Page 50 - MetalForming March 2016

P. 50

Change the Hydraulic Fluid

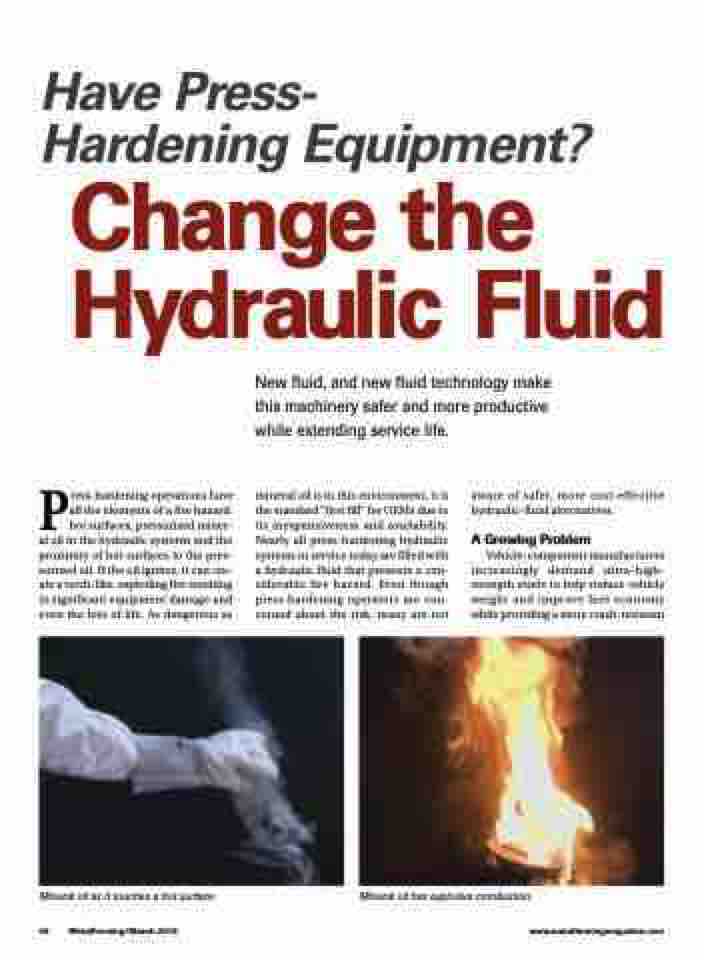

Press-hardening operations have all the elements of a fire hazard: hot surfaces, pressurized miner- al oil in the hydraulic systems and the proximity of hot surfaces to the pres- surized oil. If the oil ignites, it can cre- ate a torch-like, exploding fire resulting in significant equipment damage and even the loss of life. As dangerous as

mineral oil is in this environment, it is the standard “first fill” for OEMs due to its inexpensiveness and availability. Nearly all press-hardening hydraulic systems in service today are filled with a hydraulic fluid that presents a con- siderable fire hazard. Even though press-hardening operators are con- cerned about the risk, many are not

aware of safer, more cost-effective hydraulic-fluid alternatives.

A Growing Problem

Vehicle-component manufacturers increasingly demand ultra-high- strength steels to help reduce vehicle weight and improve fuel economy while providing a more crash-resistant

Mineral oil as it touches a hot surface.

Mineral oil has explosive combustion.

48 MetalForming/March 2016

www.metalformingmagazine.com

New fluid, and new fluid technology make this machinery safer and more productive while extending service life.