.4

16.0

12.3

7/16 in.

0.438 [11.1]

45.2

35.0

28.0

24.0

17.0

1/2 in.

0.500 [12.7]

47.9

39.0

33.1

24.0

5/8 in.

0.625 [16]

69.5

58.0

42.2

3/4 in.

0.75 [19]

92.0

69.0

7/8 in.

0.875 [22]

104.0

1 in.

1.000 [25.4]

T = Material Thickness • V = V-Opening • MF = Minimum Flange Length • IR = Inside Radius NOTE: The above formulas and chart are for reference only.

The chart above is based on mild steel (tensile strength of 60,000 psi) formed to an included angle of 88 deg. See chart to the right for other materials.

Forming to other angles will change the MF, IR and tonnage.

Soft Brass

Soft Aluminum

Heattreated Aluminum Alloys Stainless Steel High-Strength Steel

Tons x 50 percent Tons x 50 percent Tons x 100 percent Tons x 150 percent Tons x 275 percent

amount of tonnage, followed by bottom bending then coining, which requires the greatest amount of force. Each bending method has benefits and lim- itations, but in general, bottom bend- ing requires at least twice the tonnage of air bending, and coining 5 to 10 times the tonnage of air bending.

Force Charts Explained

To assist in calculated needed ton- nage for press-brake operations, we present the accompanying air-bending force charts. The charts supply an esti- mated tonnage for air bending a given thickness of mild steel in a given V- opening. The numbers in the white and gray boxes running diagonally from the top left corner to the bottom right cor-

ner of each chart denote the estimated tons/ft. required to perform a certain bend. If planning to bottom-bend or coin, use the charts to find the air- bending force required, and then mul- tiply using the equations detailed above.

Important: The data in this chart is based on bending mild steel with a tensile strength of about 60,000 psi.

Start with the material to be formed as listed on the left and follow the row to the right until reaching the numbers. Notice that the tonnage numbers decrease from left to right, due to the fact that a larger V-opening requires less tonnage for that same material thickness. A shaded box represents the recommended V-opening for a partic- ular material thickness. A red-shaded

box indicates that the V-opening is too small for a given material thickness.

Tonnage limitations may dictate that a larger V-opening is required. But before jumping to a larger V-opening, consider how that will affect the form to be made. Will the larger V-opening accommodate the flange length or change the inside radius? Or, will a radius change in turn change the flat pattern or blank development?

Example 1: Bend 90 in. of 10-gauge mild steel with a 1-in. V

Follow the 10-gauge row in the Imperial V-Opening chart to the shaded box. The number is 8.4. This is the esti- mated tons/ft. required to form this application. Then follow that column straight up and notice that the V-opening

40 MetalForming/September 2016

www.metalformingmagazine.com

Tons/Ft.