Page 28 - MetalForming July 2016

P. 28

The Case for

High-Def

Plasma Cutting

of Sheet and Plate

Gas mixing at the cutting head, to practically eliminate purging between setups; a high-speed swirling assist gas that produces nearly perfectly square cut faces; and the ability to cut stainless steel with oxidation-free edges have led this fab shop into the next generation of plasma-arc cutting.

BY BRAD F. KUVIN, EDITOR

Economical yet productive, fast yet accurate, and spe- cialized yet diverse—all terms defining the new age in plasma-arc cutting ushered in by a high-definition plasma-arc cutting (PAC) machine that recently landed on the plant floor of Southwest & Associates, Inc. (SAI). Brought in late in 2015 to replace an aging PAC machine, the new machine, not surprisingly, offers technology enhancements that have SAI officials gloating over enriched capabilities. These include:

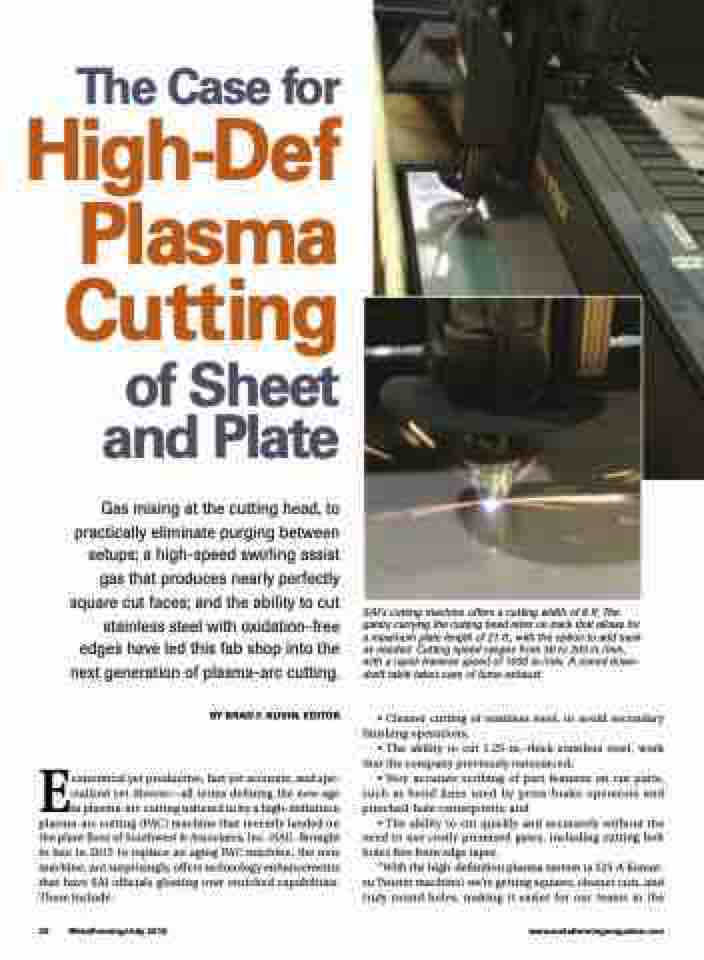

SAI’s cutting machine offers a cutting width of 8 ft. The gantry carrying the cutting head rides on track that allows for a maximum plate length of 21 ft., with the option to add track as needed. Cutting speed ranges from 30 to 200 in./min., with a rapid-traverse speed of 1000 in./min. A zoned down- draft table takes care of fume exhaust.

• Cleaner cutting of stainless steel, to avoid secondary finishing operations;

• The ability to cut 1.25-in.-thick stainless steel, work that the company previously outsourced;

• Very accurate scribing of part features on cut parts, such as bend lines used by press-brake operators and punched-hole centerpoints; and

• The ability to cut quickly and accurately without the need to use costly premixed gases, including cutting bolt holes free from edge taper.

“With the high-definition plasma system (a 525-A Komat- su Twister machine) we’re getting squarer, cleaner cuts, and truly round holes, making it easier for our teams in the

26 MetalForming/July 2016

www.metalformingmagazine.com