Page 30 - MetalForming July 2016

P. 30

Selecting a New Automated

Selecting a New Automated

Plasma-Cutting System

Plasma-Cutting System

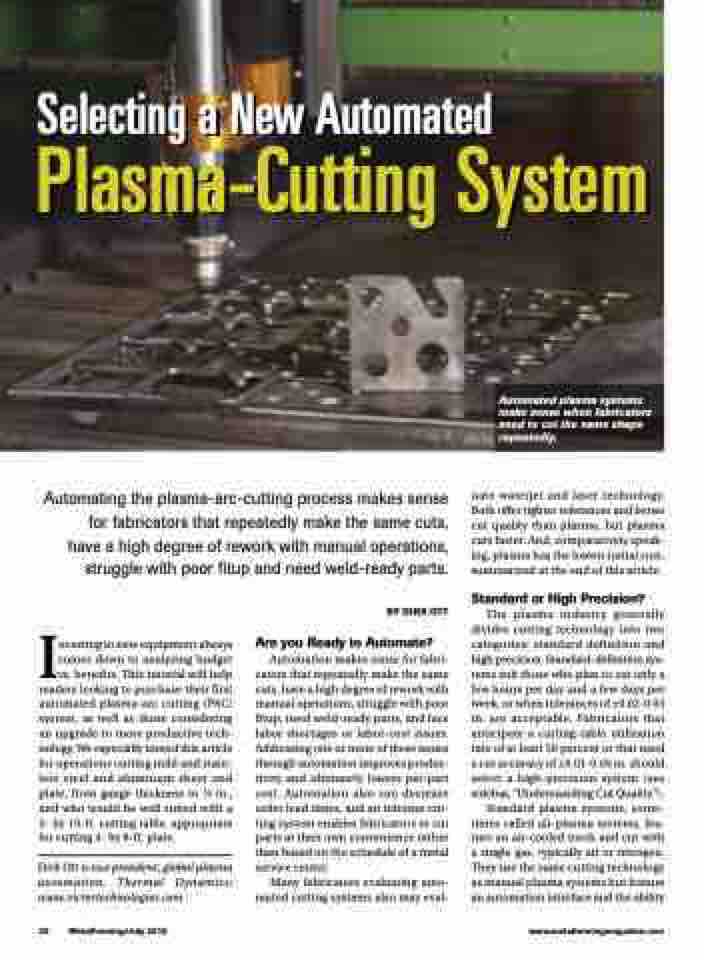

Automated plasma systems make sense when fabricators need to cut the same shape repeatedly.

Automating the plasma-arc-cutting process makes sense for fabricators that repeatedly make the same cuts, have a high degree of rework with manual operations, struggle with poor fitup and need weld-ready parts.

uate waterjet and laser technology. Both offer tighter tolerances and better cut quality than plasma, but plasma cuts faster. And, comparatively speak- ing, plasma has the lowest initial cost, summarized at the end of this article.

Standard or High Precision?

The plasma industry generally divides cutting technology into two categories: standard definition and high precision. Standard-definition sys- tems suit those who plan to cut only a few hours per day and a few days per week, or when tolerances of ±0.02-0.03 in. are acceptable. Fabricators that anticipate a cutting-table utilization rate of at least 50 percent or that need a cut accuracy of ±0.01-0.05 in. should select a high-precision system (see sidebar, “Understanding Cut Quality”).

Standard plasma systems, some- times called air-plasma systems, fea- ture an air-cooled torch and cut with a single gas, typically air or nitrogen. They use the same cutting technology as manual plasma systems but feature an automation interface and the ability

Investing in new equipment always comes down to analyzing budget vs. benefits. This tutorial will help readers looking to purchase their first automated plasma-arc cutting (PAC) system, as well as those considering an upgrade to more productive tech- nology. We especially intend this article for operations cutting mild and stain- less steel and aluminum sheet and plate, from gauge thickness to 1⁄4 in., and who would be well suited with a 5- by 10-ft. cutting table, appropriate for cutting 4- by 8-ft. plate.

Dirk Ott is vice president, global plasma automation, Thermal Dynamics; www.victortechnologies.com

BY DIRK OTT Are you Ready to Automate?

Automation makes sense for fabri- cators that repeatedly make the same cuts, have a high degree of rework with manual operations, struggle with poor fitup, need weld-ready parts, and face labor shortages or labor-cost issues. Addressing one or more of these issues through automation improves produc- tivity and ultimately lowers per-part cost. Automation also can decrease order lead times, and an inhouse cut- ting system enables fabricators to cut parts at their own convenience rather than based on the schedule of a metal service center.

Many fabricators evaluating auto- mated cutting systems also may eval-

28 MetalForming/July 2016

www.metalformingmagazine.com