Page 48 - MetalForming March 2016

P. 48

Hot-Forming Die Design and Build

certain areas of the part and rigidity in others. Ductility helps absorb crash impact energy while rigidity helps the component resist collapse during a collision. In AP&T systems, hot-formed parts are quenched while still in pro- duction die sets, which requires design- ing the dies for rapid water-cooling. For austenite-martensite transforma- tions, the rate of cooling is critical.

Quenching newly formed parts in the forming dies requires three sets of analyses with Pam-Stamp, Wigren explains.

“Our first analyses are thermal/fea- sibility, based on the assumption that cooling water is located 10 mm from the die surface,” he says. “Next comes design and analysis of the cooling system.”

Inside of the dies, channels carry water to absorb the heat produced dur- ing forming, when temperatures can reach 450 C in just a few seconds. A third set of simulations verifies that the entire quenching process will meet

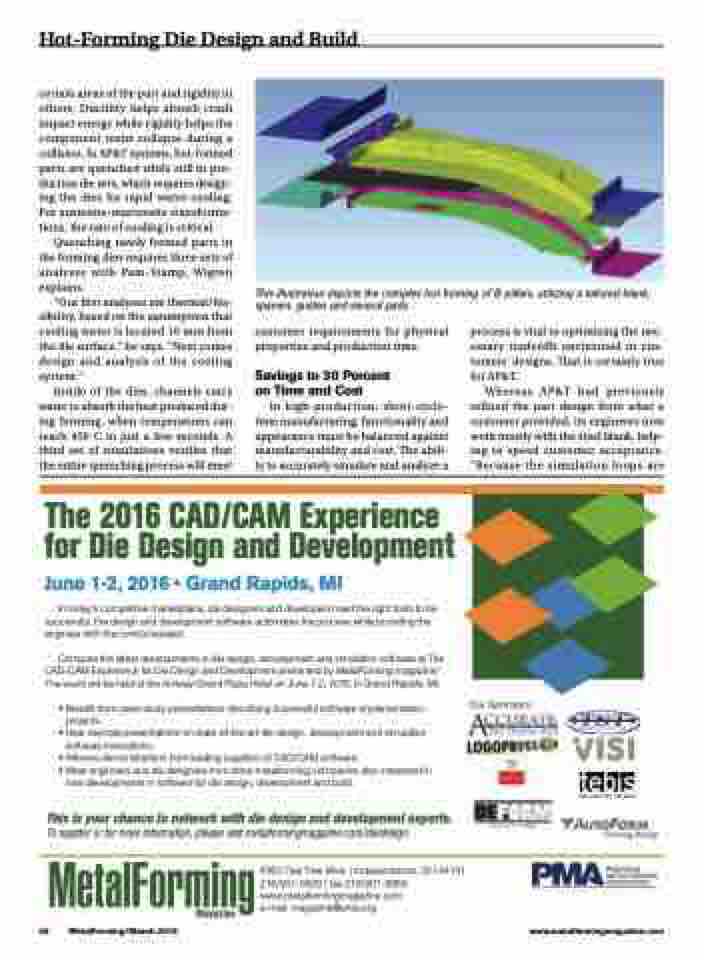

This illustration depicts the complex hot forming of B-pillars, utilizing a tailored blank, spacers, guides and several pads.

customer requirements for physical properties and production time.

Savings to 30 Percent on Time and Cost

In high-production, short-cycle- time manufacturing, functionality and appearance must be balanced against manufacturability and cost. The abili- ty to accurately simulate and analyze a

process is vital to optimizing the nec- essary tradeoffs envisioned in cus- tomers’ designs. That is certainly true for AP&T.

Whereas AP&T had previously refined the part design from what a customer provided, its engineers now work mostly with the steel blank, help- ing to speed customer acceptance. “Because the simulation loops are

The 2016 CAD/CAM Experience

for Die Design and Development

June 1-2, 2016 • Grand Rapids, MI

In today’s competitive marketplace, die designers and developers need the right tools to be successful. Die design and development software automates the process while providing the engineer with the control needed.

Compare the latest developments in die design, development and simulation software at The CAD/CAM Experience for Die Design and Development presented by MetalForming magazine! The event will be held at the Amway Grand Plaza Hotel on June 1-2, 2016, in Grand Rapids, MI.

• Benefit from case-study presentations describing successful software-implementation projects.

• Hear keynote presentations on state-of-the-art die design, development and simulation software innovations.

• Witness demonstrations from leading suppliers of CAD/CAM software.

• Meet engineers and die designers from other metalforming companies also interested in

new developments in software for die design, development and build.

This is your chance to network with die design and development experts.

To register or for more information, please visit metalformingmagazine.com/diedesign.

6363 Oak Tree Blvd. | Independence, OH 44131 216/901-8800 | fax 216/901-9669 www.metalformingmagazine.com

e-mail: magazine@pma.org

Our Sponsors:

46 MetalForming/March 2016

www.metalformingmagazine.com