Page 52 - MetalForming March 2016

P. 52

Change the Hydraulic Fluid

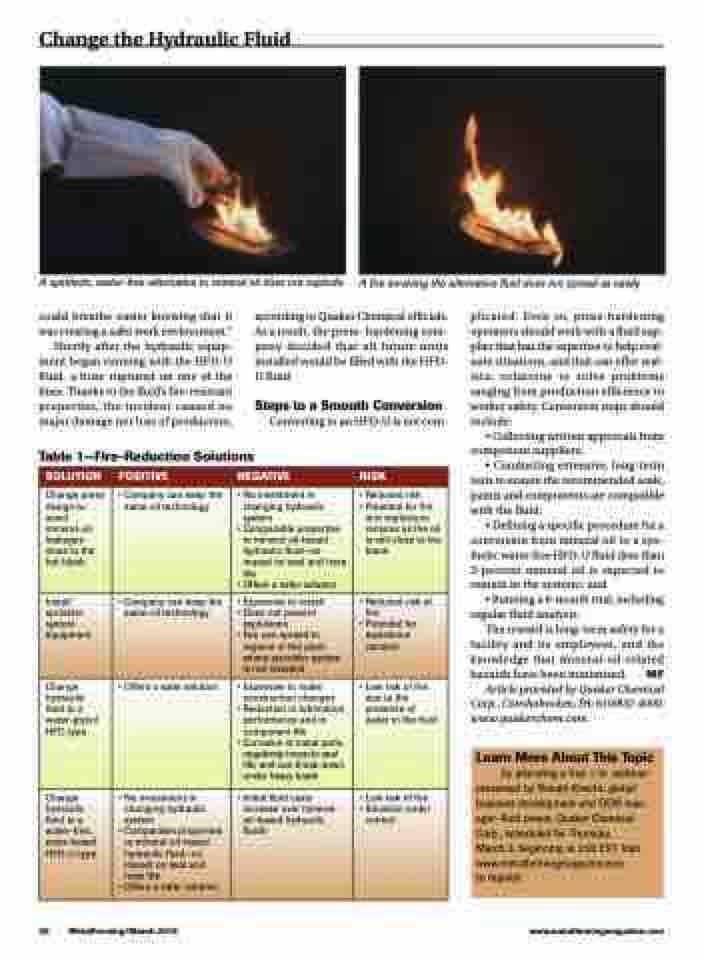

A synthetic, water-free alternative to mineral oil does not explode. A fire involving the alternative fluid does not spread as easily.

could breathe easier knowing that it was creating a safer work environment.” Shortly after the hydraulic equip- ment began running with the HFD-U fluid, a hose ruptured on one of the lines. Thanks to the fluid’s fire-resistant properties, the incident caused no major damage nor loss of production,

Table 1—Fire-Reduction Solutions

according to Quaker Chemical officials. As a result, the press- hardening com- pany decided that all future units installed would be filled with the HFD- U fluid.

Steps to a Smooth Conversion

Converting to an HFD-U is not com-

plicated. Even so, press-hardening operators should work with a fluid sup- plier that has the expertise to help eval- uate situations, and that can offer real- istic solutions to solve problems ranging from production efficiency to worker safety. Conversion steps should include:

• Collecting written approvals from component suppliers;

• Conducting extensive, long-term tests to ensure the recommended seals, paints and components are compatible with the fluid;

• Defining a specific procedure for a conversion from mineral oil to a syn- thetic water-free HFD-U fluid (less than 3-percent mineral oil is expected to remain in the system); and

• Running a 6-month trial, including regular fluid analysis.

The reward is long-term safety for a facility and its employees, and the knowledge that mineral-oil-related hazards have been minimized. MF

Article provided by Quaker Chemical Corp., Conshohocken, PA; 610/832-4000; www.quakerchem.com.

Learn More About This Topic

...by attending a free 1-hr. webinar presented by Ronald Knecht, global business development and OEM man- ager–fluid power, Quaker Chemical Corp., scheduled for Thursday,

March 3, beginning at 2:00 EST. Visit www.metalformingmagazine.com

to register.

SOLUTION

POSITIVE

NEGATIVE

RISK

Change press design to avoid mineral-oil leakages close to the hot blank

• Company can keep the same oil technology

• No investment in changing hydraulic system

• Comparable properties to mineral oil-based hydraulic fluid—no impact on seal and hose life

• Offers a safer solution

• Reduced risk

• Potential for fire

and explosions remains as the oil is still close to the blank

Install sprinkler system equipment

• Company can keep the same oil technology

• Expensive to install

• Does not prevent

explosions

• Fire can spread to

regions of the plant where sprinkler system is not installed

• Reduced risk of fire

• Potential for explosions remains

Change hydraulic fluid to a water-glycol HFC-type

• Offers a safer solution

• Expensive to make construction changes

• Reduction in lubrication performance and in component life

• Corrosion of metal parts, negatively impacts seal life, and can break down under heavy loads

• Low risk of fire due to the presence of water in the fluid

Change hydraulic fluid to a water-free, ester-based HFD-U type

• No investment in changing hydraulic system

• Comparable properties to mineral oil-based hydraulic fluid—no impact on seal and hose life

• Offers a safer solution

• Initial fluid costs increase over mineral- oil-based hydraulic fluids

• Low risk of fire • Situation under

control

50 MetalForming/March 2016

www.metalformingmagazine.com